Glutamic acid-based ionic liquid-type lubricant and synthesis method thereof

An ionic liquid and glutamic acid-based technology, applied in lubricating compositions, preparation of amino compounds from amines, chemical instruments and methods, etc., can solve the problems of waste oil products such as heavy pollution and difficult natural degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

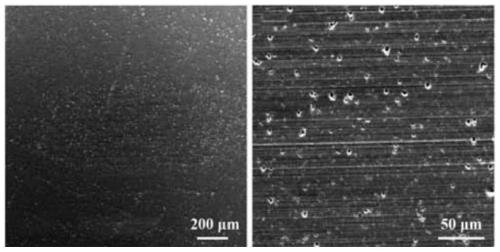

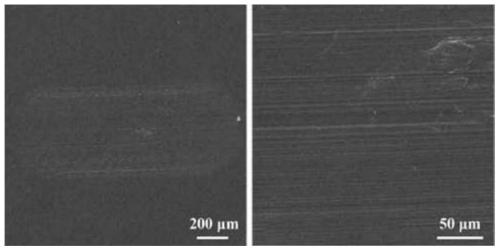

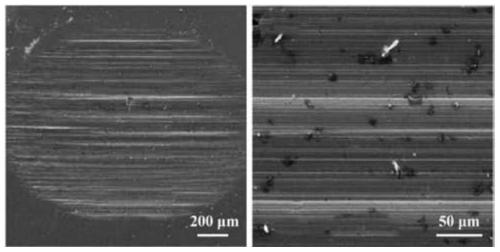

Image

Examples

Embodiment 1

[0034] 1. Get DL-glutamic acid 140g (analytical pure, 98%, commercially available) and triethylamine 101g (analytical pure, 98%, commercially available), pour into the same Erlenmeyer flask, set the magnetic stirring speed to 60r / min, stirred at room temperature (25°C) for 24h.

[0035] ②. Take 26 g of anhydrous sodium sulfate (premium grade, 99.5%, commercially available), place it in a ceramic crucible, place it in a muffle furnace and heat at 400° C. for 3 hours.

[0036] ③. Pour the anhydrous sodium sulfate obtained in step ② into the product obtained in step ①, fully stir for 3 minutes, pour out the supernatant and filter.

[0037] ④. Place the product obtained in step ③ in a rotary evaporator, and rotate it for 4 hours at 60° C., and adjust the rotation speed to 45 r / min.

[0038] ⑤. Put the product obtained in step ④ into a vacuum drying oven, and dry it at 100° C. and -0.07 MPa for 12 hours to obtain the product.

[0039] The resulting product was a pale yellow visc...

Embodiment 2

[0047] ①. Take 135g of DL-glutamic acid (analytical pure, 98%, commercially available) and 100g of DL-glutamic acid (analytical pure, 98%, commercially available), pour them into the same Erlenmeyer flask, set magnetic stirring Speed 60r / min, stir at room temperature (25°C) for 26h.

[0048] ②. Take 25 g of anhydrous sodium sulfate (premium grade, 99.5%, commercially available), place it in a ceramic crucible, place it in a muffle furnace and heat at 400° C. for 3 hours.

[0049] ③. Pour the anhydrous sodium sulfate obtained in step ② into the product obtained in step ①, fully stir for 3 minutes, pour out the supernatant and filter.

[0050] ④. Place the product obtained in step ③ in a rotary evaporator, and conduct rotary evaporation at 62° C. for 5 hours, and adjust the rotation speed to 50 r / min.

[0051] ⑤. Put the product obtained in step ④ into a vacuum drying oven, and dry it at 110° C. and -0.08 MPa for 16 hours to obtain the product.

[0052] The product obtained ...

Embodiment 3

[0060] Others are the same as embodiment 1, the difference is;

[0061] 1. Get DL-glutamic acid 140g (analytical pure, 98%, commercially available) and triethylamine 102g (analytical pure, 98%, commercially available), pour in the same Erlenmeyer flask, set magnetic stirring speed 60r / min, stirred at 35°C for 32h.

[0062] ②. Take 20 g of anhydrous sodium sulfate (premium grade, 99.5%, commercially available), place it in a ceramic crucible, place it in a muffle furnace and heat at 360° C. for 4 hours.

[0063] ③. Pour the anhydrous sodium sulfate obtained in step ② into the product obtained in step ①, fully stir for 5 minutes, pour out the supernatant and filter.

[0064] ④. Place the product obtained in step ③ in a rotary evaporator, and rotate it for 3 hours at 65° C., and adjust the rotation speed to 45 r / min.

[0065] ⑤. Put the product obtained in step ④ into a vacuum drying oven, and dry it at 120° C. and -0.06 MPa for 24 hours to obtain the product.

[0066] The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com