Pre-assembled substation room structure

A prefabricated substation and transformer room technology, applied in the field of power substations, can solve the problems that the cooling conditions of the box-type substation cannot meet the cooling requirements of the transformer, the working efficiency and service life of the equipment are reduced, and the maintenance and capacity expansion are inconvenient. Modular installation, reasonable structural arrangement, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

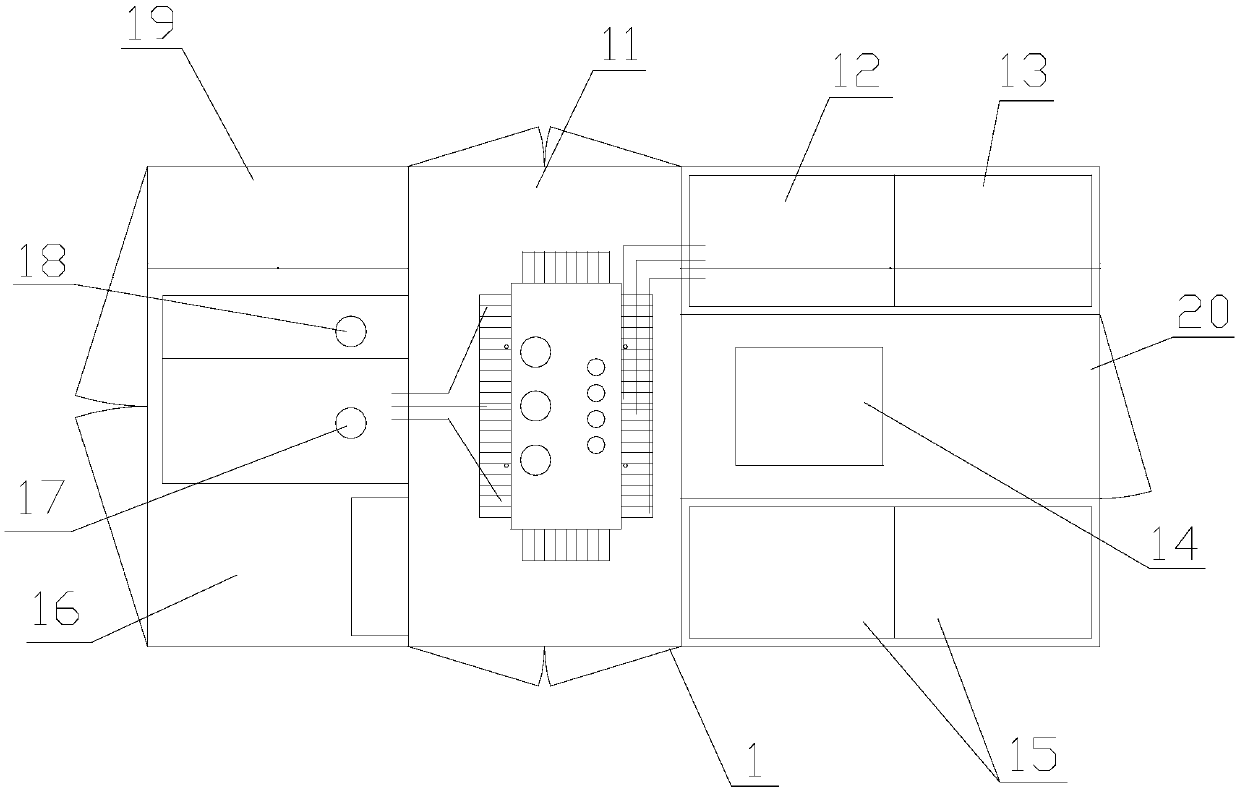

[0012] Such as figure 1 As shown, a prefabricated substation room structure includes a box body 1 made of non-metallic materials. The box body 1 is provided with a high-voltage chamber 19, a transformer room 11 and a low-voltage chamber 20. The bottom of the box body 1 is provided with a bottom The bottom frame is provided with a bottom surface; the transformer chamber 11 is located in the middle part of the box, and the two sides of the transformer chamber 11 are respectively provided with a high-voltage chamber 19 and a low-voltage chamber 20, and the high-voltage chamber 19 is respectively provided with a high-voltage inlet Line holes 18 and high-voltage feeder holes 17, the low-voltage chamber 20 is respectively provided with a low-voltage metering main cabinet 12 and a low-voltage outlet cabinet 13.

[0013] In this embodiment, the high-voltage chamber 19 is also provided with a load monitoring device 16, and the low-voltage chamber 20 is provided with a reserved installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com