Machining method of T4 aluminum alloy thin-walled disk-shaped part

A processing method and technology for thin-walled discs, which are applied in the field of mechanical processing technology, can solve the problems affecting the processing accuracy and processing quality of parts, the workpiece is easily deformed, and the strength is weak, so as to improve processing quality, improve processing accuracy, and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

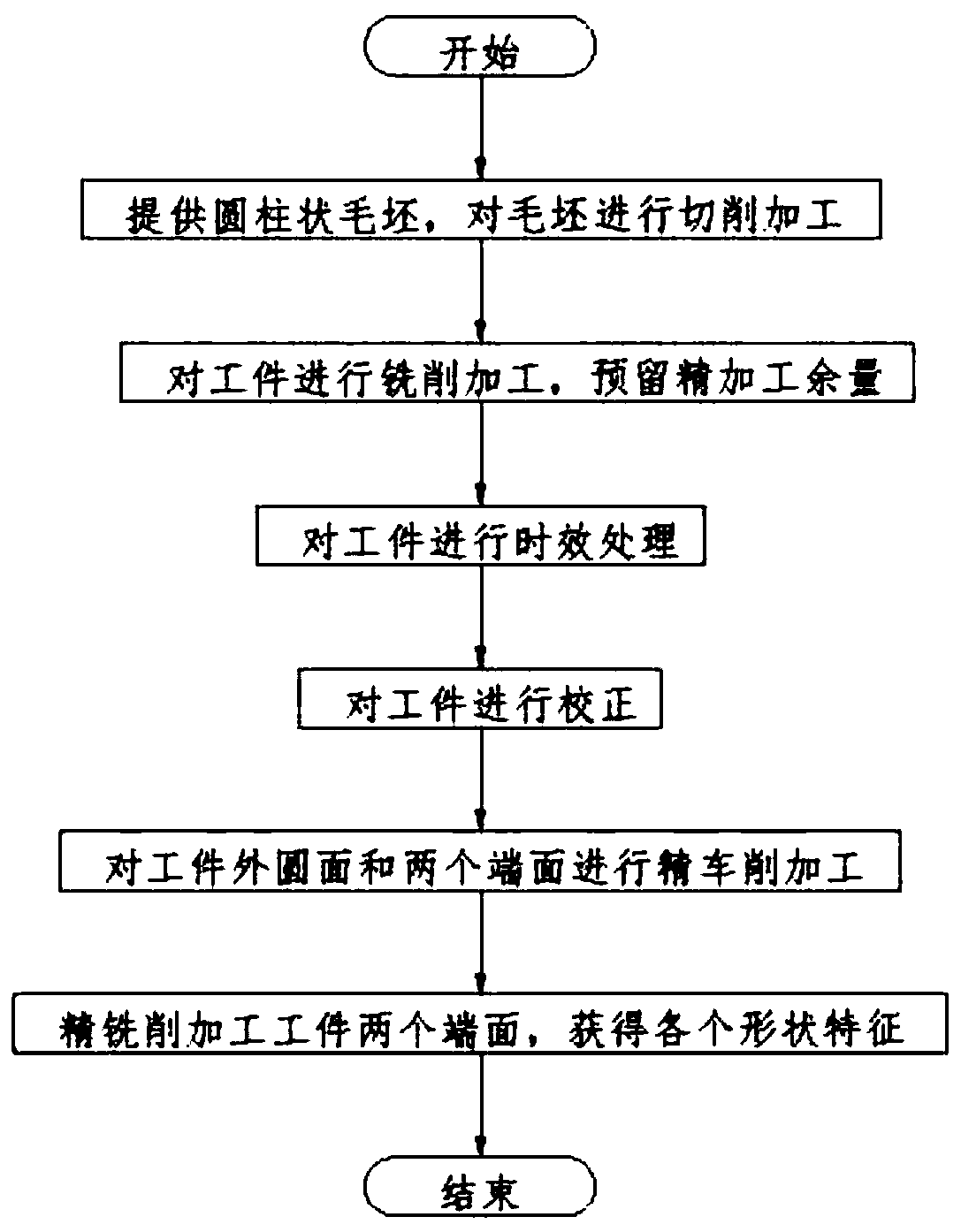

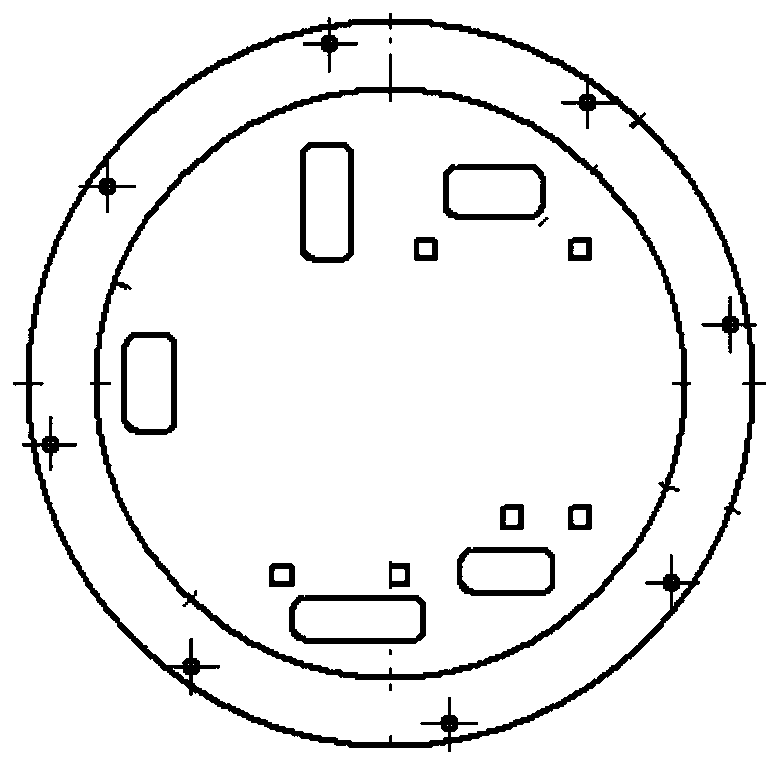

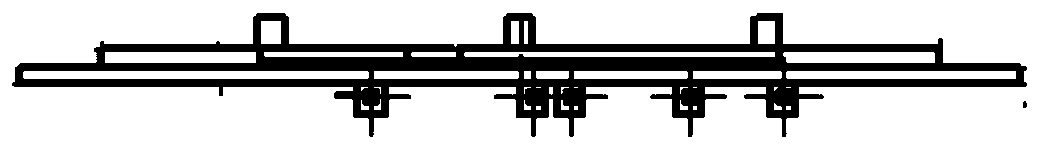

[0024] The invention provides a kind of processing method of T4 aluminum alloy thin-walled disc-shaped parts, such as Figure 1 to Figure 4 shown, including the following steps:

[0025] Step 1: Provide a cylindrical blank, use a lathe to cut the blank, remove most of the material on the surface of the blank, and reserve an appropriate roughing allowance on the outer circular surface and both ends of the blank to obtain the workpiece; the thickness of the roughing allowance is preferably 1mm. The cutting process of the blank by using the lathe is to clamp the blank on the spindle of the lathe through the three-jaw chuck.

[0026] Step 2: Milling the workpiece in step 1 with a milling machine, removing part of the material in the rough machining allowance on the surface of the workpiece, and reserving an appropriate finishing allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com