Mechanical carrying device based on three-degree-of-freedom parallel industrial mechanical arm

An industrial manipulator and mechanical handling technology, which is applied in the field of manipulators, can solve the problems of heavy load, limited load bearing, damage and other problems of motor parts, and achieve the effect of large transmission ratio, high motion accuracy and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment, the present invention is further described.

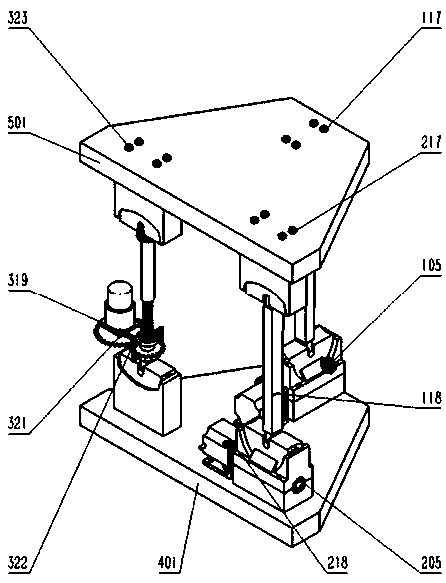

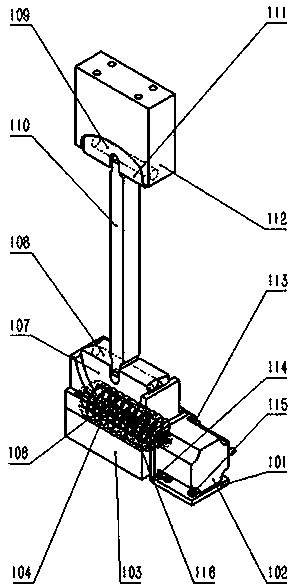

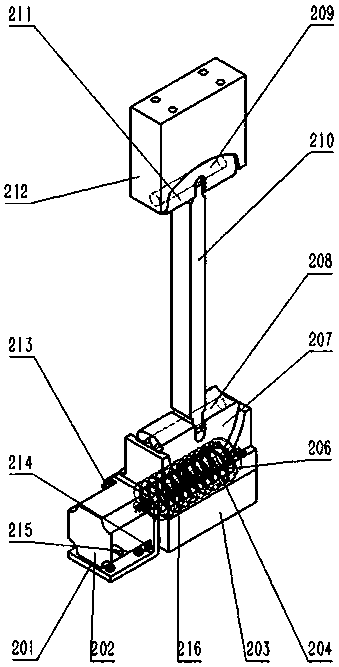

[0034] see Figure 1-Figure 4It can be seen that a mechanical handling device based on a 3-DOF parallel industrial manipulator of the present invention is composed of three parts: a fixed base 401, an intermediate transmission mechanism, and an end effector 501; and the intermediate transmission mechanism is installed on the fixed base and the end effector. Between the devices 501 , the intermediate transmission mechanism is composed of a first branch 1 , a second branch 2 , and a third branch 3 . The fixing base 401 is connected with the first motor fixing frame 101 and the first lower support base 103 in the first branch chain 1 through the first screw 115 and the third screw 117; The second motor fixing frame 201 and the second lower support base 203 in the two branch chains 2 are connected; the eighth screws 322 are connected with the third roller support frame 301 in the third bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com