Method for extracting pure Chinese prickly ash oil from fresh Chinese prickly ash

A technology for Chinese prickly ash oil and Chinese prickly ash, which is applied in the directions of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of low extraction efficiency of prickly ash oil, low numbness of prickly ash oil, poor quality of prickly ash oil, etc. The effect of oil-water separation efficiency, improving quality and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for extracting pure Zanthoxylum bungeanum oil from fresh Zanthoxylum bungeanum of the present invention comprises the following steps:

[0034] S1. Raw material processing: wash fresh peppers after refrigeration;

[0035] S2, preparing pepper juice, including the following sub-steps:

[0036] A. Put the cleaned fresh peppers into the press machine, peel off the peel, pulp, pepper embryos and seeds of fresh peppers through the press, crush and grind the peel and pulp to become pepper juice, and pass the pepper embryos and seeds through the press discharge;

[0037] B. Store the pepper juice in a sealed pool, add water to the pepper juice according to the weight ratio of pepper juice and water 1:1-4, and then inject air evenly into the sealed pool;

[0038] C, heat the prickly ash juice at 70-80°C;

[0039] S3. Preparation of Zanthoxylum bungeanum pure oil: put the heated Zanthoxylum bungeanum juice into an oil-water separator, and obtain Zanthoxylum bungean...

Embodiment 2

[0048] Based on Example 1, the specific implementation of extracting pure Zanthoxylum bungeanum oil from fresh Zanthoxylum bungeanum of the present invention is as follows: 1. Fresh Zanthoxylum bungeanum is picked by cutting instead of harvesting, put into a special transportation frame for Zanthoxylum bungeanum, and fresh Zanthoxylum bungeanum fruit 8 is picked up by a special refrigerated transport vehicle Put it in the fresh-keeping warehouse for storage within hours, and set the temperature of the fresh-keeping warehouse between 0-5°C; 2. Put the fresh peppercorns into the automatic washing machine, clean them with clean water to remove dust and impurities, and automatically send them to non-standard customized peppercorns In the fresh fruit press machine, peel off the peel, pulp and pepper germ seeds of the fresh Zanthoxylum bungeanum through the press, the peel and pulp are crushed and refined, and become Zanthoxylum bungeanum juice, and the pepper embryos and seeds are di...

