Windmill tower damping system based on electrorheological effect

A vibration reduction system and electrorheological technology are applied in wind turbines, wind turbine control, wind turbine monitoring and other directions, which can solve problems such as low technical difficulty, achieve low energy consumption, facilitate application and development, and avoid resonance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

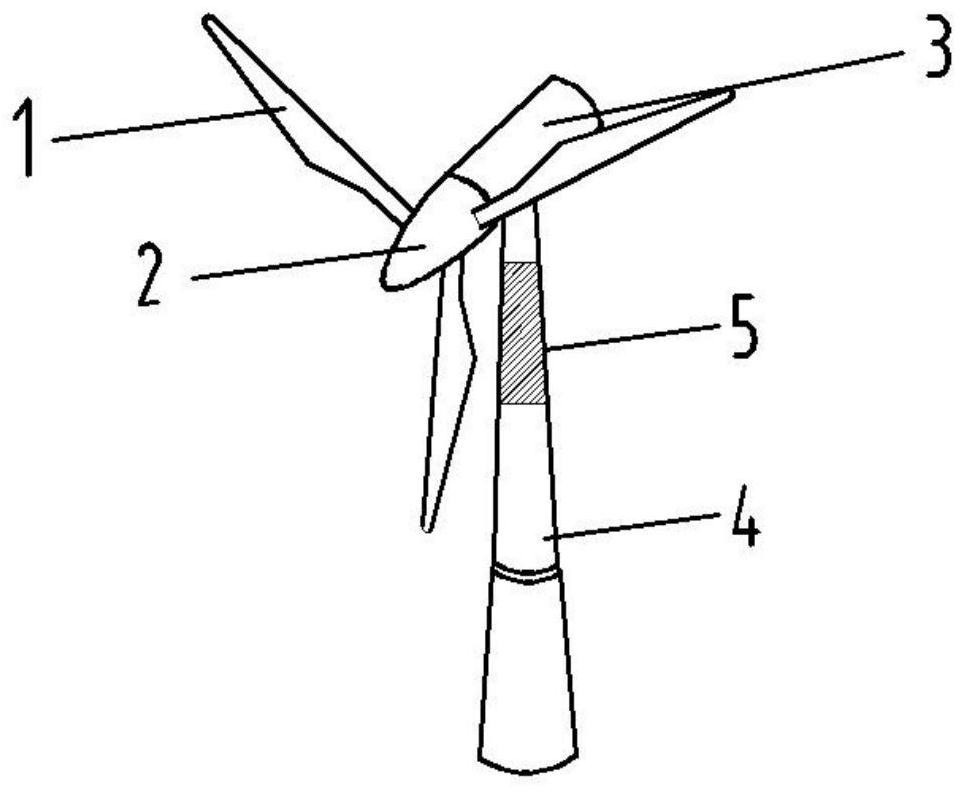

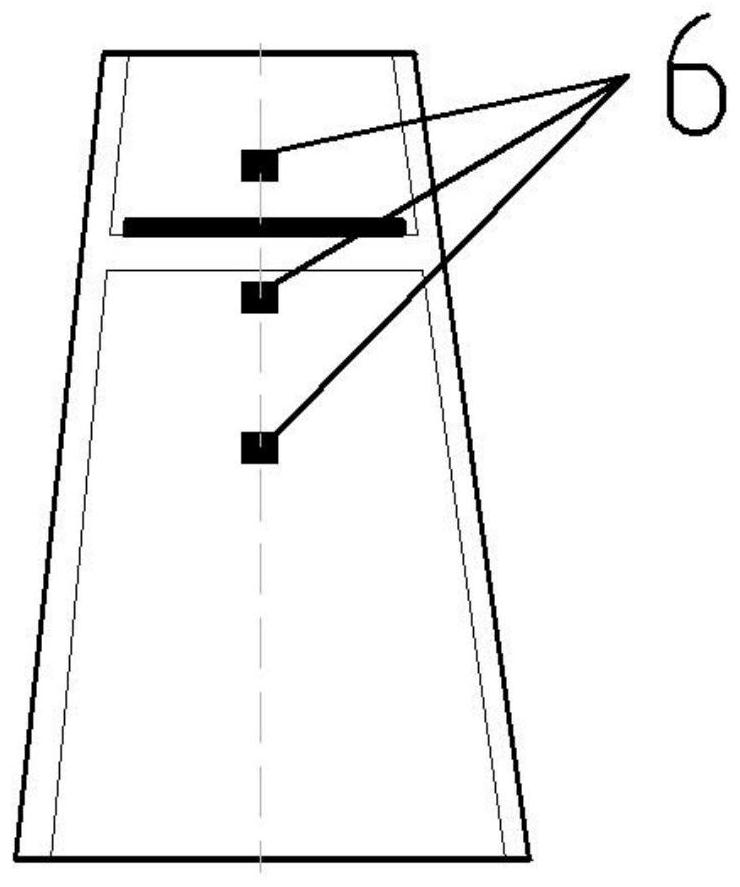

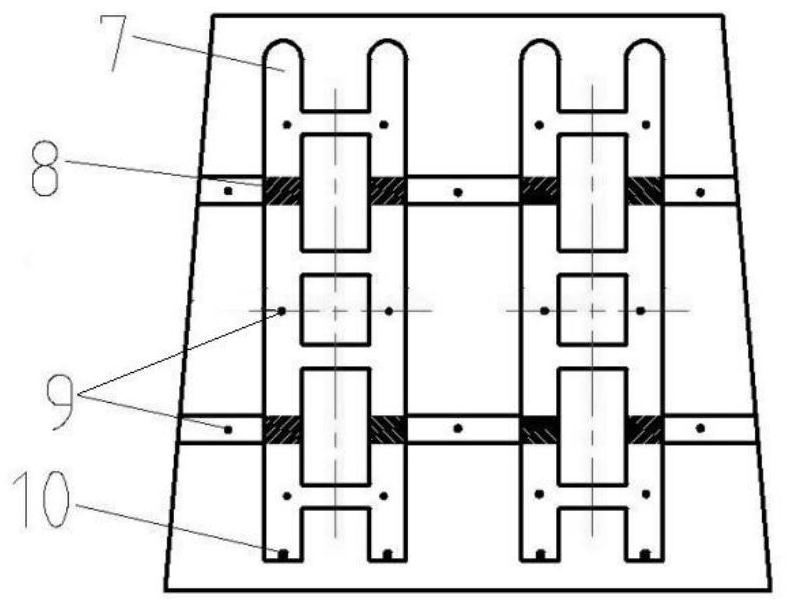

[0034] In this example, see Figure 1 to Figure 9 , a wind turbine tower vibration damping system based on the electrorheological effect, including a vibration sensor 6, an electrorheological fluid pouring pipe 7 and an electrical control system; 2 to 3 of the vibration sensors 6 are distributed along the vertical direction and pasted on the wind force The upper outer surface of the machine tower; the electrorheological fluid pouring pipe 7 is fixed on the upper wall of the wind turbine tower in a fence shape; the electrical control system is fixedly installed in the wind turbine tower through an electrical board 11; The vibration sensor 6 is electrically connected to the electrorheological fluid pouring pipe 7 through the electrical control system; when the vibration sensor 6 transmits a signal indicating that the vibration is too large, the electrical control system controls the electrorheological fluid pouring pipe 7 to turn on the power, so that the electrorheological fluid...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0037] In this embodiment, the electrical control system includes an A / D conversion module, a programmable logic controller PLC, a D / A conversion module, a relay and its corresponding switch, a large-capacity lithium battery, and is also equipped with a relay The corresponding switch connects the electrodes of the electrorheological fluid pouring tube 7 .

Embodiment 3

[0039] In this embodiment, a wind turbine tower vibration damping system based on the electrorheological effect includes a vibration sensor 6, an A / D conversion module, a programmable logic controller PLC, a D / A conversion module, a current transmission device, a large-capacity Lithium battery, electrorheological fluid pouring tube 7, connecting steel plate 8, pressing steel ring 13, pressing connecting plate 14, and glue-free nails 15.

[0040] Such asfigure 1 As shown, the main components of the wind generator include the wind turbine blade 1, the wind deflector 2, the nacelle 3, and the tower 4, and the present invention is installed at the arrangement position 5 of the device.

[0041] Such as figure 2 As shown, the vibration sensors 6 are distributed on the surface of the tower in a straight line, and there are three in total. Figure 4 The flow chart of the working process can clearly see that the vibration sensor is connected to the A / D module through the data line, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com