LED flip chip integrated packaging structure and packaging method thereof

An integrated package and chip technology, which is applied in the field of LED flip-chip integrated package structure and its package, can solve the problems of large terminal LED products, achieve the effects of reducing the packaging process, increasing luminous efficiency, and reducing the cost of packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

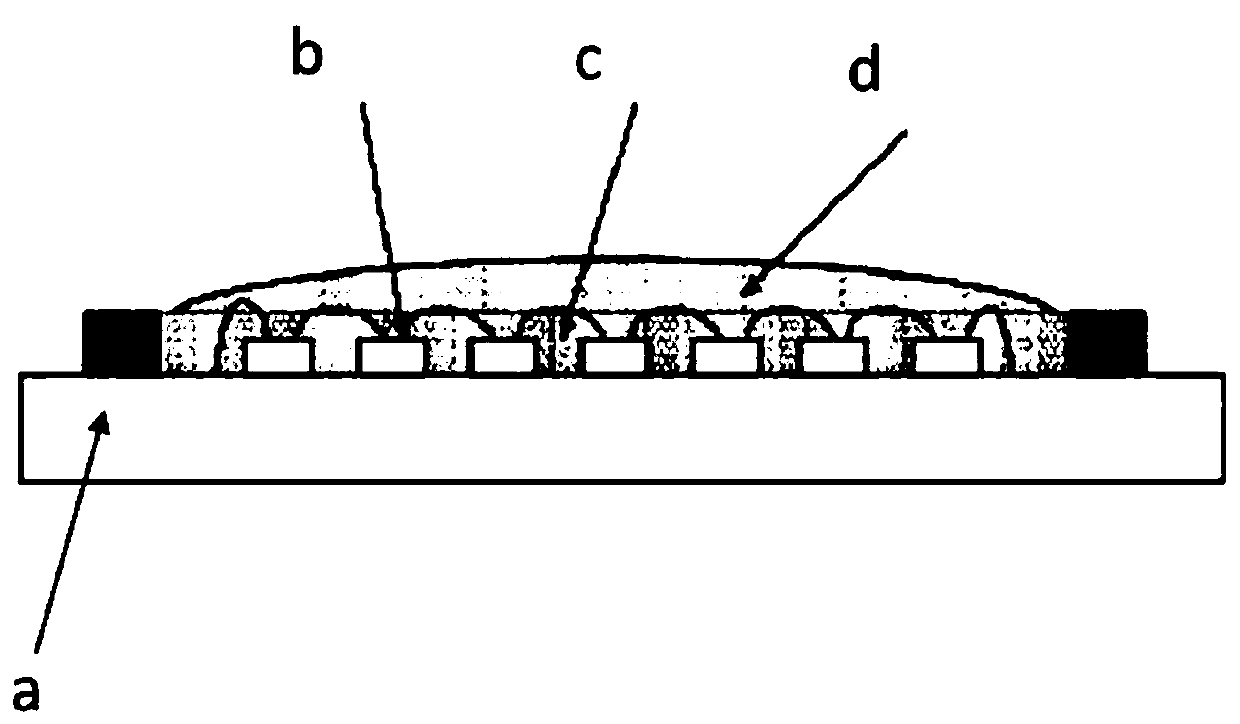

Examples

Embodiment 1

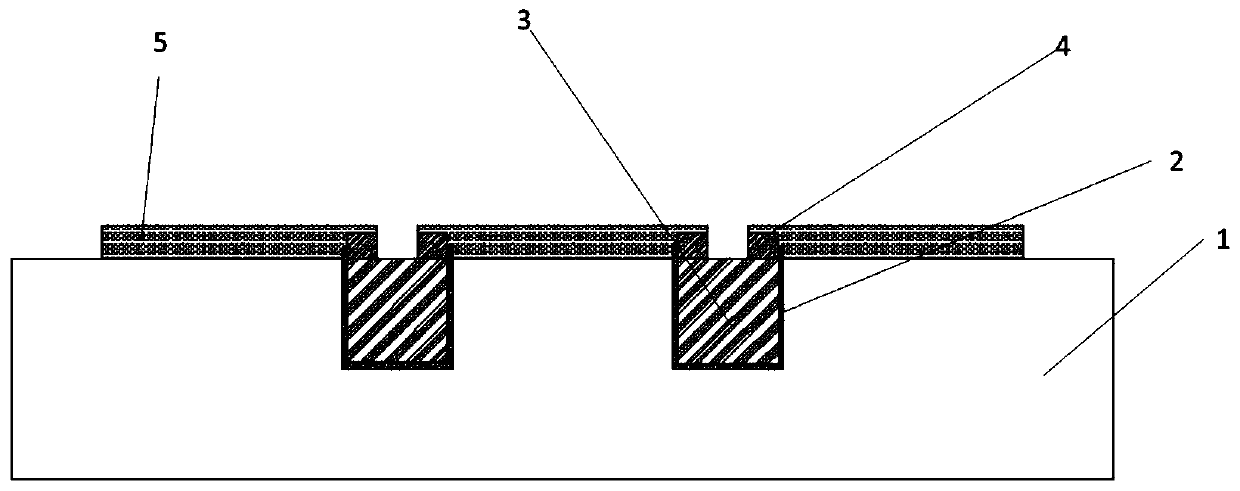

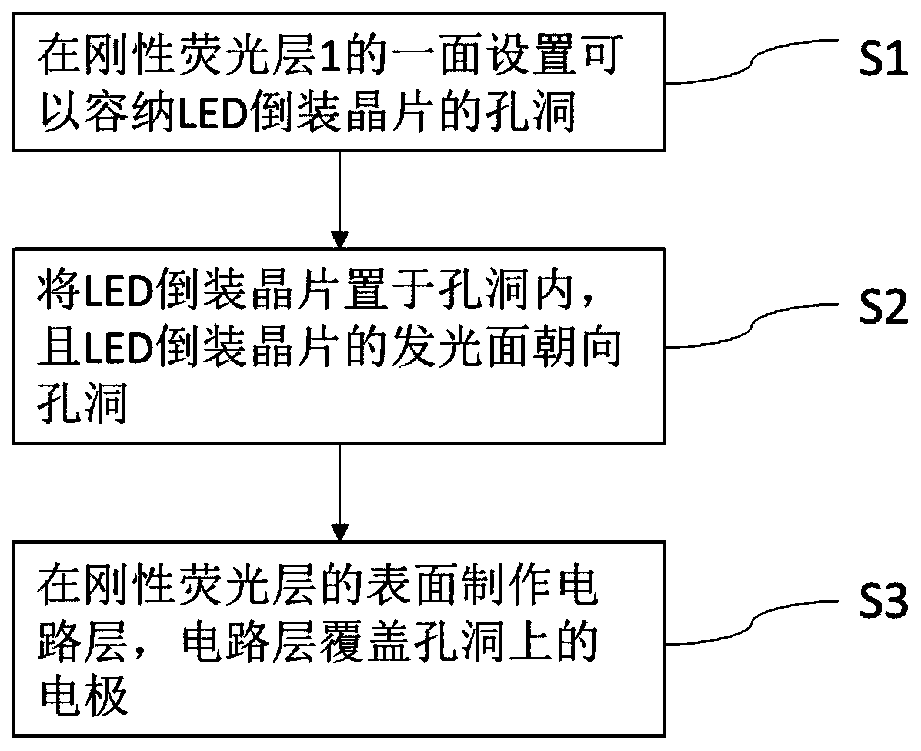

[0037] Such as figure 2 Shows the structural diagram of the LED flip-chip integrated packaging structure of the embodiment of the present invention, the LED flip-chip integrated packaging structure includes a rigid fluorescent layer 1, an LED flip-chip and a circuit layer 5, wherein the rigid fluorescent layer 1 is used as a packaging material, The packaging material is a material with high refractive index and light transmittance, such as ceramic fluorescent sheet, glass fluorescent sheet, single crystal silicon fluorescent sheet, etc., wherein the LED flip chip includes a light emitter 3 and an electrode 4, and the electrode 4 emits light The back of body 3.

[0038] Specifically, one side of the rigid phosphor layer 1 is provided with a hole for accommodating LED flip chip, the illuminant 3 is placed in the hole of the rigid phosphor layer 1, and the circuit layer 5 is arranged on the surface of the rigid phosphor layer 1 and covers the holes on the hole. The electrode an...

Embodiment 2

[0054] The embodiment of the present invention also provides an LED flip-chip integrated packaging structure, the principle is the same as the above-mentioned embodiment, the difference is that the circuit layer 5 is replaced by a reflective layer, and the reflective layer completely covers the rigid fluorescent layer 1 with a On one side of the hole (electrode 4 is not covered), the reflective layer is not connected to the electrode of the LED flip chip, and the electrode of the LED flip chip is connected to the driving circuit outside the integrated package structure. The luminous efficiency of the LED product can be better increased through the reflective layer .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com