Preparation of Nickel Cobaltate/Bismuth Oxychloride Nanocomposite and Its Application in Catalytic Reduction of Organic Compounds

A technology of bismuth oxychloride nanometer and composite material, which is applied in physical/chemical process catalyst, chemical/physical process, reduced water/sewage treatment, etc., can solve the problem of low efficiency and change of catalytic reduction 4-nitrophenol and organic dyes. Catalytic activity, influence and other issues, to achieve the effect of high catalytic reduction efficiency and improved catalytic reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

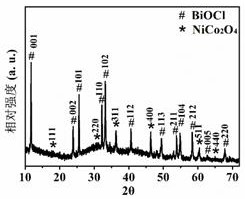

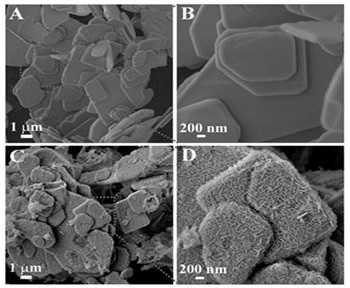

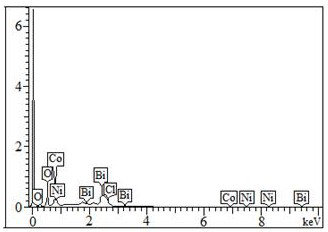

[0026] 0.9701g Bi(NO 3 ) 3 ·5H 2 O dissolved in 20 mL of HNO 3 to obtain the first solution; dissolve 0.1491g KCl in 10mL distilled water to obtain the KCl solution; under magnetic stirring, add the KCl solution dropwise to the first solution; In the lining (the lining is sealed with a stainless steel autoclave), react at a temperature of 160°C for 24h, cool to room temperature, and centrifuge to obtain the first precipitate, which is washed three times with distilled water and ethanol, and dried at a temperature of 60°C for 8h , to obtain BiOCl nanosheets; disperse 50mg of BiOCl in 50mL of distilled water and ultrasonically 2h to obtain a BiOCl dispersion; 14.65mg of Ni(NO 3 ) 2 ·6H 2 O and 29.33mg of Co(NO 3 ) 2 ·6H 2 O was dissolved in 13.34 mL of distilled water to form a second solution, and the concentration of metal ions in this second solution per liter was 11.35 mmol / L. 64.54 mg of hexamethylenetetramine was dissolved in distilled water to form a third soluti...

Embodiment 2

[0043] According to 10mL of HNO with a molar volume concentration of 1mol / L 3 Add 1mmol Bi(NO 3 ) 3 ·5H 2 The proportion of O, the Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 According to the proportion of adding 1mmol KCl in 5mL distilled water, KCl was dissolved in distilled water to obtain a KCl solution; according to the volume ratio of 1:1, the KCl solution and the first solution were respectively taken under the condition of magnetic stirring , add the KCl solution dropwise to the first solution, after the dropwise addition, keep stirring for 30 min, transfer to the reaction kettle, react at a temperature of 150°C for 25h, cool to normal temperature, and centrifuge to obtain the first precipitate, Wash the first precipitate 3 times with distilled water and ethanol respectively; dry at 80°C for 10 h to obtain BiOCl nanosheets; In the process, ultrasound 1.5h, to get BiOCl dispersion; according to the molar ratio of 1:2.5, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 ...

Embodiment 3

[0045] According to 10mL of HNO with a molar volume concentration of 1mol / L 3 Add 1mmol Bi(NO 3 ) 3 ·5H 2 The proportion of O, the Bi(NO 3 ) 3 ·5H 2 O dissolved in HNO 3 According to the proportion of adding 1mmol KCl in 5mL of distilled water, KCl was dissolved in distilled water to obtain a KCl solution; according to the volume ratio of 1:2, the KCl solution and the first solution were respectively taken under the condition of magnetic stirring , add the KCl solution dropwise to the first solution, after the dropwise addition, keep stirring for 30 min, transfer to the reaction kettle, react at 160°C for 23h, cool to normal temperature, and centrifuge to obtain the first precipitate, Wash the first precipitate 3 times with distilled water and ethanol respectively; dry at 60°C for 8 hours to obtain BiOCl nanosheets; , and ultrasonically for 2 h, the BiOCl dispersion was obtained; Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com