Methods of feeding the extruder

An extruder and material feeding technology, which is applied in the direction of chemical instruments and methods, mixers, mixer accessories, etc., can solve the problems of costly leather segmentation, etc., and achieve the effect of preventing the danger of intruders and making it easy to introduce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

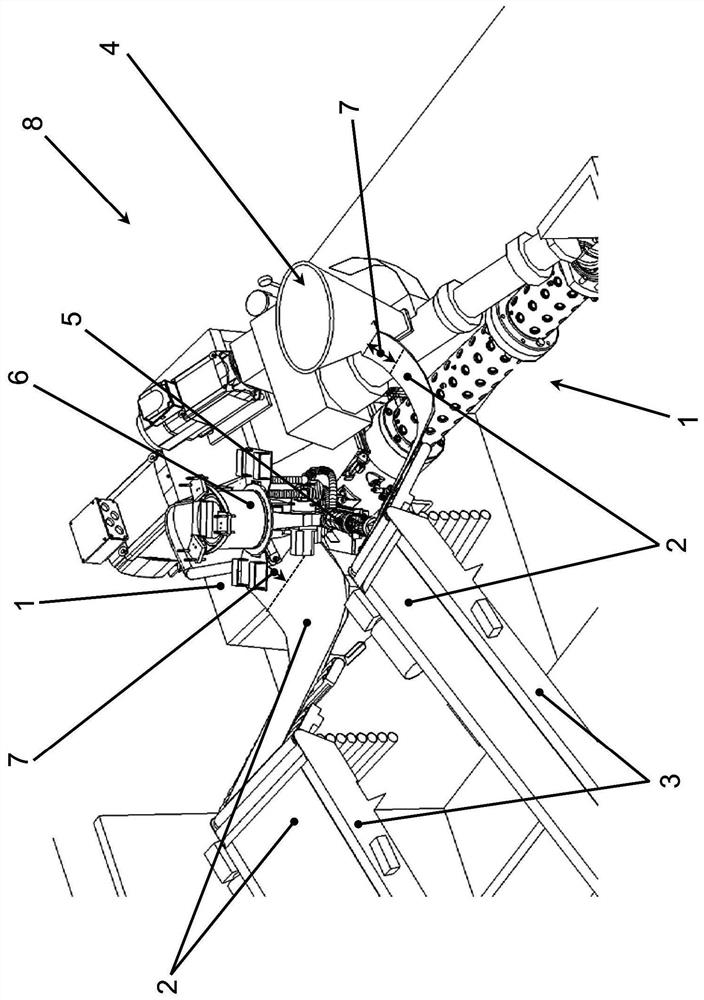

[0037] figure 1 A possible arrangement when carrying out the method according to the invention is shown. Shown is an extruder 1 designed as a coextruder with two material feeds 4 . The starting regions 7 of the web 2 are introduced into the two material infeeds 4 by means of the tool 5 designed as a roller gripper of the handling device 6 designed as a robot, wherein these starting regions are first picked up by the conveyor 3 and processing. It should be noted that only a feed of the web 2 directed in the direction of introduction of the material infeed 4 is possible by means of the tool 5 embodied as a roller gripper. In a preceding step, these webs 2 are transported at a distance from the material infeed 4 into the region of the material infeed 4 by means of a conveyor 3 embodied as a conveyor belt. Here, the extruder 1 , the individual conveyors 3 and the processing device 6 form a production plant 8 .

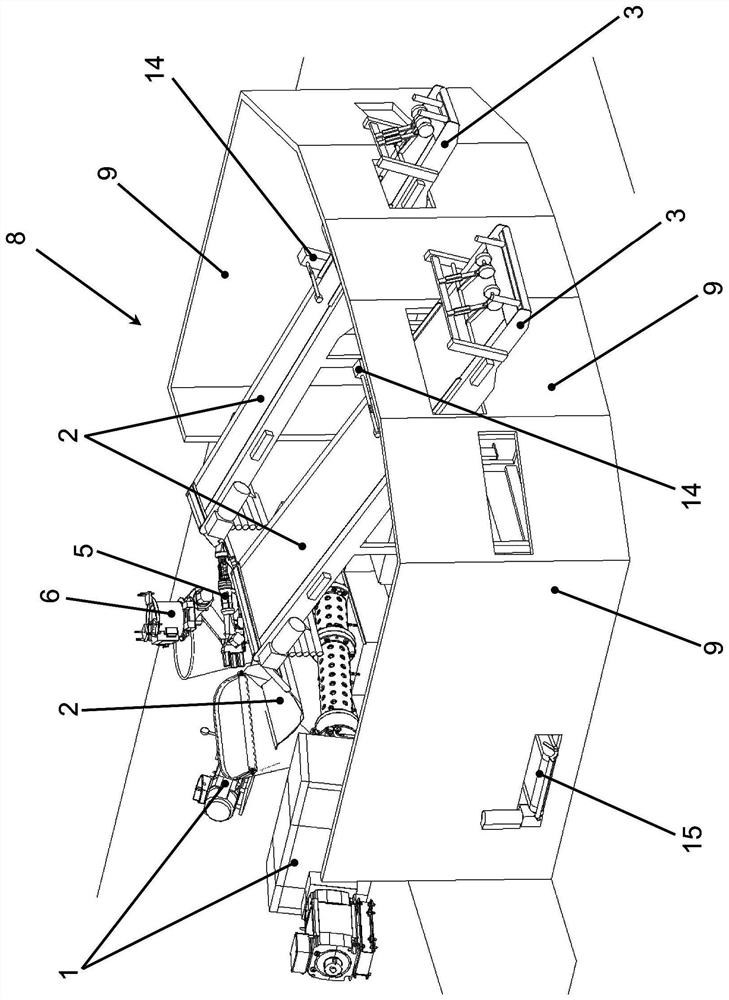

[0038] figure 2 A diagram of a manufacturing plant 8 is shown w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com