A laser emitting and receiving device, a furnace coke loss monitoring system and method

A laser emission and detection method technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as increasing the workload of power plant operation and maintenance personnel, excess thermal power installed capacity, and affecting the safe and economical operation of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

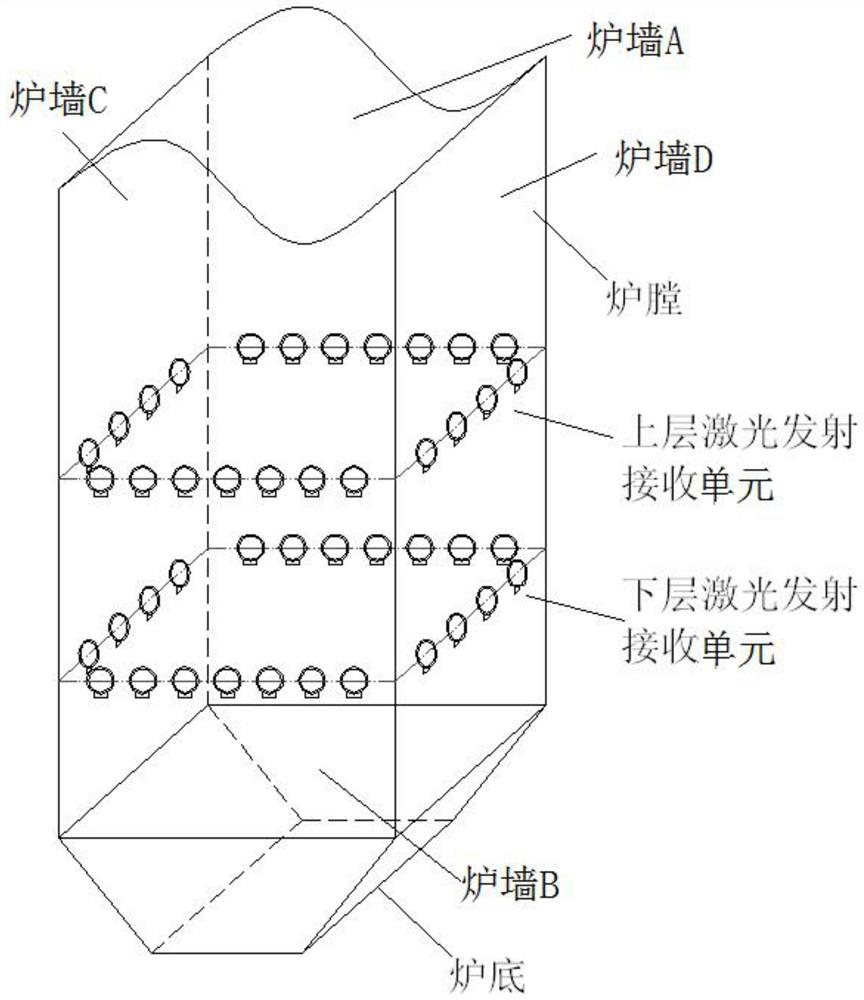

[0043] like figure 1 As shown, the laser emitting and receiving device is arranged at the bottom of the boiler, including two layers of upper laser emitting and receiving units and lower laser emitting and receiving units arranged in parallel and separated by a certain vertical distance. The upper and lower laser emitting and receiving units respectively include several Only uniformly arranged lasers, two lasers arranged on the opposite wall respectively measure the horizontal distance from the laser to the falling coke block in the boiler. The laser is arranged outside the bottom wall of the boiler, and the laser is incident through the hole arranged on the bottom wall of the boiler. The temperature at the bottom of the boiler is already low, but by setting the laser on the outside of the bottom wall of the boiler, the influence of lowering the temperature of the bottom of the boiler on the laser can be further isolated.

[0044] In this embodiment, the upper laser emitting ...

Embodiment 2

[0048] like image 3 As shown, the upper laser emitting and receiving unit includes lasers evenly arranged on furnace wall A and furnace wall B, and the lower layer laser emitting and receiving unit includes lasers evenly arranged on furnace wall C and furnace wall D; furnace wall A and furnace wall B are one A set of opposite furnace bottom walls; said furnace wall C and furnace wall D are another set of relative furnace bottom walls.

