A thermal power plant waste heat furnace heat conduction pipe to prevent temperature overflow structure

A technology for thermal power plants and waste heat furnaces, applied to boiler smoke tubes/fire tubes, steam boilers, lighting and heating equipment, etc., can solve the problems of reducing waste heat energy utilization, waste heat energy loss of waste heat furnaces, energy waste, etc., to reduce Waste heat overflow, prevent overflow, improve the effect of heat preservation and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

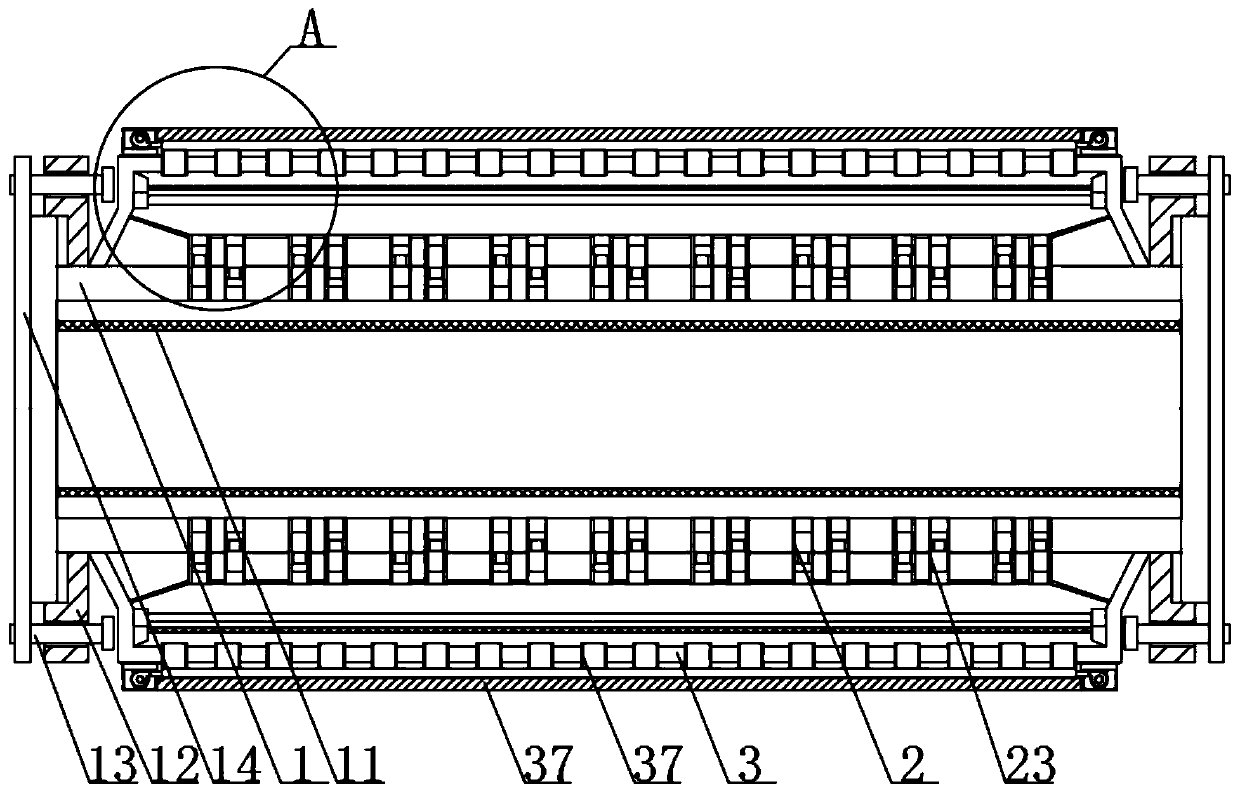

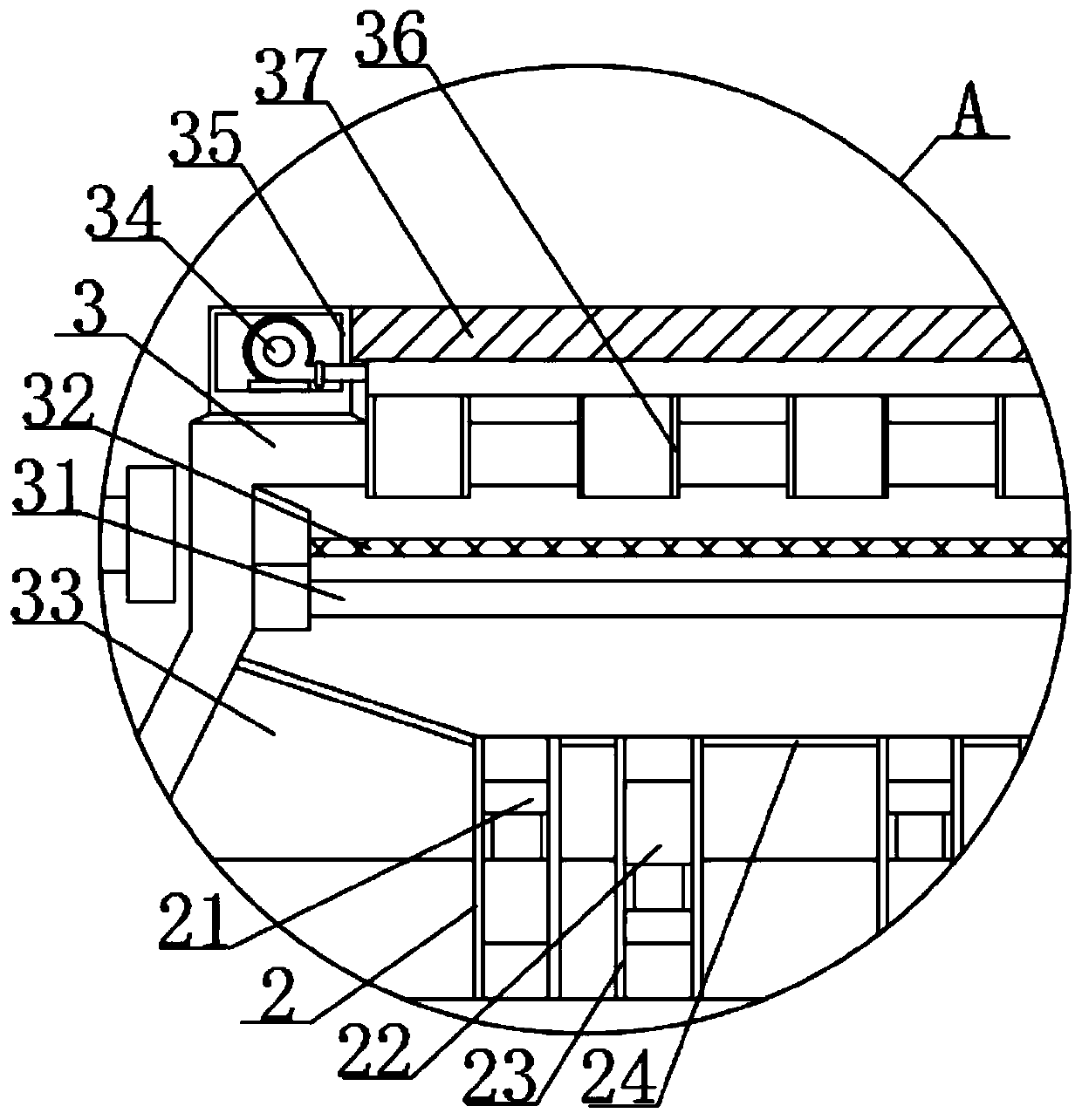

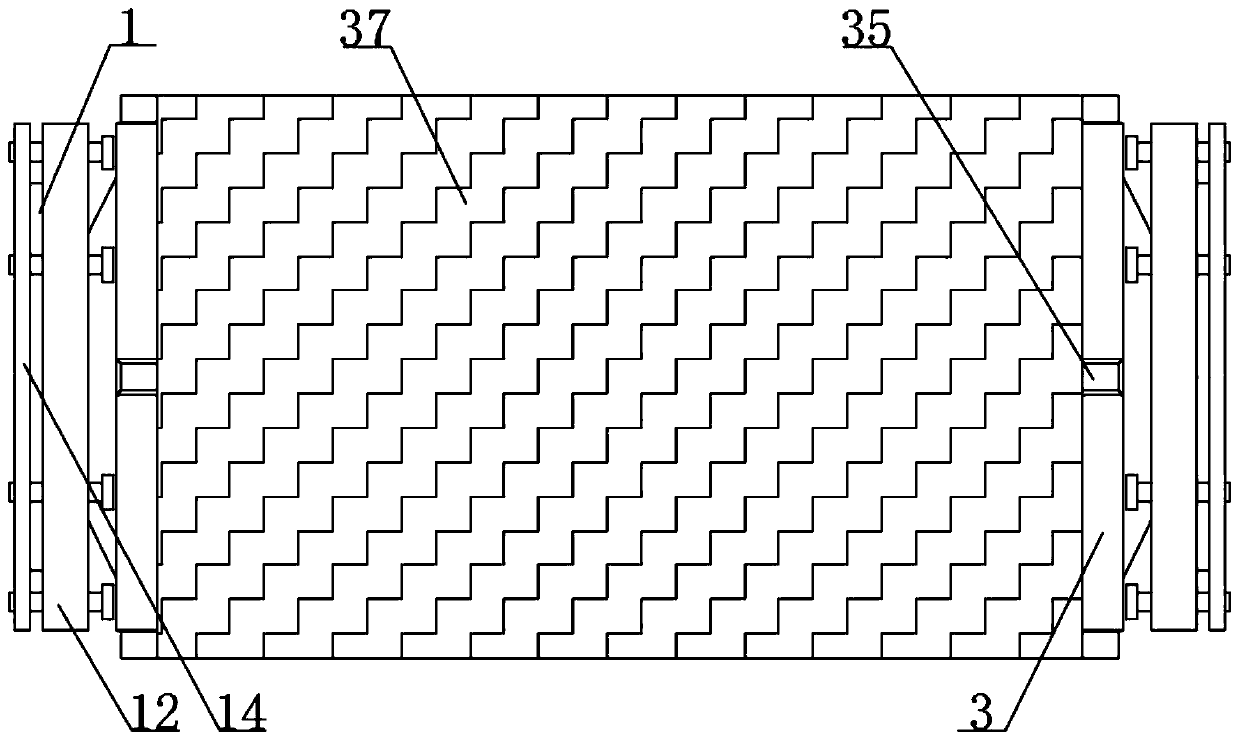

[0026] see Figure 1-5, the present invention provides a technical solution: a structure for preventing temperature overflow of heat conduction pipes for waste heat furnaces in thermal power plants, including a heat conduction pipe body 