Nitrogen vacancy-doped tungsten nitride modified silver phosphate composite photocatalyst and preparation method thereof

A tungsten nitride modification, nitrogen vacancy technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that catalysts cannot meet the requirements of efficient degradation and removal of organic pollutants, and limit silver phosphate compounding. The promotion and application of photocatalysts, weak photocorrosion resistance, etc., achieve the effects of rich and adjustable electronic structure, reduction of carrier recombination, and promotion of separation and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A nitrogen vacancy doped tungsten nitride modified silver phosphate composite photocatalyst, comprising nitrogen vacancy doped tungsten nitride nanosheets, nitrogen vacancy doped tungsten nitride nanosheets loaded with silver phosphate particles, wherein nitrogen vacancies doped with nitrogen The mass ratio of tungsten oxide nanosheets to silver phosphate particles is 5.97×10 -4 .

[0049] In this embodiment, the atomic percentage of nitrogen vacancies in the nitrogen vacancy-doped tungsten nitride nanosheets is 6%.

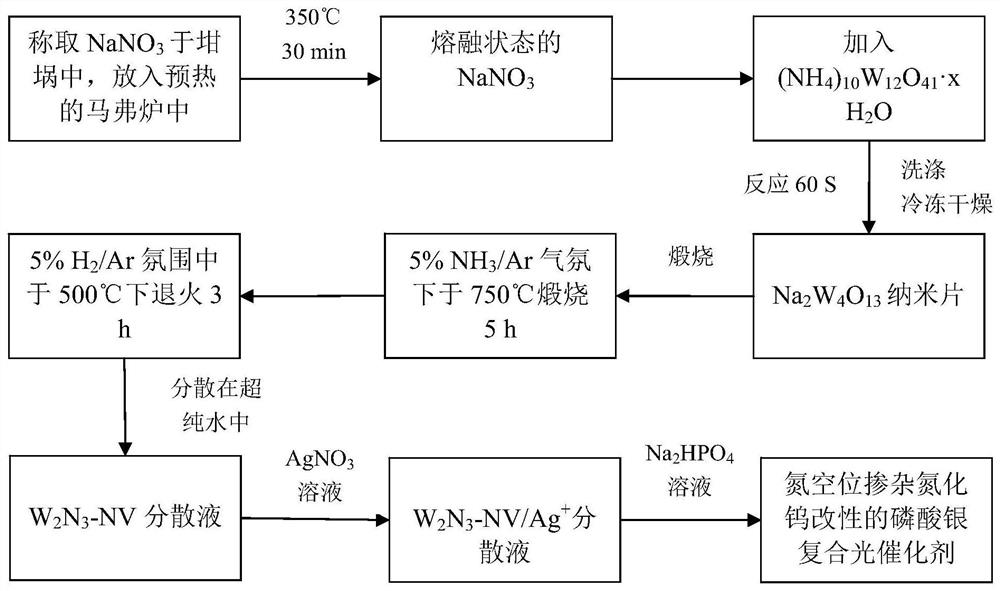

[0050] A preparation method of the nitrogen vacancy doped tungsten nitride modified silver phosphate composite photocatalyst in the above embodiment of the present invention, the preparation process flow chart is as follows figure 1 shown, including the following steps:

[0051] (1) Weigh 8.0g NaNO 3 Put it in a crucible, put it into a preheated muffle furnace, raise the temperature to 350°C and keep it for 30min, so that NaNO 3 Melt to get NaNO in mol...

Embodiment 2

[0059] A nitrogen vacancy-doped tungsten nitride-modified silver phosphate composite photocatalyst, which is basically the same as in Example 1, the only difference being that the mass ratio of nitrogen-vacancy-doped tungsten nitride nanosheets to silver phosphate particles in Example 2 is 1.49×10 -3 .

[0060] A preparation method of a nitrogen vacancy doped tungsten nitride modified silver phosphate composite photocatalyst, which is basically the same as in Example 1, the only difference being that in the step (5) of Example 2, W 2 N 3 - The volume of the NV dispersion is 2.5 mL.

[0061] The silver phosphate composite photocatalyst modified by the nitrogen vacancy doped tungsten nitride prepared in Example 2, denoted as Ag 3 PO 4 @2.5mLW 2 N 3 -NV.

Embodiment 3

[0063] A nitrogen vacancy-doped tungsten nitride-modified silver phosphate composite photocatalyst, which is basically the same as in Example 1, the only difference being that the mass ratio of nitrogen-vacancy-doped tungsten nitride nanosheets to silver phosphate particles in Example 3 is 2.98×10 -3 .

[0064] A preparation method of a nitrogen vacancy-doped tungsten nitride modified silver phosphate composite photocatalyst, which is basically the same as in Example 1, the only difference being that in the step (5) of Example 3, W 2 N 3 - The volume of the NV dispersion is 5.0 mL.

[0065] The silver phosphate composite photocatalyst modified by the nitrogen vacancy doped tungsten nitride prepared in Example 3, denoted as Ag 3 PO 4 @5.0mL W 2 N 3 -NV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com