H-shaped steel and construction method of building with H-shaped steel structure

A technology of H-shaped steel and steel plate, which is applied in building structure, processing of building materials, construction, etc., can solve the problems of easy cracking and deformation of walls and ceilings, difficult connection of corrugated steel plates, and low connection strength of steel structures, etc. Easy to deform and crack, increase connection stability, and have good connection and fixation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

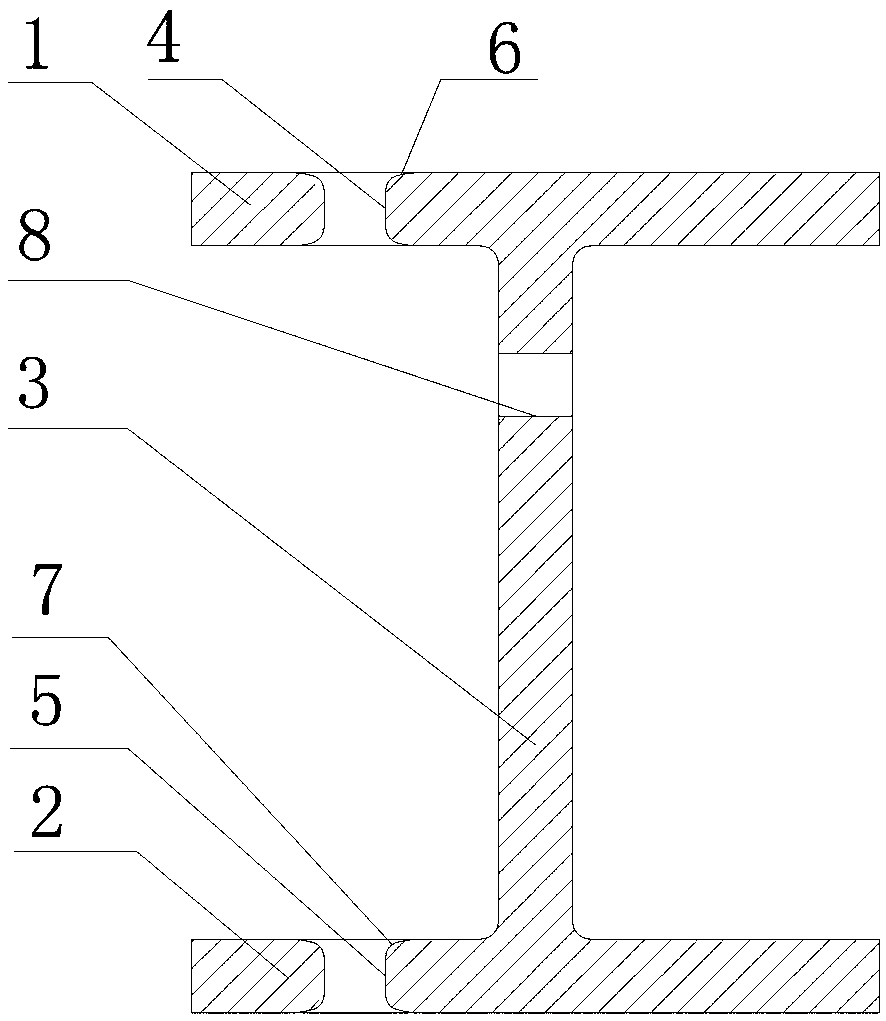

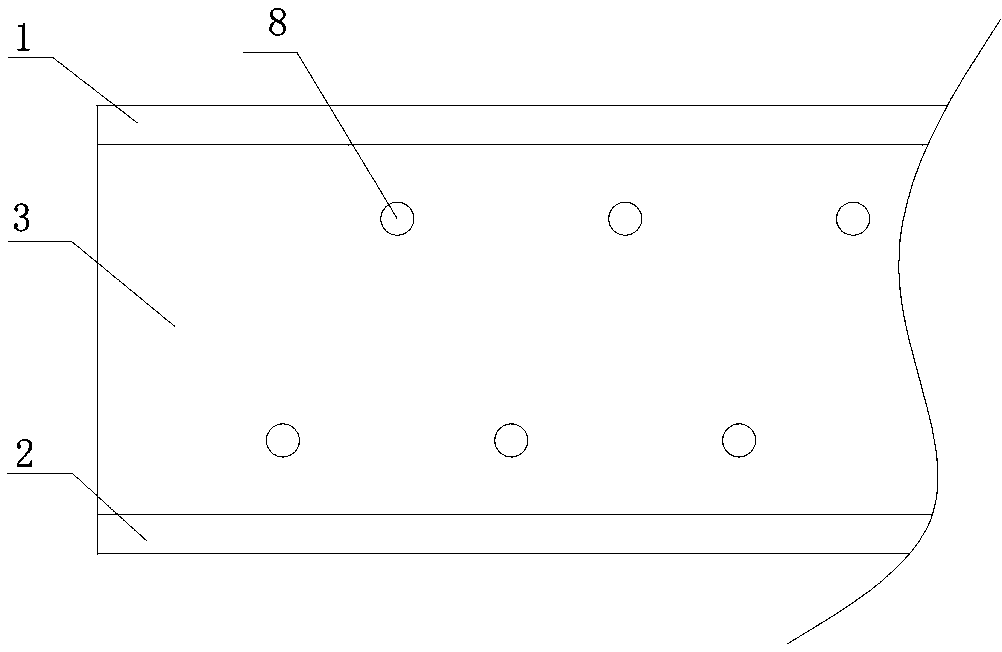

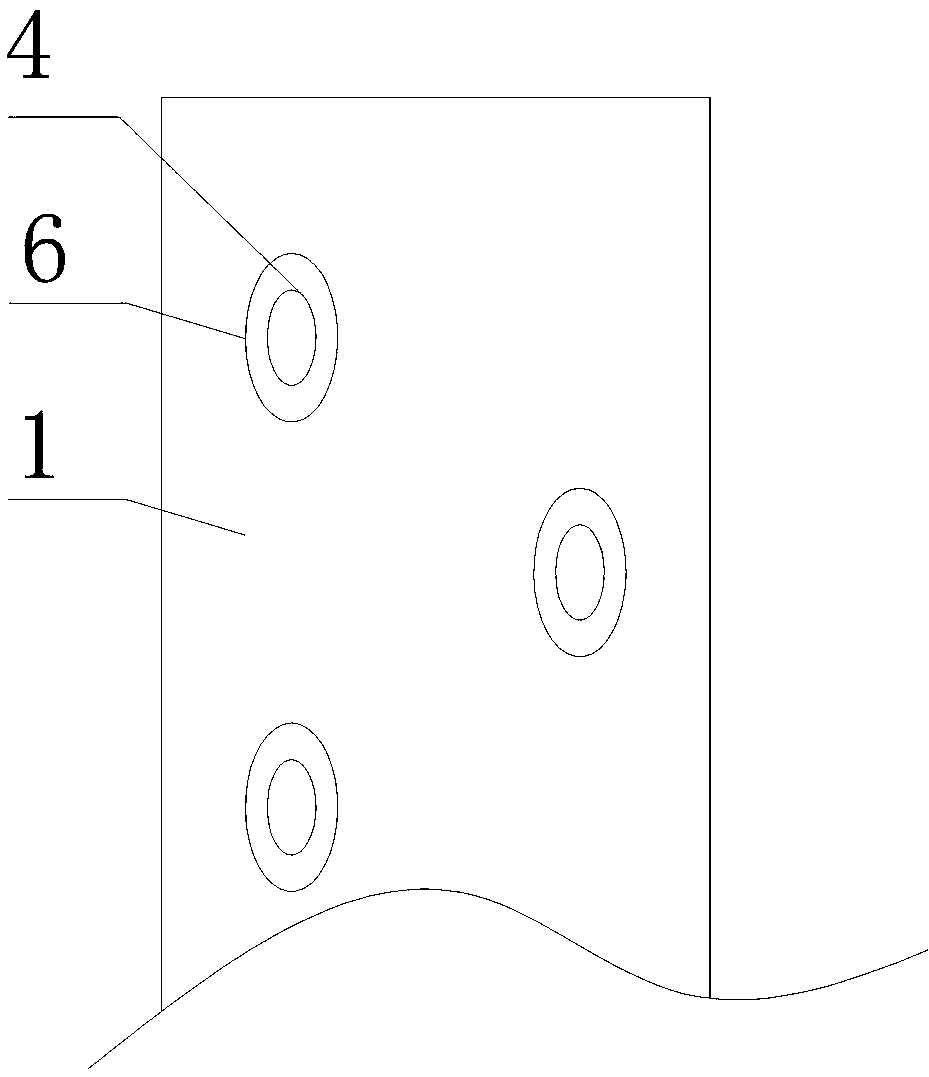

[0038] Example 1, such as Figure 1 to Figure 9 As shown, a kind of H-shaped steel includes an upper wing plate 1, a lower wing plate 2 and a web 3. The upper wing plate 1 and the lower wing plate 2 are horizontal rectangular plates corresponding to each other. The web 3 is a rectangular plate body vertically connecting the center of the lower surface of the upper wing plate 1 and the center of the upper surface of the lower wing plate 2, the upper wing plate 1 is provided with a plurality of first pouring holes 4, the first pouring holes 4 is an elliptical through hole, and a plurality of first pouring holes 4 are staggeredly distributed on the upper wing plate 1 near the left and right sides, and the major axis of the oval cross-section of the first pouring holes 4 is parallel to the On the side, the upper and lower end surfaces of the first pouring hole 4 are respectively provided with a first thinning zone 6 sunken inward, and the first thinning zone 6 is an elliptical con...

Embodiment 2

[0056] Embodiment 2 is basically the same structure as Embodiment 1, the differences, such as Figure 10 As shown, the corrugated steel plate 90 is a continuous "︺"-shaped steel plate. The advantage of this structure is that the continuous "︺"-shaped steel plate is not easily deformed, has better strength and better seismic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com