A kind of cadmium sulfide/cobalt-phosphate composite photocatalytic material and preparation method thereof

A composite photocatalysis and photocatalysis technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of rare and expensive precious metals, and solve the problems of low sunlight utilization efficiency and cost The effect of low and effective circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

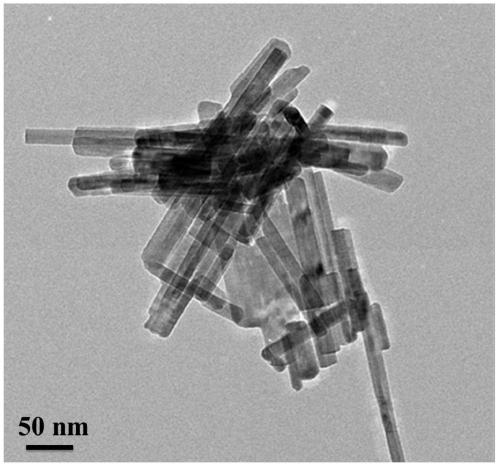

[0029] 1) Prepare 60mL of mixed solution of ethylenediamine and water (volume ratio: 2:1), disperse 12.5mmol of cadmium nitrate tetrahydrate in the above mixed solution under the action of ultrasound, then add 37.5mmol of thiourea, and place it under magnetic force at room temperature Stir vigorously under the action of a stirrer for 6 hours until the solution is uniformly mixed, then transfer the uniformly mixed solution to a 100 mL polytetrafluoroethylene-lined hydrothermal kettle, and then keep it at 160°C for 24 hours. The obtained precipitate was fully centrifuged with water and ethanol, washed, dried in vacuum for 10 hours, and ground into a powdery solid with an agate mortar to obtain cadmium sulfide nanorods.

[0030] 2) Prepare phosphate buffer solution: prepare 0.2 mol / L aqueous solution of disodium hydrogen phosphate dodecahydrate; prepare 0.2 mol / L aqueous solution of sodium dihydrogen phosphate dihydrate; take 61 mL of disodium hydrogen phosphate solution configure...

