Flexible pure aluminum foil and glass fiber composite material machining mold

A technology of glass fiber and composite materials, which is applied in metal processing and other directions, can solve the problems of being unable to bear the extrusion force of the product, unable to detect defective products, and unable to achieve the effect, so as to eliminate defective products, excellent shielding performance, and meet product costs. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

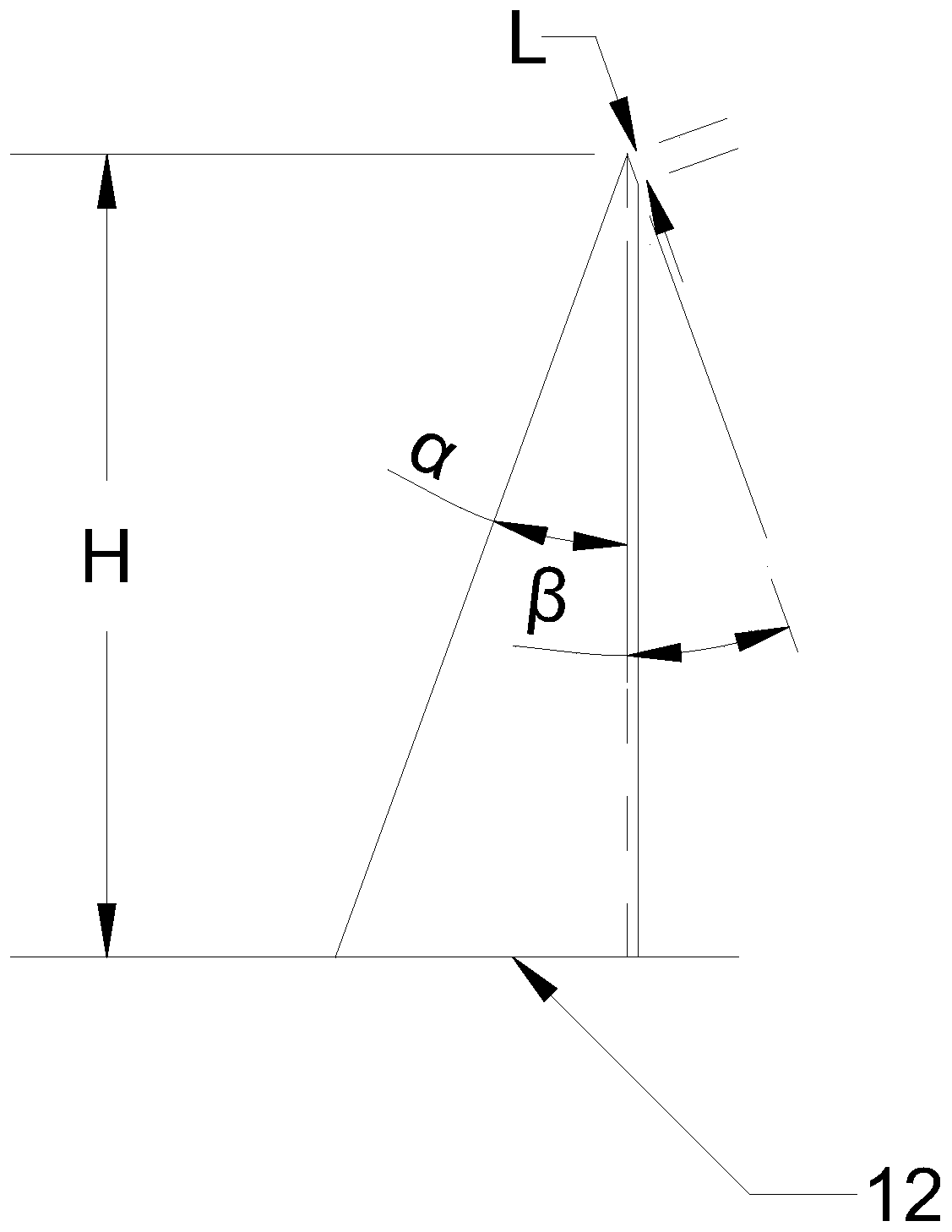

[0033] image 3 A schematic diagram of the blade. Such as image 3 As shown, the bending height H of the blade 12 is 1.5T, the purpose is to reduce the contact surface between the blade 12 and the incision, so as to reduce friction. The inner included angle α and the outer included angle β of the blade 12 are both 20°, and the length L of the edge of the blade 12 is 0.06 mm to prevent chipping.