1; an air intake pipe 2; and a fixed cover 3, and the heat conduction pipe body 1 also includes: a protective net Cover 11, the inner wall of the heat-conducting pipe body 1 is welded with a protective mesh cover 11, and the protective mesh cover 11 is used as a protective device for the heat-conducting pipe body 1, so that the sundries in the gas flowing inside the heat-conducting pipe body 1 are realized Effective blocking, so as to achieve the purpose of placing sundries into the air inlet pipe 2 and the air outlet pipe 23 to cause blockage and reduce the heat conduction effect. There are two fastening frames 12 to facilitate the effective connection of multiple heat-conducting pipe bodies 1 so as to facilitate the heat conduction of waste h...

Embodiment 2

[0028] see figure 1 , figure 2 , image 3 , Figure 4 and Image 6 , the present invention provides a technical solution: a structure for preventing temperature overflow of heat conduction pipes for waste heat furnaces in thermal power plants, including a heat conduction pipe body 1; an air intake pipe 2; and a fixed cover 3, and the heat conduction pipe body 1 also includes: a protective net Cover 11, the inner wall of the heat-conducting pipe body 1 is welded with a protective mesh cover 11, and the protective mesh cover 11 is used as a protective device for the heat-conducting pipe body 1, so that the sundries in the gas flowing inside the heat-conducting pipe body 1 are realized Effective blocking, so as to achieve the purpose of placing sundries into the air inlet pipe 2 and the air outlet pipe 23 to cause blockage and reduce the heat conduction effect. There are two fastening frames 12 to facilitate the effective connection of multiple heat-conducting pipe bodies 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com