Embodiment 2

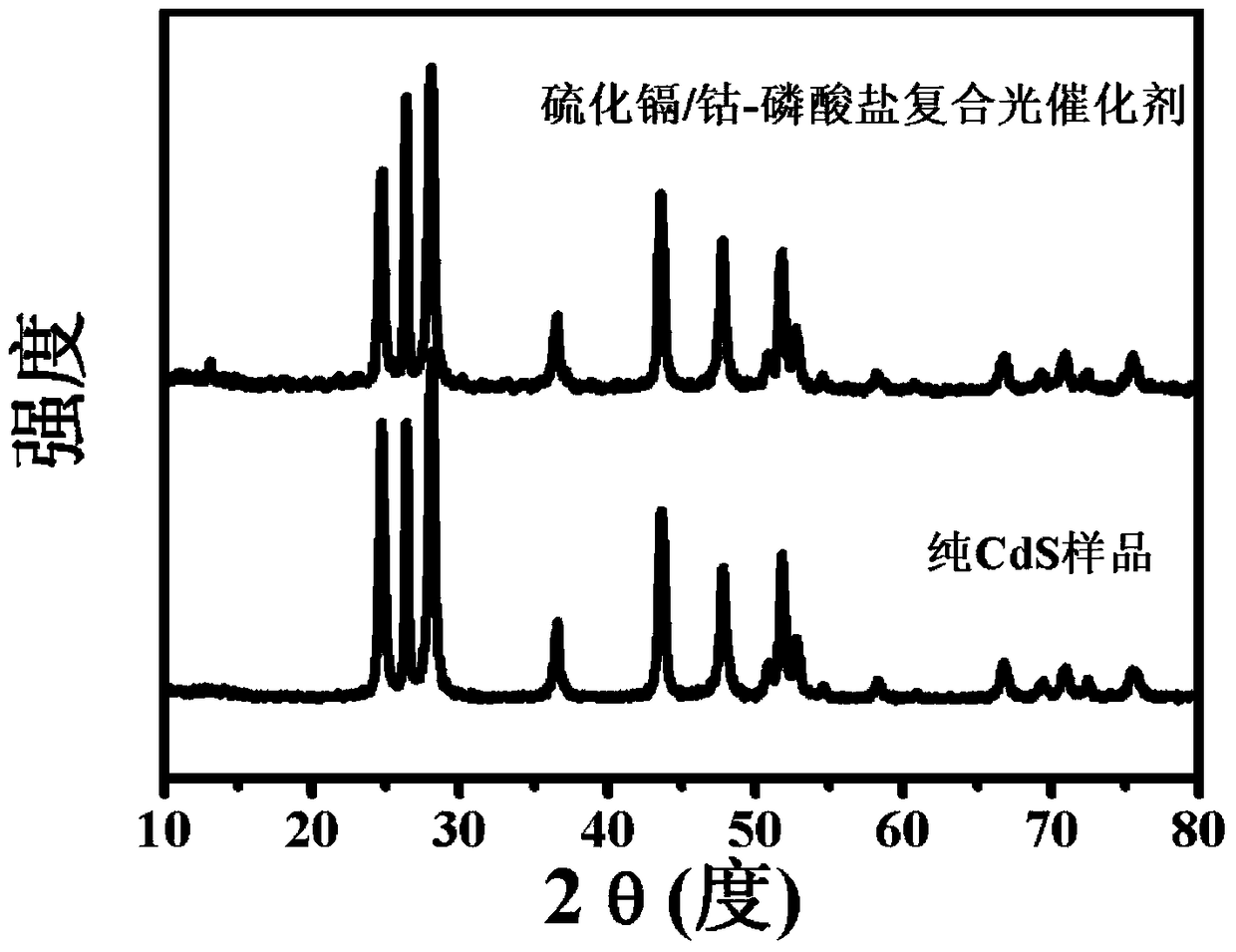

[0036] Pure cadmium sulfide nanorods were prepared by the method in Example 1.

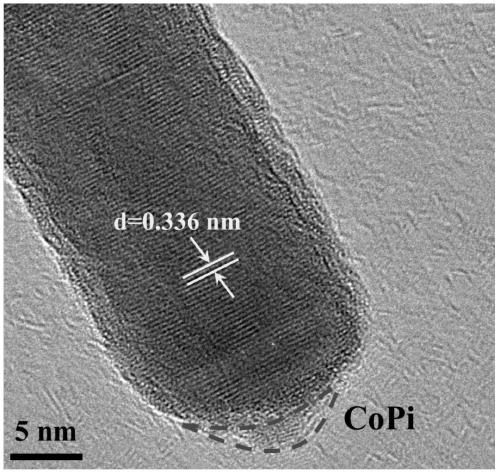

[0037] 2mmol of the cadmium sulfide nanorods prepared above was added to the three-necked flask that was equipped with 50ml of neutral phosphate buffer solution with a concentration of 0.2mol / L prepared by sodium dihydrogen phosphate and disodium hydrogen phosphate, and the three-necked flask was After sealing, ultrasonically disperse for 15 minutes so that the cadmium sulfide nanorods are uniformly dispersed in the above buffer solution. Use a 1mL pipette to take 1mL of cobalt nitrate hexahydrate solution with a concentration of 0.02mol / L, and add it dropwise to the buffer solution in which the cadmium sulfide nanorods are dispersed. 15 minutes to make the cobalt ions evenly dispersed in the solution. The above prepared solution was placed at a distance of 20 cm from a 300W xenon lamp for 3 hours, and then the solution was left to stand until the yellow solid was completely precipitated, and the...

Embodiment 3

[0040] Pure cadmium sulfide nanorods were prepared by the method in Example 1.

[0041] Prepare 60mL of a mixed solution of ethylenediamine and water (volume ratio: 2:1), disperse 12.5mmol of cadmium nitrate tetrahydrate in the above mixed solution under the action of ultrasound, then add 37.5mmol of thiourea, and place in a magnetic stirrer at room temperature Stir vigorously under the action of the solution until the solution is uniformly mixed, then transfer the uniformly mixed solution to a 100mL polytetrafluoroethylene-lined hydrothermal kettle, and then keep it at 180°C for 22 hours. The obtained precipitate is fully centrifuged with water and ethanol, washed, vacuum-dried, and ground into a powdery solid with an agate mortar to obtain cadmium sulfide nanorods.

[0042] 2mmol of the cadmium sulfide nanorods prepared above was added to the three-necked flask that was equipped with 50ml of 0.1mol / L neutral phosphate buffer prepared by sodium dihydrogen phosphate and disodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com