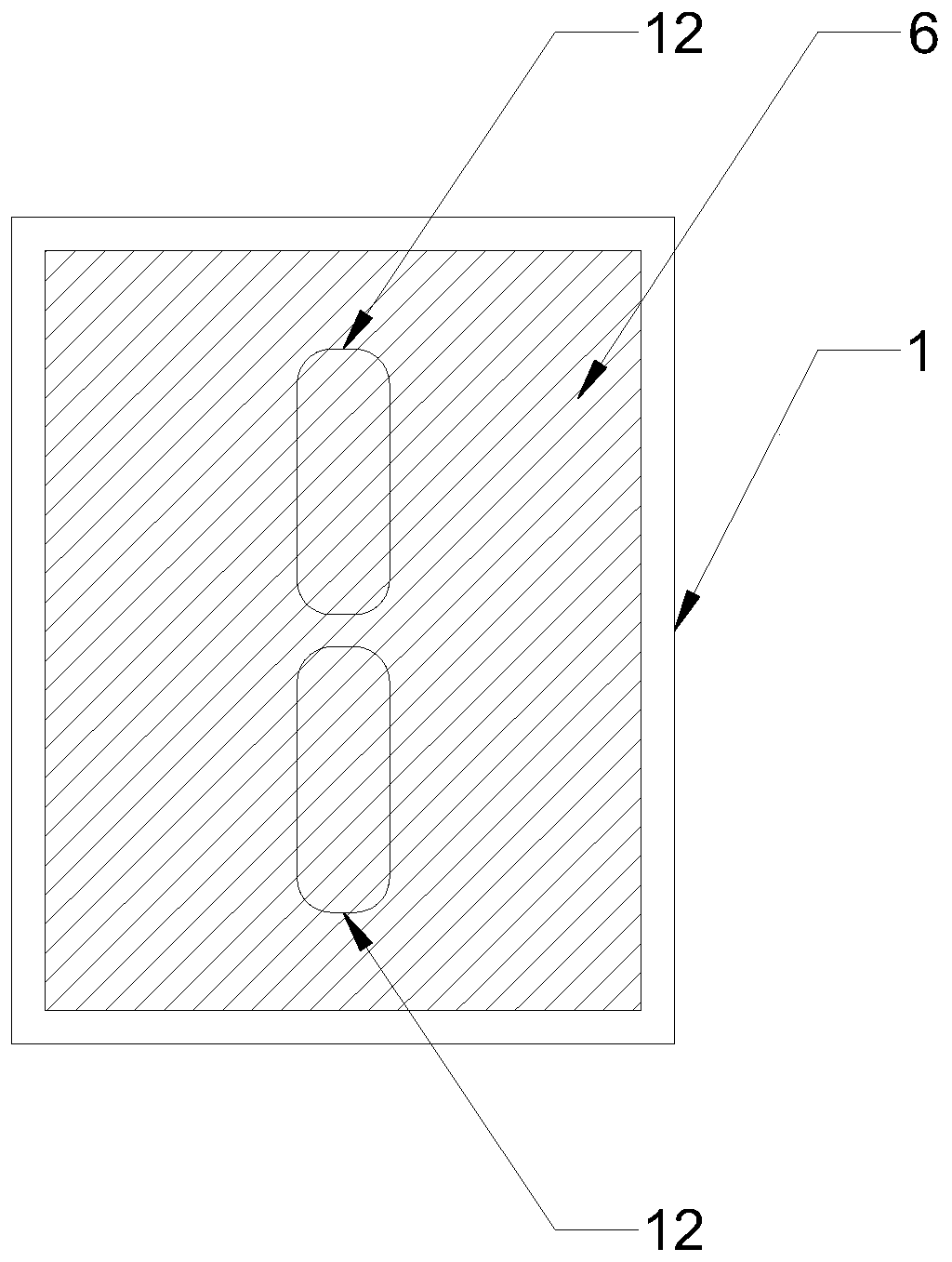

[0034] Figure 4 It is a schematic diagram of the present invention. Such as Figure 4 As shown, a processing mold for flexible pure aluminum foil and glass fiber composite material includes an corrosion mold 1 , a first aluminum block 2 and a second aluminum block 3 . The corrosion mold 1 and the first aluminum block 2 are fixed by positioning PIN4.

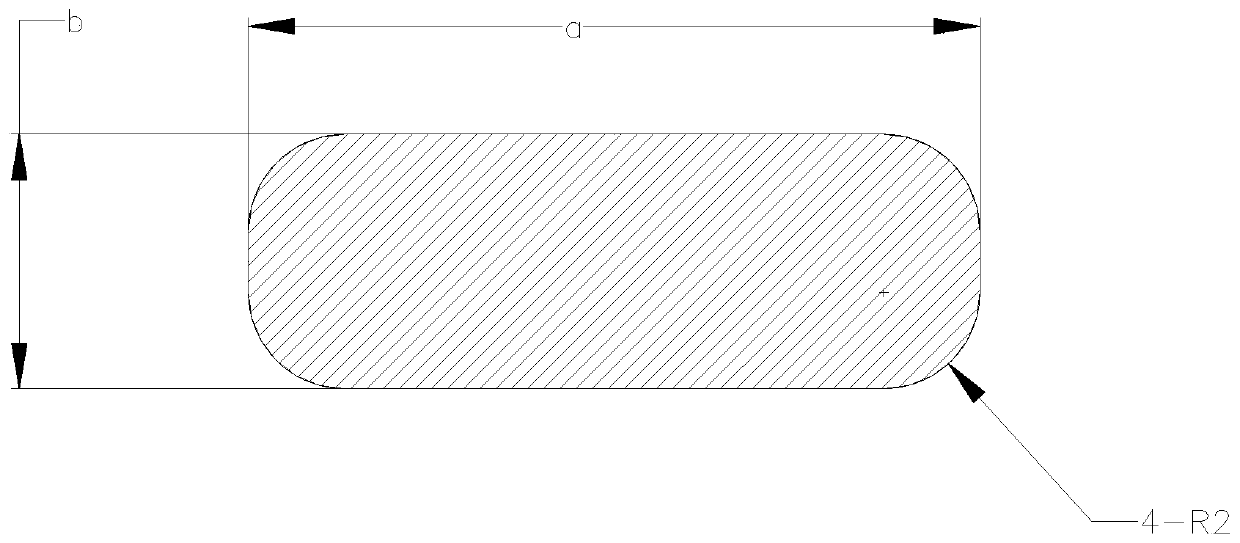

[0035] Figure 5 for Figure 4 Schematic illustration of the corrosion mold in Fig. Such as Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com