Monitoring method based on digital twin model and point collision machine equipment applying same

A model and equipment technology, applied in special data processing applications, electrical digital data processing, computer-aided design, etc., can solve the problems of high processing cost, complexity, and inability to synchronously monitor processing parameters, so as to reduce the scrap rate and achieve strong pertinence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] Digital twins: make full use of data such as physical models, sensor updates, and operation history, integrate multi-disciplinary, multi-physical quantities, multi-scale, and multi-probability simulation processes, and complete the mapping in the virtual space to reflect the entire life of the corresponding physical equipment Cycle process, also known as "digital mirror image", "digital twin" or "digital twin".

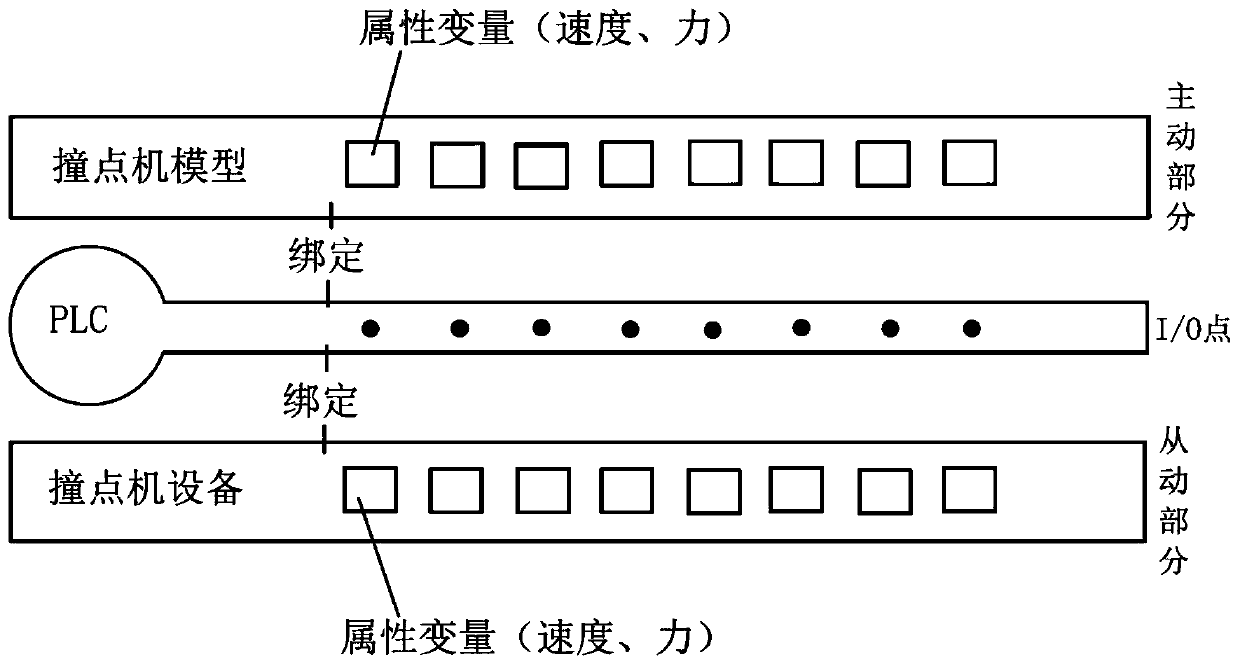

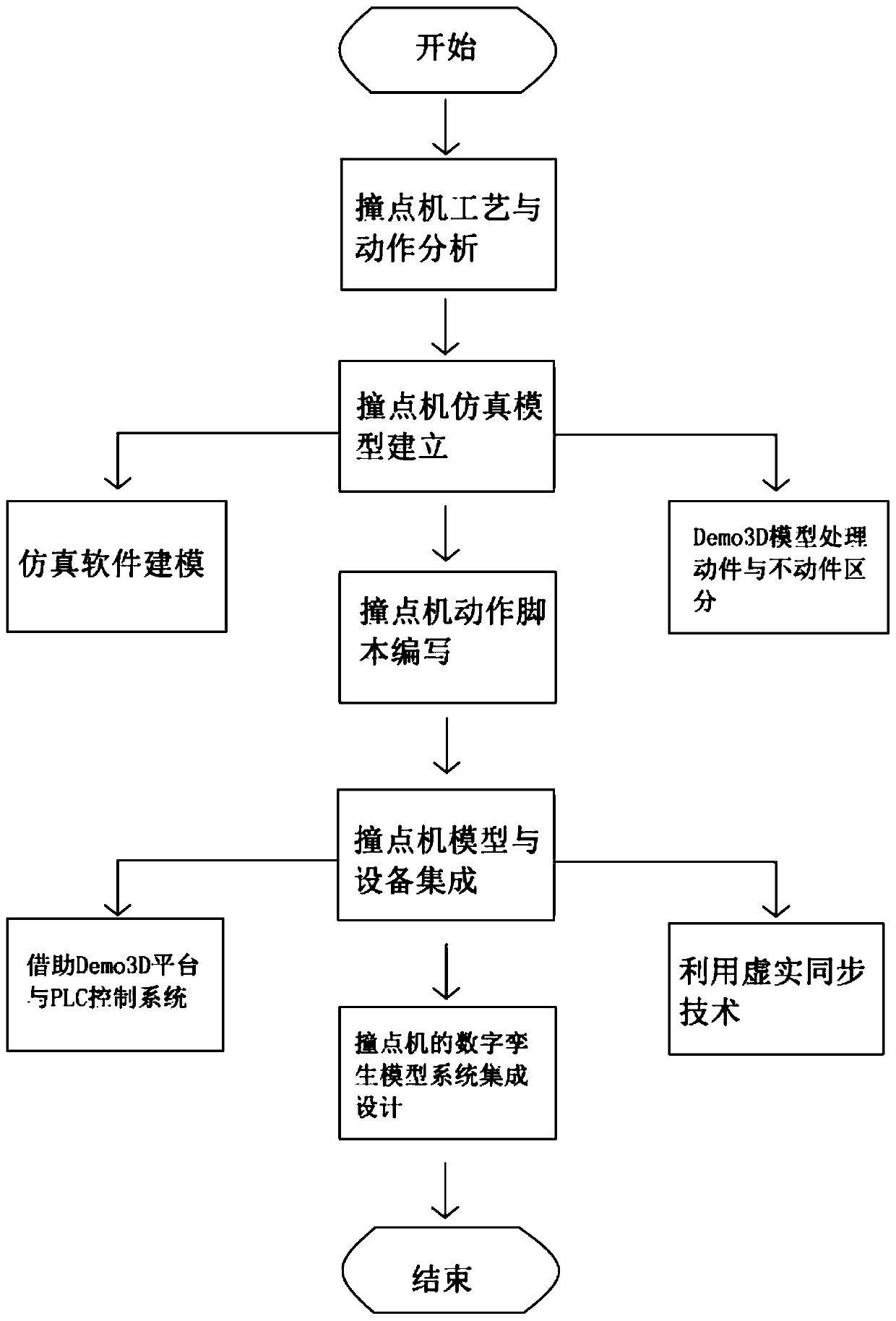

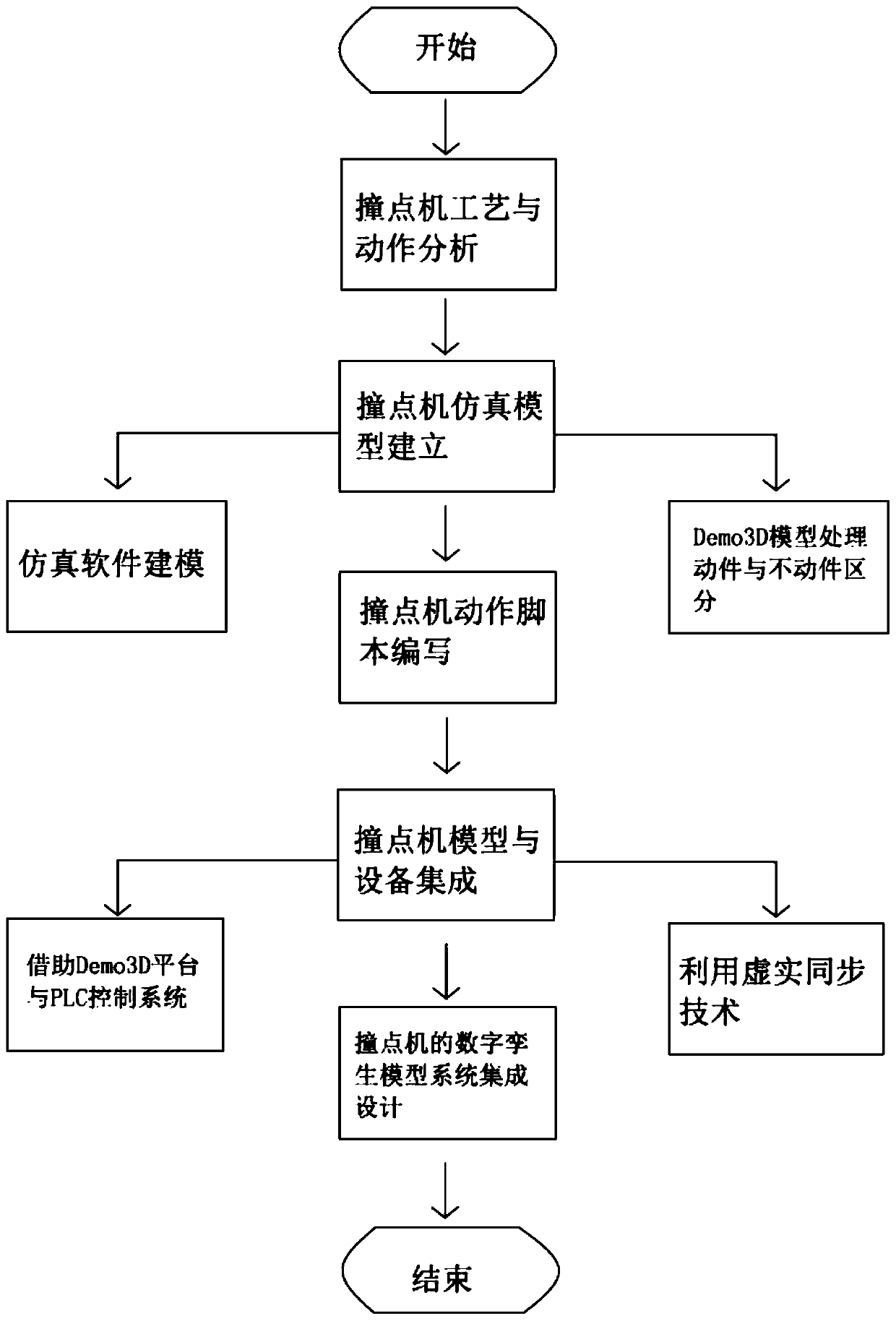

[0025] Such as figure 1 with 2 As shown, the monitoring method based on the digital twin model is applied to the processing of the impact machine equipment, which includes the following steps:

[0026] a. The simulation modeling of the impact machine equipment, first use the mechanical three-dimensional modeling platform to complete the simulation model design, and then import the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com