Industrial waste gas treatment apparatus

A technology for treating device and industrial waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of incomplete waste gas treatment, failure to divide waste gas, poor effect, etc. The effect of helping the circulation and reducing the dead angle of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the invention will be further described:

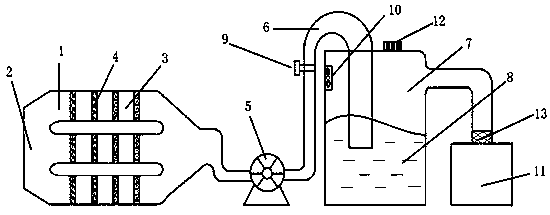

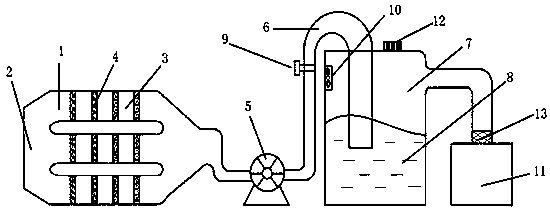

[0015] Such as figure 1 As shown, an industrial exhaust gas treatment device includes an exhaust gas adsorption box, an air inlet is provided on one side of the exhaust gas adsorption box, and a plurality of channels are provided inside, and several activated carbon adsorption nets are provided on each channel. The other side of the exhaust gas adsorption box is connected with an air extractor, and the other side of the air extractor communicates with the treatment liquid in the exhaust gas treatment box through a U-shaped pipeline. The U-shaped pipeline is provided with a control valve. A fan is provided on one side of the waste gas treatment box, and a motor is provided on the top. The fan is connected to the motor through wires, and the other side of the waste gas treatment box is provided with a waste gas collection box. There is a drying device at the junction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com