Outer recirculation canned motor pump

A shielded pump and external circulation technology, applied to pumps, pump components, non-variable pumps, etc., can solve problems such as harsh working environment, heavy ammonia smell, waste of ammonia water, etc., to improve cooling effect, avoid waste, and improve operations environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

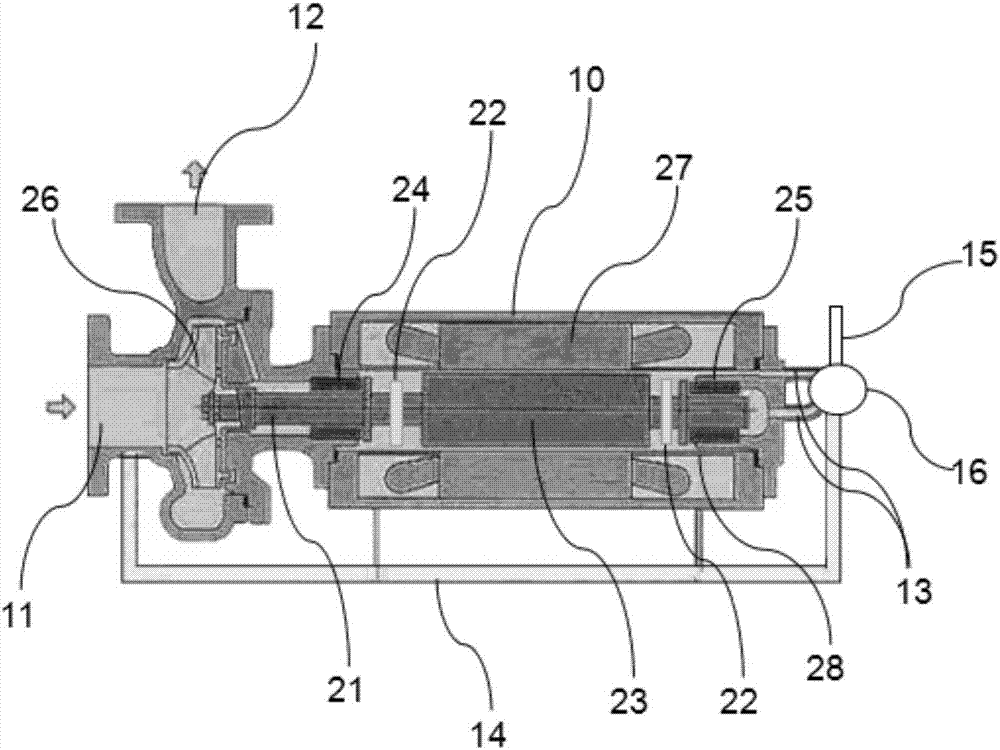

[0020] Now illustrate structural features of the present invention in conjunction with accompanying drawing:

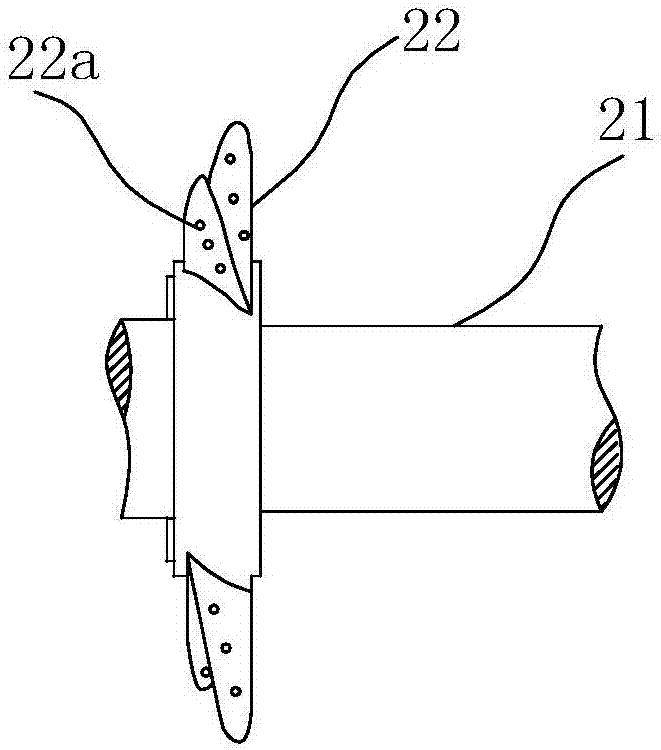

[0021] like figure 1 As shown, the casing 10 of the canned pump is provided with a liquid inlet 11, a liquid outlet 12, and a cooling liquid discharge port 13, and the cooling liquid discharge port 13 is connected to send the motor cooling liquid in the casing 10 back to the The outer circulation pipeline 14 in the pipeline of the liquid inlet 11, the coolant discharge port 13 is also connected to the motor coolant emergency discharge pipeline 15, and the coolant discharge port 15 is equipped with a coolant discharge port 15 The reversing ball valve 16 communicated with the external circulation pipeline 14 or the emergency discharge pipeline 15. The coolant discharge port 13 is located at the position corresponding to the end of the housing 10 and the motor shaft 21, and the motor coolant flows through the front bearing 24, the motor rotor 23, the motor rotor 23, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com