Processing technology of fixed denture

A processing technology and fixed denture technology, which is applied in medical science, dental prosthesis, dentistry, etc., can solve the problems of endangering the health of operators and the inability to effectively process powder, and achieve the effect of reducing labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

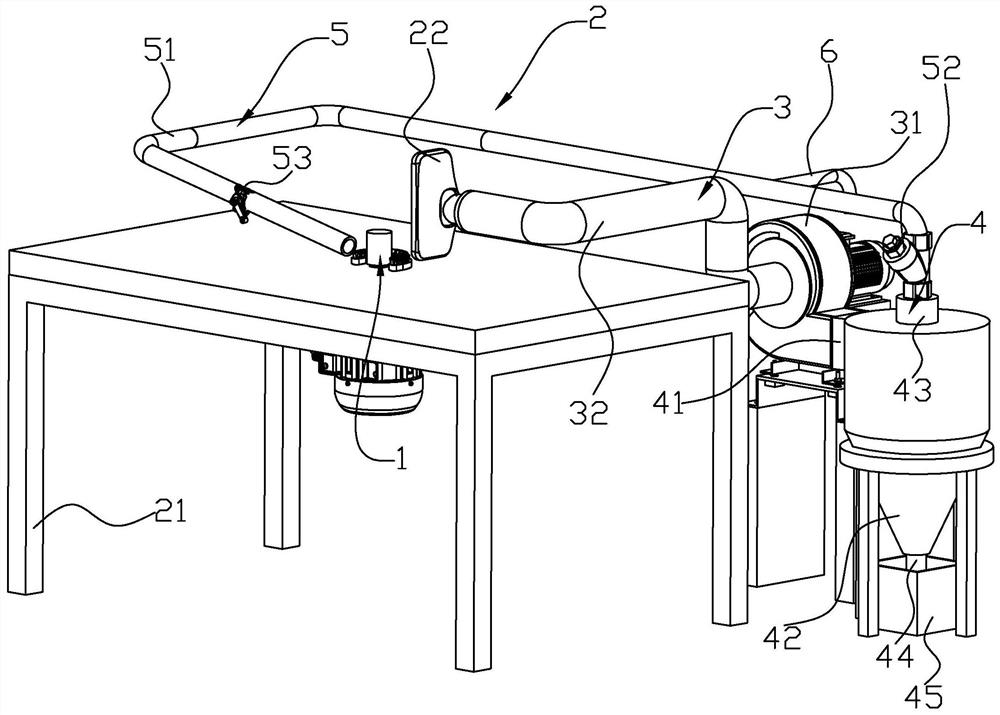

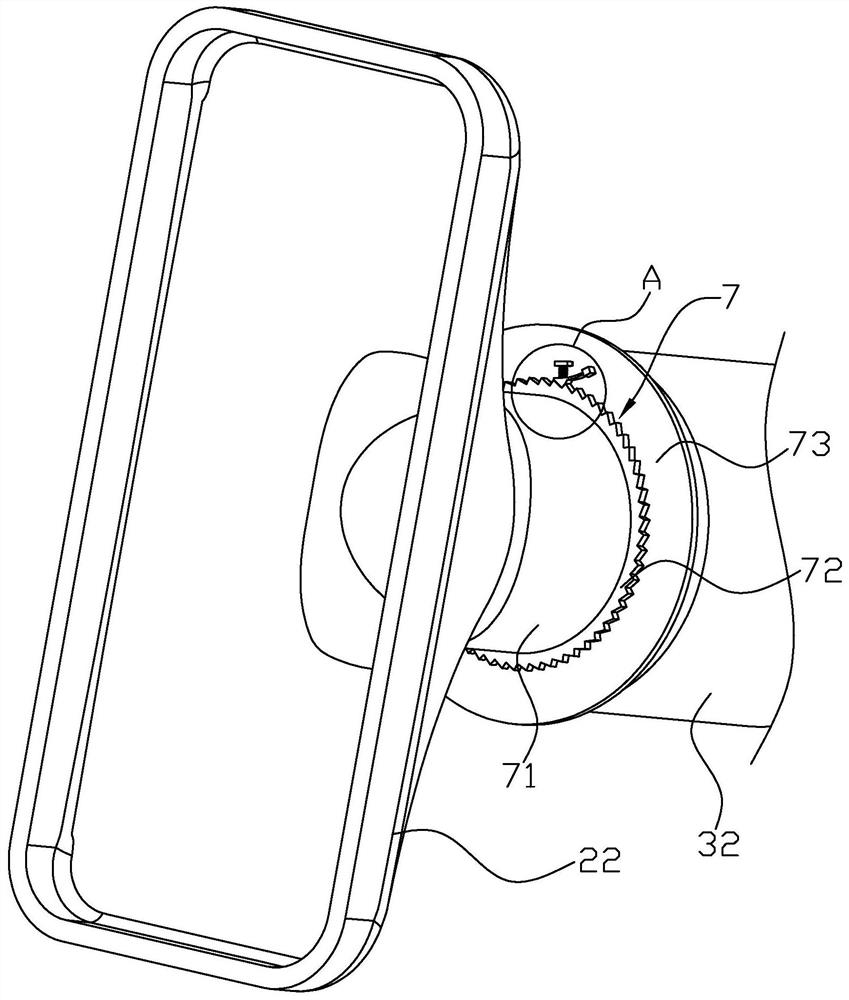

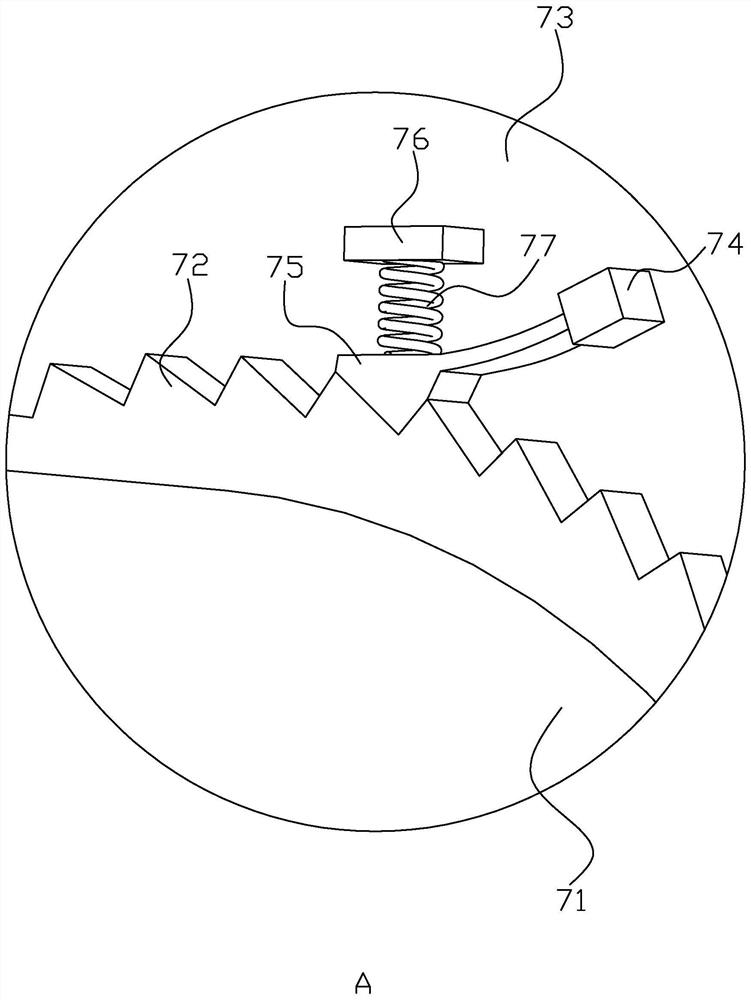

[0031] Embodiment: a kind of processing technology of fixed denture, as figure 1 shown, including the following steps:

[0032] a. Model reception: receive the oral cavity model;

[0033] b. Disinfection: Disinfect the oral model to remove some impurities and bacteria on the model;

[0034] c. Inspection: check the oral model to determine whether the oral model meets the standards;

[0035] d. Seed nails: copy the oral model to form a denture model, drill multiple holes on the denture model, and put metal nails in each hole; then saw the mold, remove the excess part inside the model, and form a horseshoe shape;

[0036] e. Reshaping: The edge of the upper articulator is trimmed, mainly through the grinding machine 1, and the powder is collected by the powder removal mechanism 2 during the grinding process of the denture model; then the undercut and the incomplete position of the model are filled;

[0037] f. Wax-up: use wax to create the outline of the denture;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com