Process for pneumatically conveying a powdery material

A powdery, pneumatic technology, applied in the direction of conveying bulk materials, chemical instruments and methods, conveyors, etc., can solve problems such as restoring normal pressure drop, amplification, etc., to improve efficiency and safety, and avoid inappropriate working frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

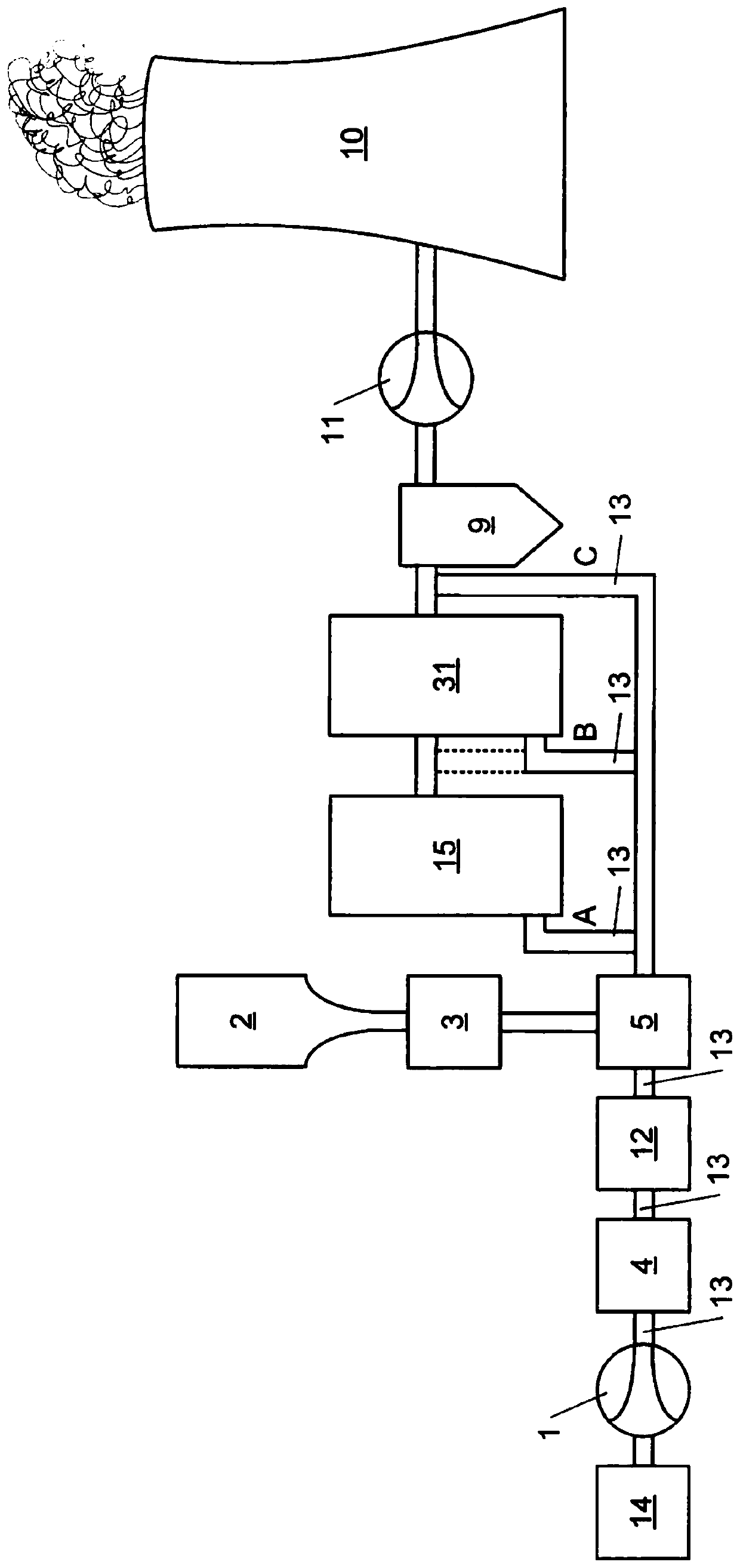

[0276] Trials were carried out on an industrial scale in a power plant to evaluate the effectiveness of the invention in pneumatically conveying a powdered hydrated lime adsorbent, especially with regard to fluctuations in the pressure drop within the plant.