Embodiment 3

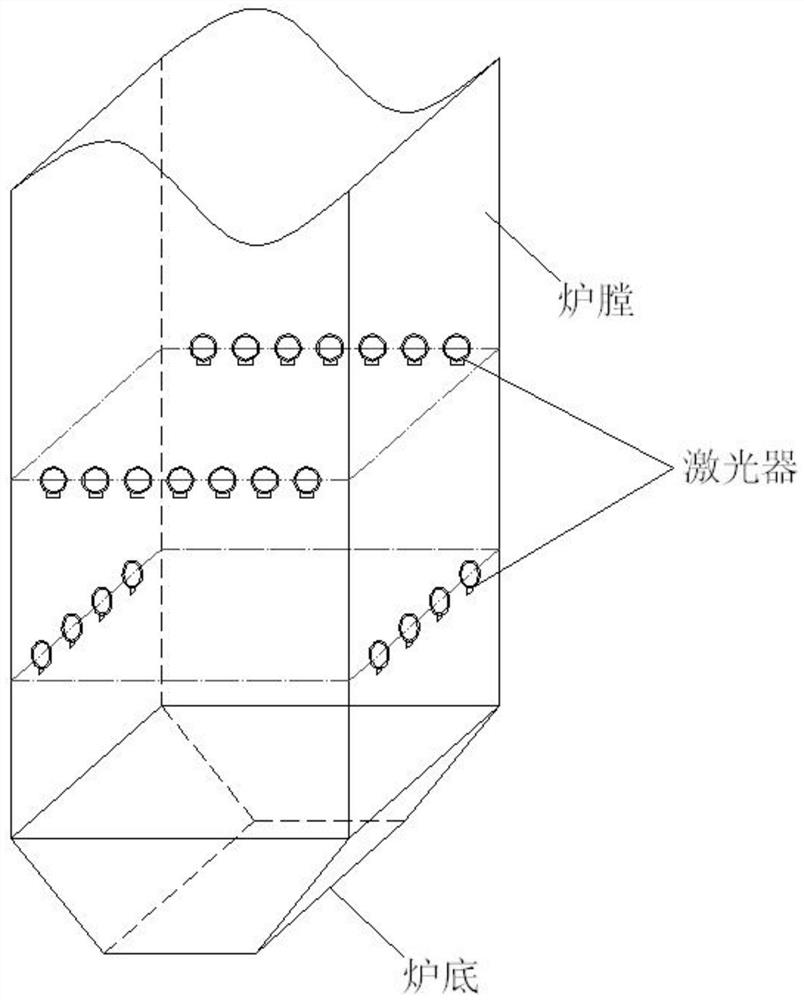

[0050] like Figure 4 As shown, the upper laser emitting and receiving unit includes lasers evenly arranged on furnace wall A and furnace wall D, and the lower laser emitting and receiving unit includes lasers evenly arranged on furnace wall B and furnace wall C; furnace wall A and furnace wall D are a A group of adjacent walls; the furnace wall B and furnace wall C are another group of adjacent walls.

[0051] like Figure 5 As shown, the coke loss monitoring system in the furnace includes a laser emitting and receiving device installed at the bottom of the boiler, a signal processing unit electrically connected to the laser emitting device, and a display terminal electrically connected to the signal processing unit.

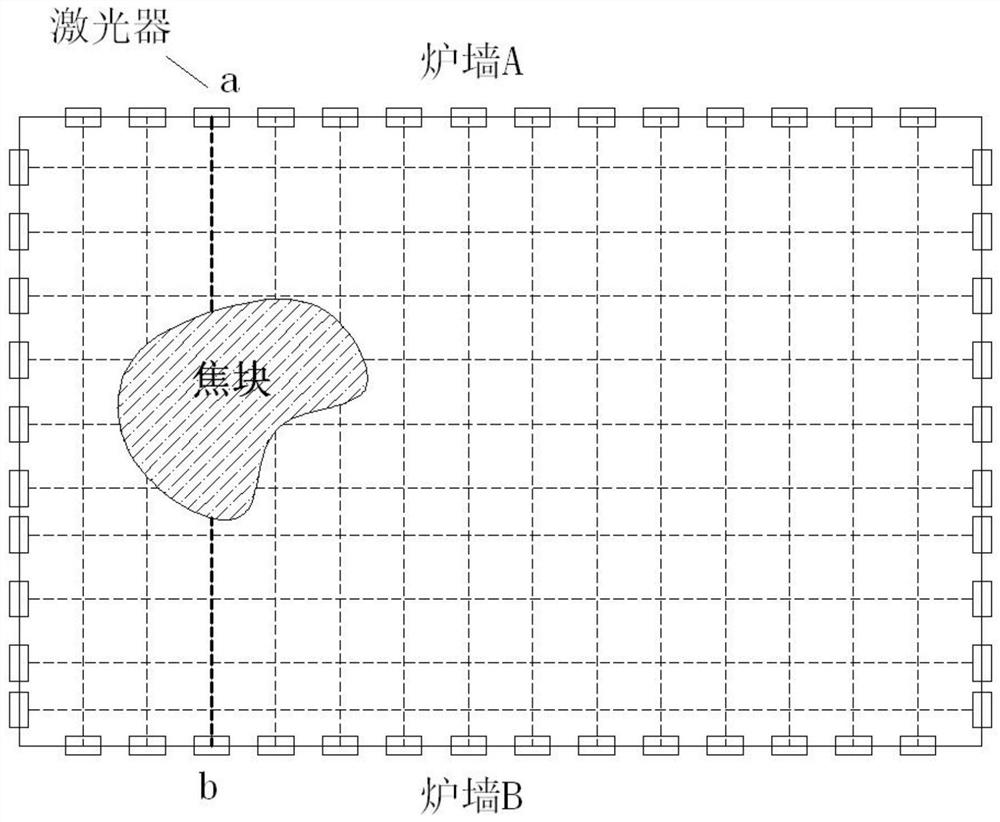

[0052] The distance between the laser transmitter and receiver determines the accuracy of the observable focal block, the smaller the arrangement interval, the smaller the observable focal block. When the coke block falls from the upper part of the furnace an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com