Efficient industrial dust removal device

A kind of dust removal equipment and industrial technology, applied in the field of high-efficiency industrial dust removal equipment, can solve the problems of poor effect of harmful gas and incomplete dust removal, etc., and achieve the effect of novel design, reduced operation burden and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

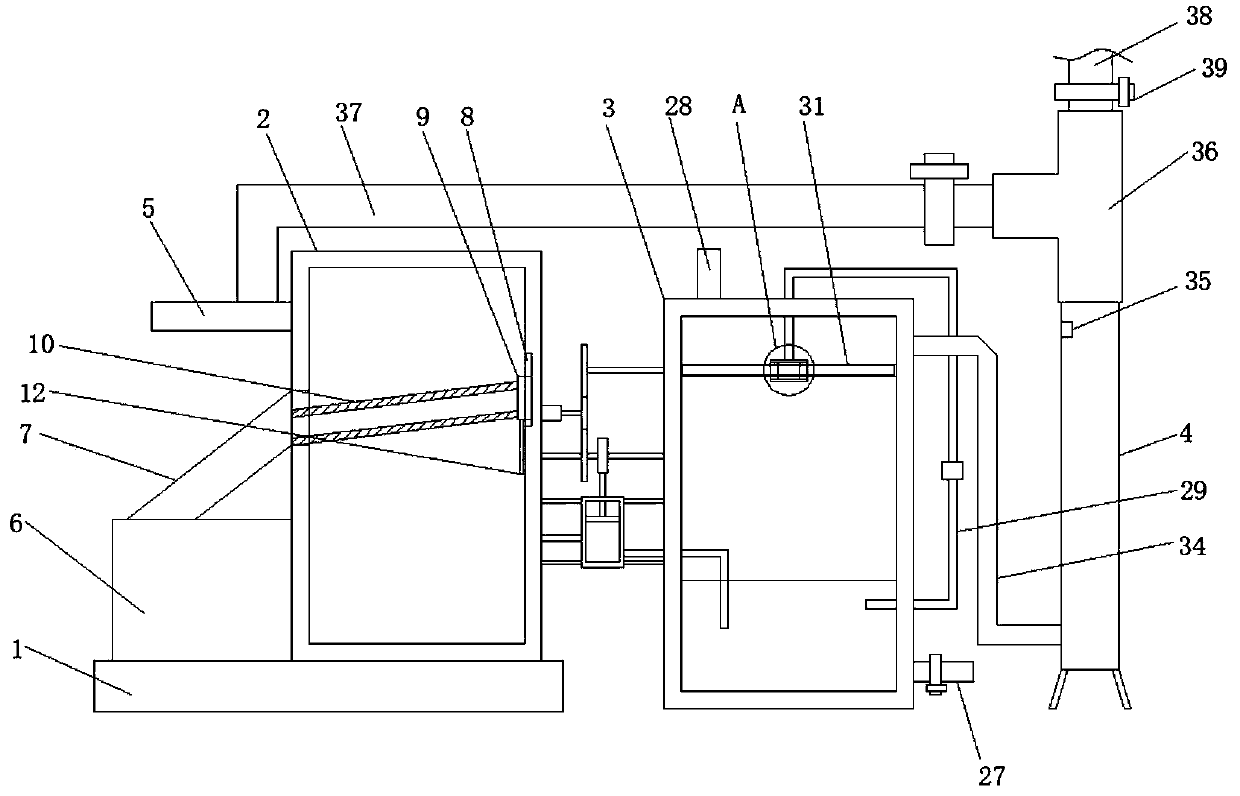

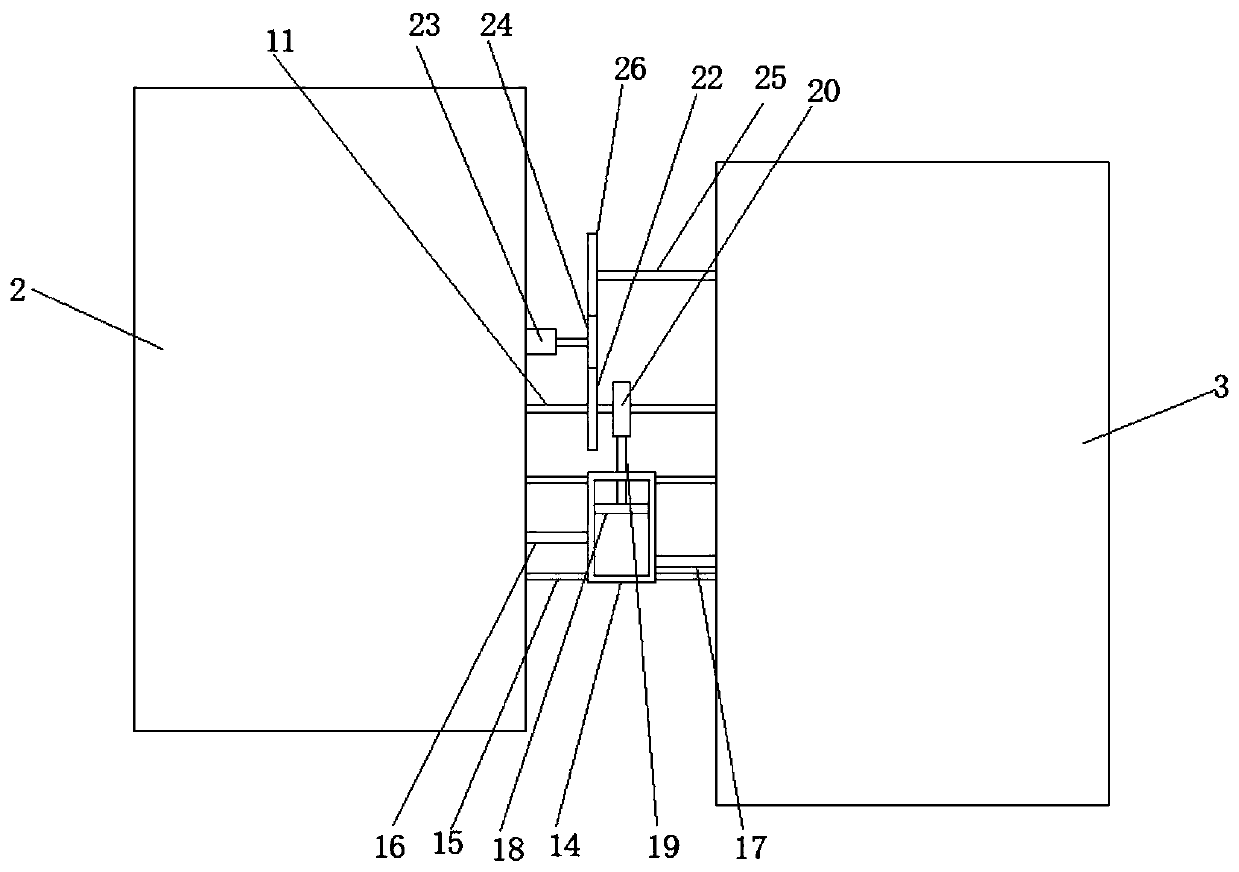

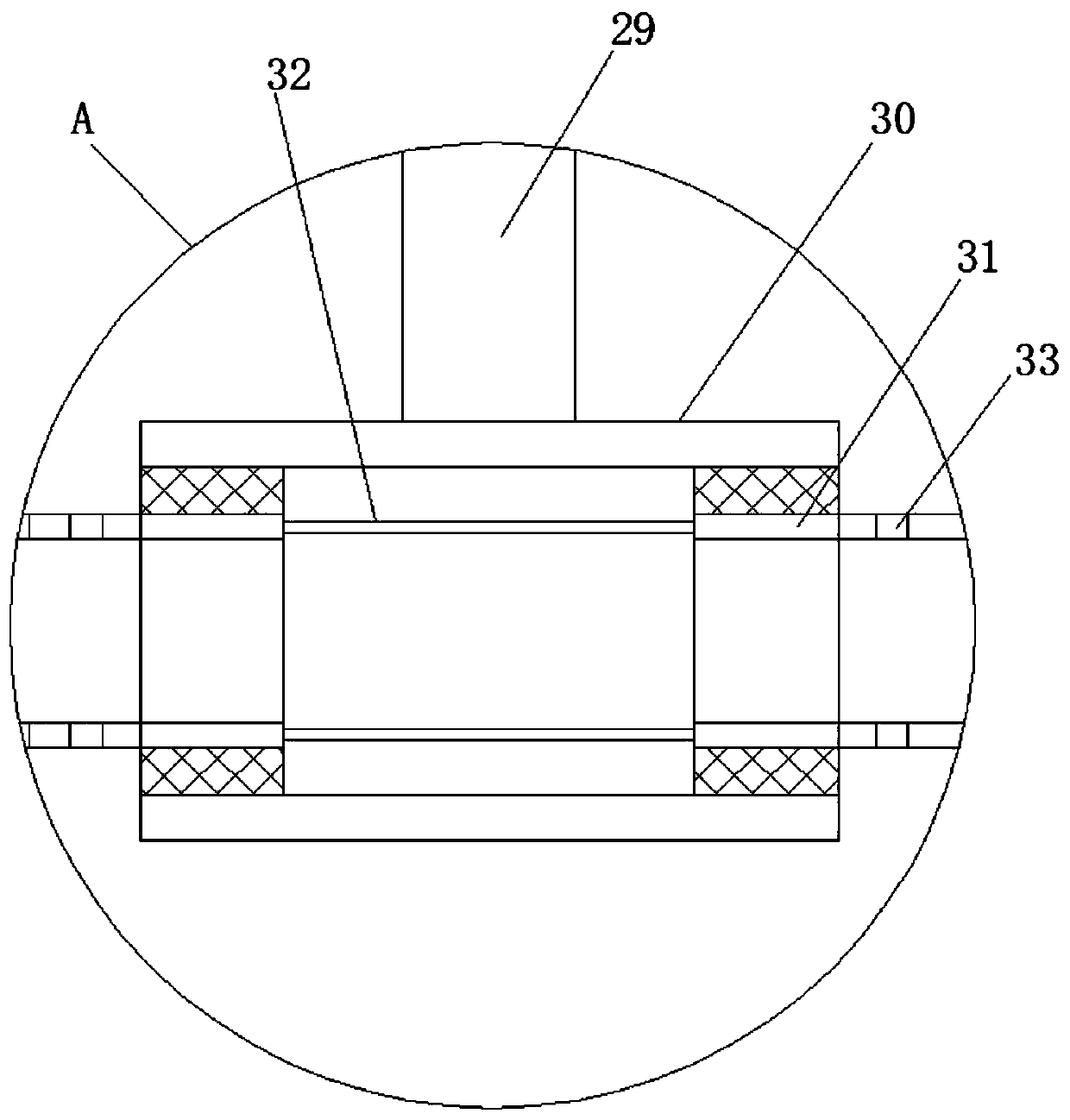

[0024] Embodiment: During operation, the industrial exhaust gas is passed into the dust suction pipe 5, and the motor 23 is turned on to drive the second gear 24 to rotate. When the second gear 24 rotates, it drives the first gear 22 and the third gear 26 to rotate, so that the first rotating shaft 11 and the second rotating shaft 25 rotation, when the rotating shaft 11 rotates, it drives the cam 12 and the sector gear 13 to rotate, the cam 12 makes the filter screen 10 vibrate, the dust filtered by the filter screen 10 is shaken off, and enters the collection box 6 through the ash outlet pipe 7 , the sector gear 13 rotates to make the movable frame 20 move up and down, thereby driving the piston block 18 to move in the compressed air box 14 through the movable rod 19, and the gas in the dust collection box 2 is delivered to the desulfurization box 3, and the gas in the air inlet pipe 16 and the air outlet pipe Check valves are installed on 17 to prevent gas backflow. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com