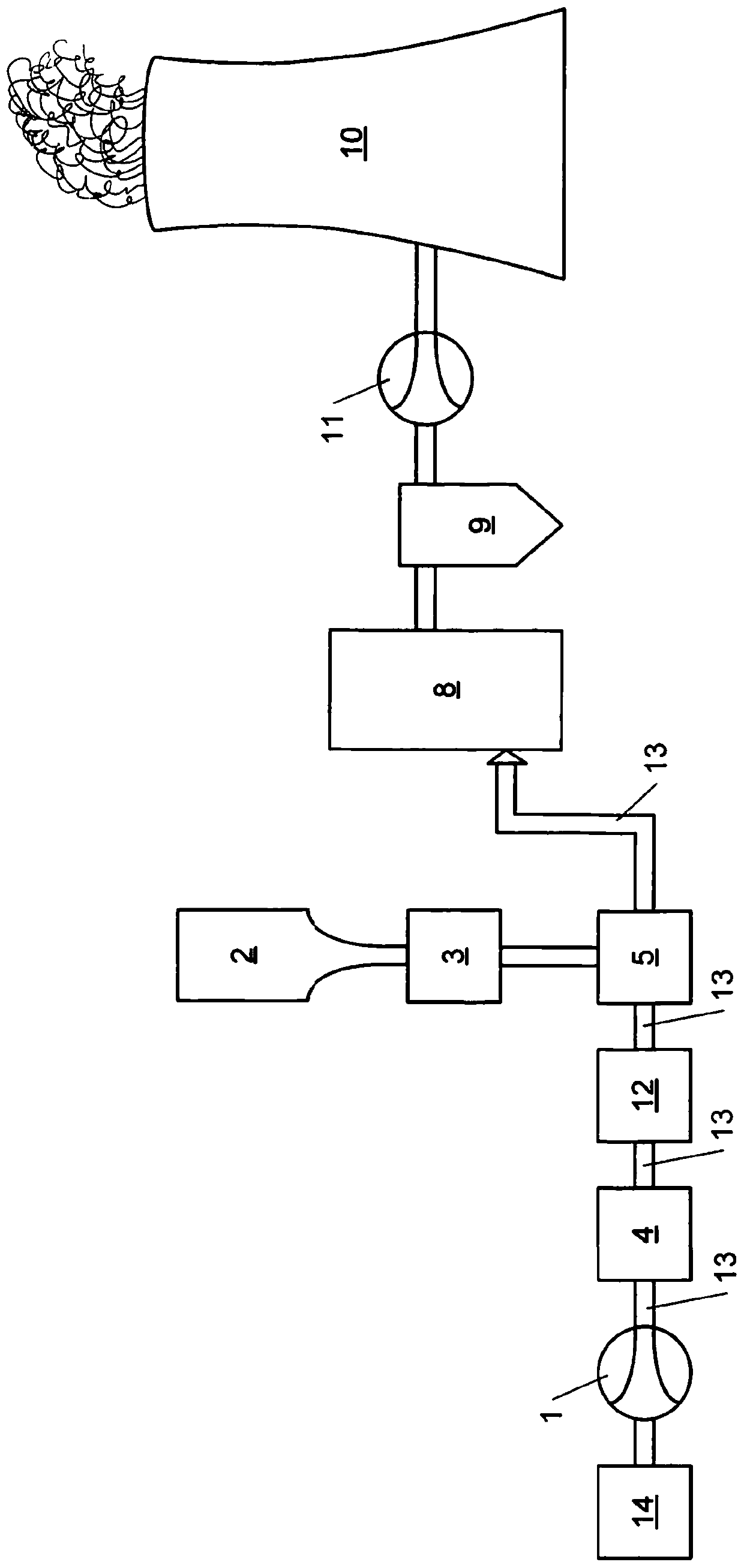

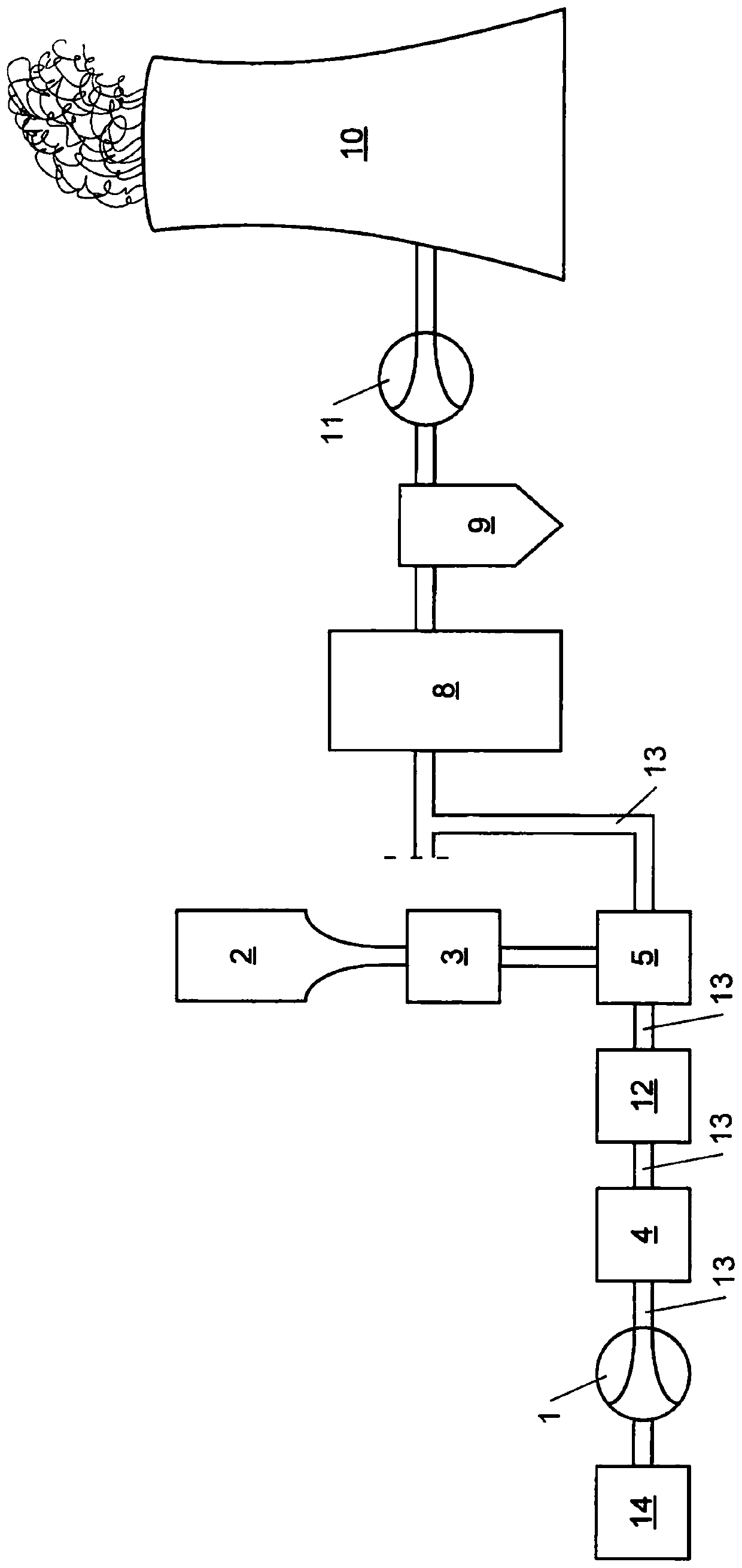

[0277] Such as Figure 7 As shown, the electrical equipment used in these tests consisted of a burner (15), a furnace (31) for burning coal connected to a flue gas duct, wherein the flue gas produced in the furnace is directed to the electrostatic precipitator (9), then to the scrubber (32) and further to the chimney (10).

[0278] Hydrated lime is injected into the flue gas duct of the power plant before the electrostatic precipitator and before the chimney for capturing gaseous pollutants, especially SO 2 . Such an adsorbent is a high surface area hydrated lime as disclosed in WO9714650.

[0279] The plant also comprises a storage tank (2) for said powdered hydrated lime, said tank being connected to the furnace by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com