Water treatment photocatalyst and preparation method thereof

A photocatalyst and water treatment technology, applied in physical/chemical process catalysts, chemical instruments and methods, water treatment of special compounds, etc., can solve problems such as easy self-corrosion, silver phosphate instability, etc., to avoid self-instability, structure Stable properties and excellent adsorption/decomposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

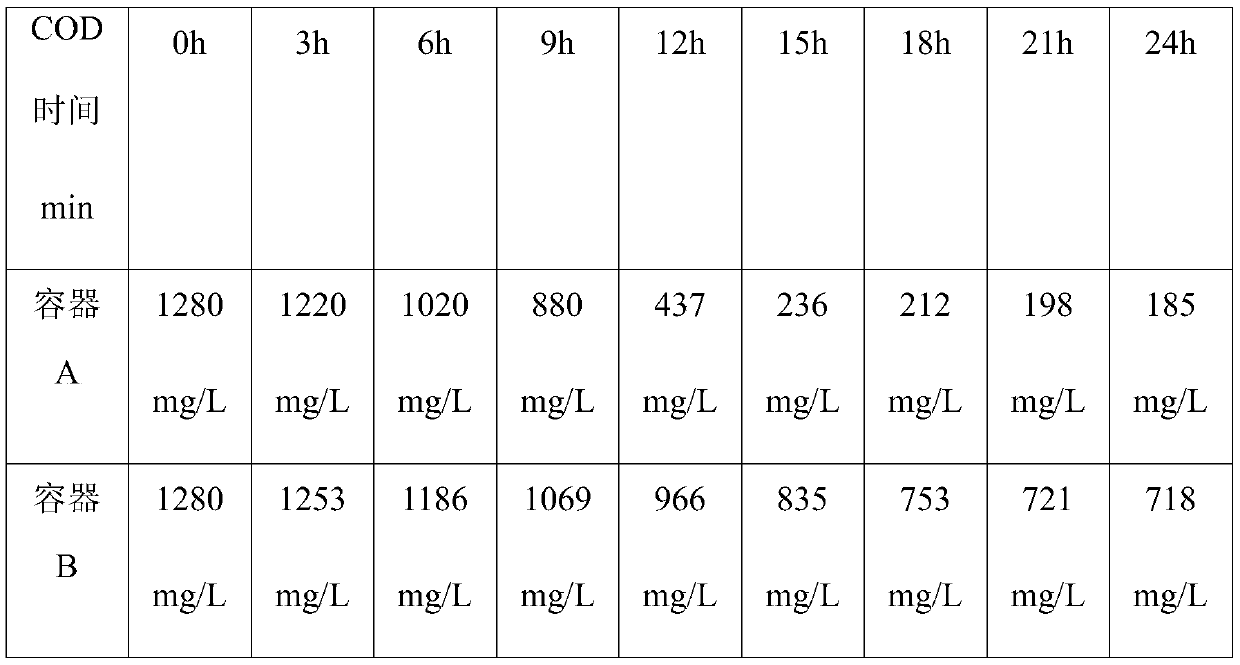

Examples

Embodiment 1

[0018] Embodiment 1: A photocatalyst for water treatment, specifically supporting silver tantalum niobate sodium / silver molybdate / modified silver phosphate composite material particles in spherical porous hydroxyapatite.

[0019] Its preparation method comprises the following steps:

[0020] (1) Add soluble phosphate into deionized water, ultrasonically disperse, add silver acetate solution and stir for 0.5h to obtain mixed solution A; then add a small amount of nickel-iron alloy to mixed solution A, continue stirring for 1.5h, and vacuum filter , and washed with deionized water, and then the filtered solid was dried to obtain modified silver phosphate for subsequent use; wherein, the nickel-iron alloy adopts FeNi 2 0 powder, the mass ratio of the added nickel-iron alloy to the mixed solution A is 1:170;

[0021] (2) After mixing sodium tantalum niobate, silver molybdate, and modified silver phosphate in a mass ratio of 1.3:1.7:0.6, add them to deionized water, ultrasonically...

Embodiment 2

[0023] Embodiment 2: a kind of preparation method of water treatment photocatalyst comprises the following steps:

[0024] (1) Add soluble phosphate into deionized water, ultrasonically disperse, add silver acetate solution and stir for 0.5h to obtain mixed solution A; then add a small amount of nickel-iron alloy to mixed solution A, continue stirring for 1.8h, and vacuum filter , and washed with deionized water, and then the filtered solid was dried to obtain modified silver phosphate for subsequent use; wherein, the nickel-iron alloy adopts FeNi 2 0 powder, the mass ratio of the added nickel-iron alloy to the mixed solution A is 1:190;

[0025] (2) After mixing sodium tantalum niobate, silver molybdate, and modified silver phosphate in a mass ratio of 2:2.2:1.1, add them to deionized water, ultrasonically disperse, mix and stir for 2 hours, and then heat at 90 degrees Dry under normal pressure, then place the dried mixture in a crucible furnace and roast for 5 hours to obta...

Embodiment 3

[0027] Embodiment 3: a kind of preparation method of water treatment photocatalyst comprises the following steps:

[0028] (1) Add soluble phosphate into deionized water, ultrasonically disperse, add silver acetate solution and stir for 0.5h to obtain mixed solution A; then add a small amount of nickel-iron alloy to mixed solution A, continue stirring for 2 hours, and vacuum filter, And wash with deionized water, and then dry the filtered solid to obtain modified silver phosphate for subsequent use; wherein, the nickel-iron alloy adopts FeNi 2 0 powder, the mass ratio of the added nickel-iron alloy to the mixed solution A is 1:250;

[0029] (2) After mixing sodium tantalum niobate, silver molybdate, and modified silver phosphate in a mass ratio of 2.2:3.4:1.3, add them to deionized water, ultrasonically disperse, mix and stir for 3 hours, and then Dry under normal pressure, then place the dried mixture in a crucible furnace and roast for 8 hours to obtain a silver tantalum ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com