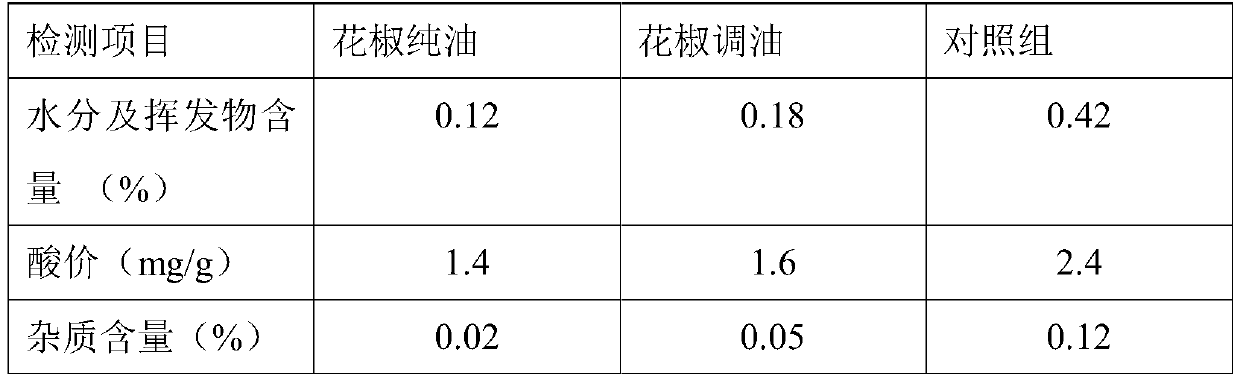

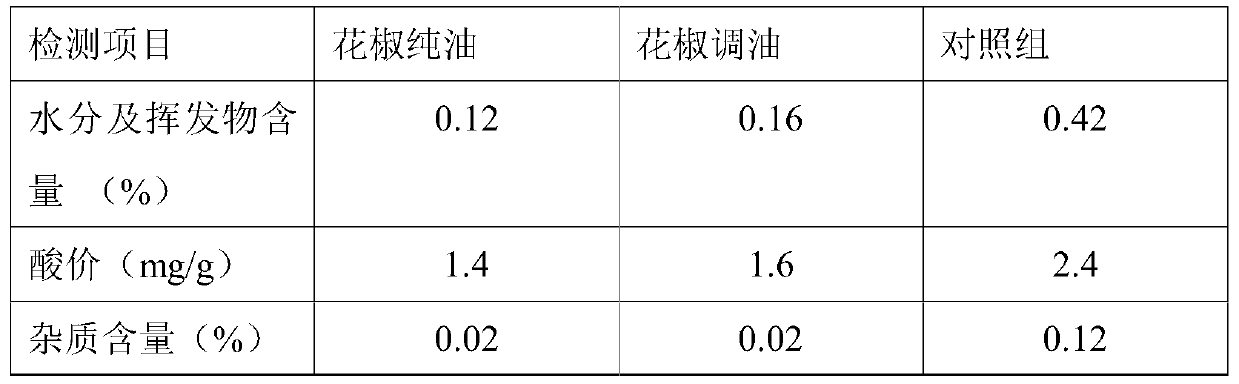

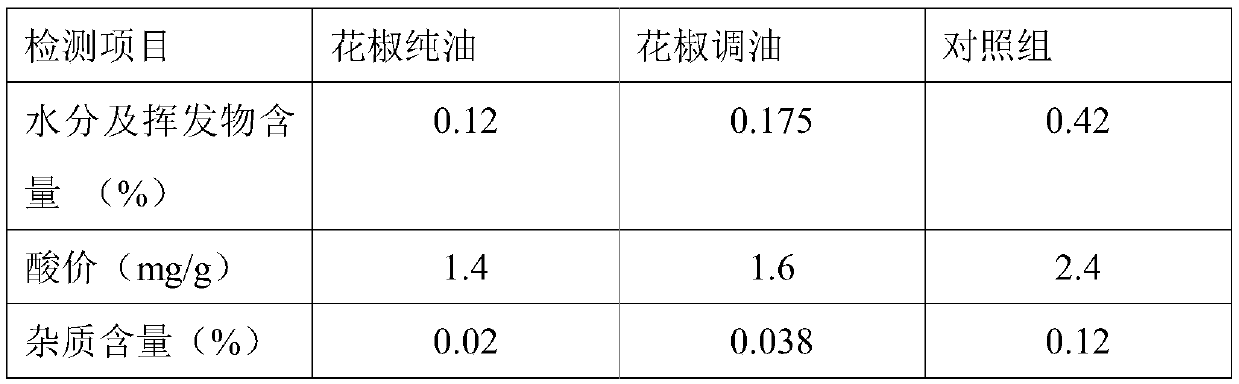

Embodiment 3

[0054] Based on the above-mentioned embodiments, the specific implementation of extracting pure Zanthoxylum bungeanum oil from fresh Zanthoxylum bungeanum of the present invention is as follows: 1. The fresh Zanthoxylum bungeanum is picked by cutting instead of harvesting, put into a special transportation frame for Zanthoxylum bungeanum, and the fresh Zanthoxylum bungeanum fruit 8 is picked up by a special refrigerated truck Put it in the fresh-keeping warehouse for storage within hours, and set the temperature of the fresh-keeping warehouse between 0-5°C; 2. Put the fresh peppercorns into the automatic washing machine, clean them with clean water to remove dust and impurities, and automatically send them to non-standard customized peppercorns In the fresh fruit press machine, peel off the peel, pulp and pepper germ seeds of the fresh Zanthoxylum bungeanum through the press, the peel and pulp are crushed and refined, and become Zanthoxylum bungeanum juice, and the pepper embryo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com