Corrosion prevention method of anchor rod assembly for wind power generator set foundation

A technology for wind turbines and bolts, which is applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve the problems of high production cost, easy to get stuck, easy to damage anti-corrosion coatings, etc., to save construction time and Construction cost, improved anti-corrosion service life, excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

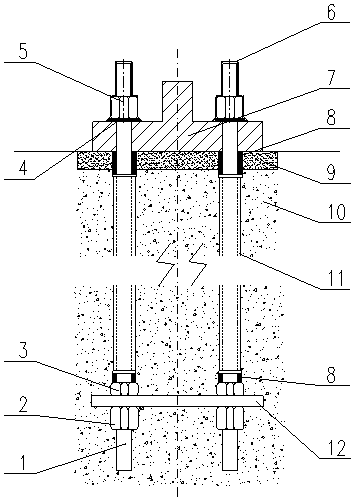

[0026] An anti-corrosion method for a bolt assembly used for the foundation of a wind power generating set, the bolt assembly includes a bolt 1, a nut I5, a nut II2, a lock nut 3 and a gasket 4, such as Figure 1-2 As shown, carry out anti-corrosion treatment according to the following steps:

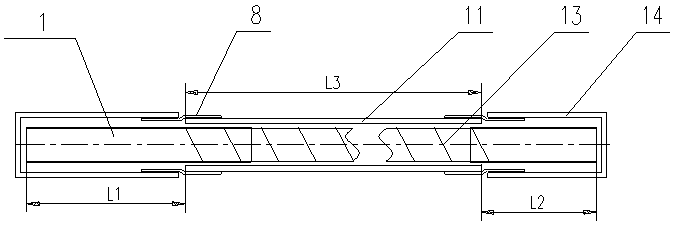

[0027] 1) Anti-corrosion treatment of the anchor rod 1: the entire length of the anchor rod 1 is coated with anti-rust grease, the middle part L3 of the anchor rod 1 located inside the wind turbine is covered with PE stretch film 13, and then the middle part covered with PE stretch film 13 L3 passes through the PE pipe 11, the two ends of the PE pipe 11 are sealed with heat shrinkable sleeves 8, and the two ends of the anchor rod 1 that are not covered by the PE stretch film 13 are provided with temporary protective caps 14;

[0028] 2) Anti-corrosion treatment of nut Ⅰ5, nut Ⅱ2, lock nut 3 and gasket 4: nut Ⅰ5 and gasket 4 adopt dacromet surface treatment, nut Ⅱ2 and lock nut 3 adopt b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com