Power concentrated type internal combustion multiple unit train power supply system

A technology for power supply systems and EMUs, which is applied to transmission devices with reciprocating piston internal combustion engines, etc., can solve the problems of high noise, poor economy, and inability to meet the traction performance and resistance braking performance of EMUs, and achieve low noise pollution. High maintenance cost, satisfying the effect of traction performance and resistance braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

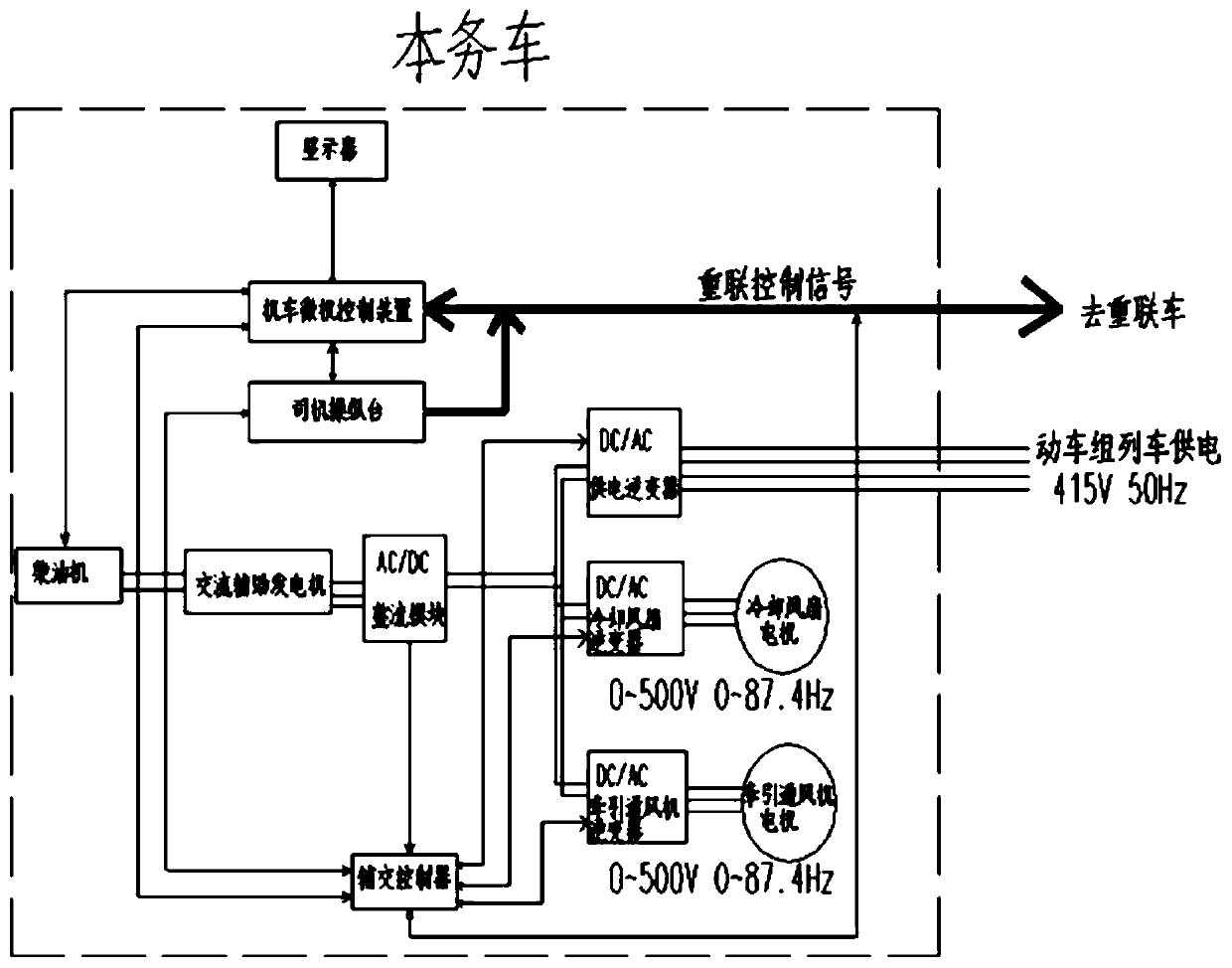

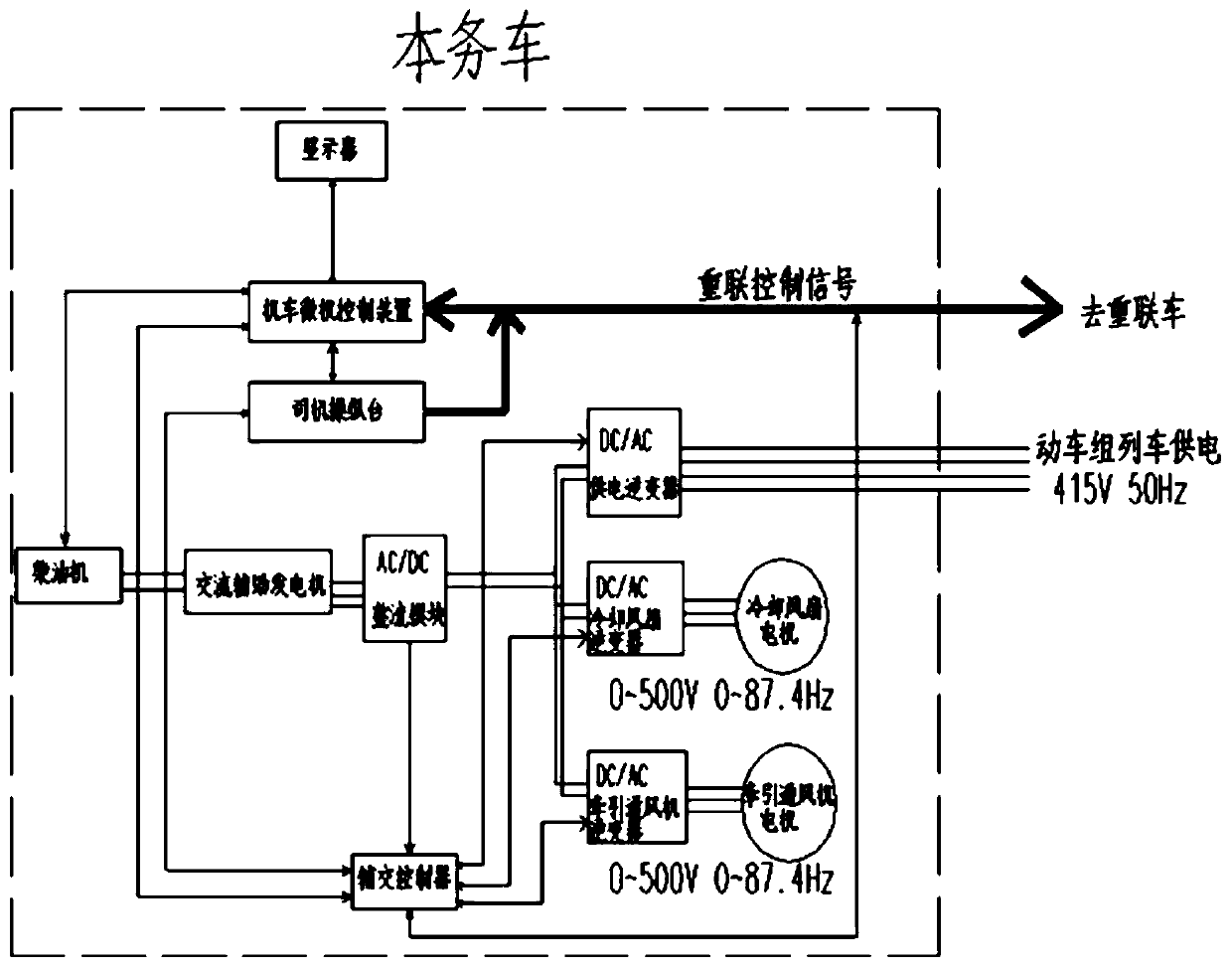

[0019] In this embodiment, a power supply system for a centralized diesel multiple unit train includes a lead car and a heavy-duty train connected to the lead car; the lead car is provided with a single-winding AC auxiliary generator, Auxiliary traffic controller, rectification module and power supply inverter for controlling the power supply of EMU trains; the AC auxiliary generator, auxiliary traffic controller and power supply inverter are respectively connected to the rectification module; the power supply inverter The auxiliary traffic controller is connected with the auxiliary traffic controller; the auxiliary traffic controller is connected with the locomotive microcomputer control device; the auxiliary traffic controller connected with the locomotive microcomputer control device is arranged in the heavy-duty train. The locomotive microcomputer control device is electrically connected with a diesel engine, and the diesel engine is in drive connection with an AC auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com