Continuous track traveling wheel system of tractor and chassis assembly thereof

A technology of walking wheels and tractors, which is applied in the field of tractors, can solve problems such as wheel train structures that cannot achieve vibration reduction effects, and achieve structural mobility and applicability, good stability, safety and comfort in use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

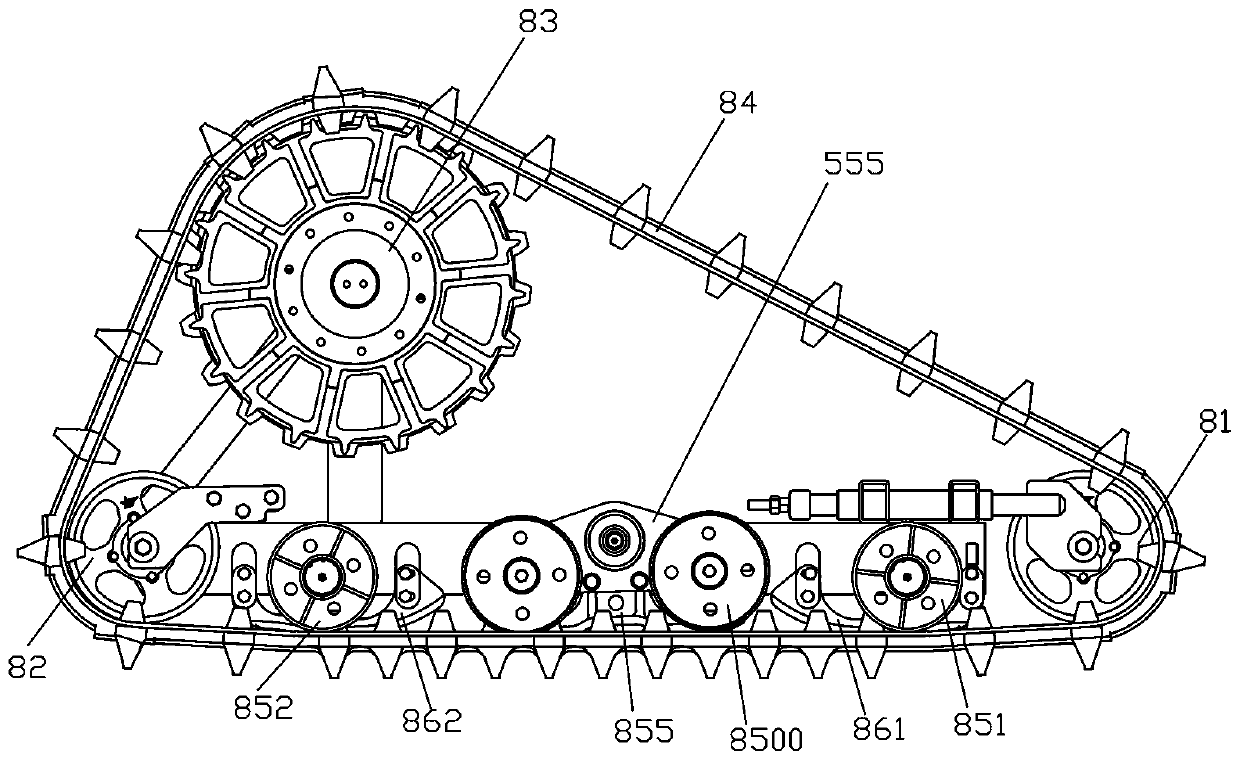

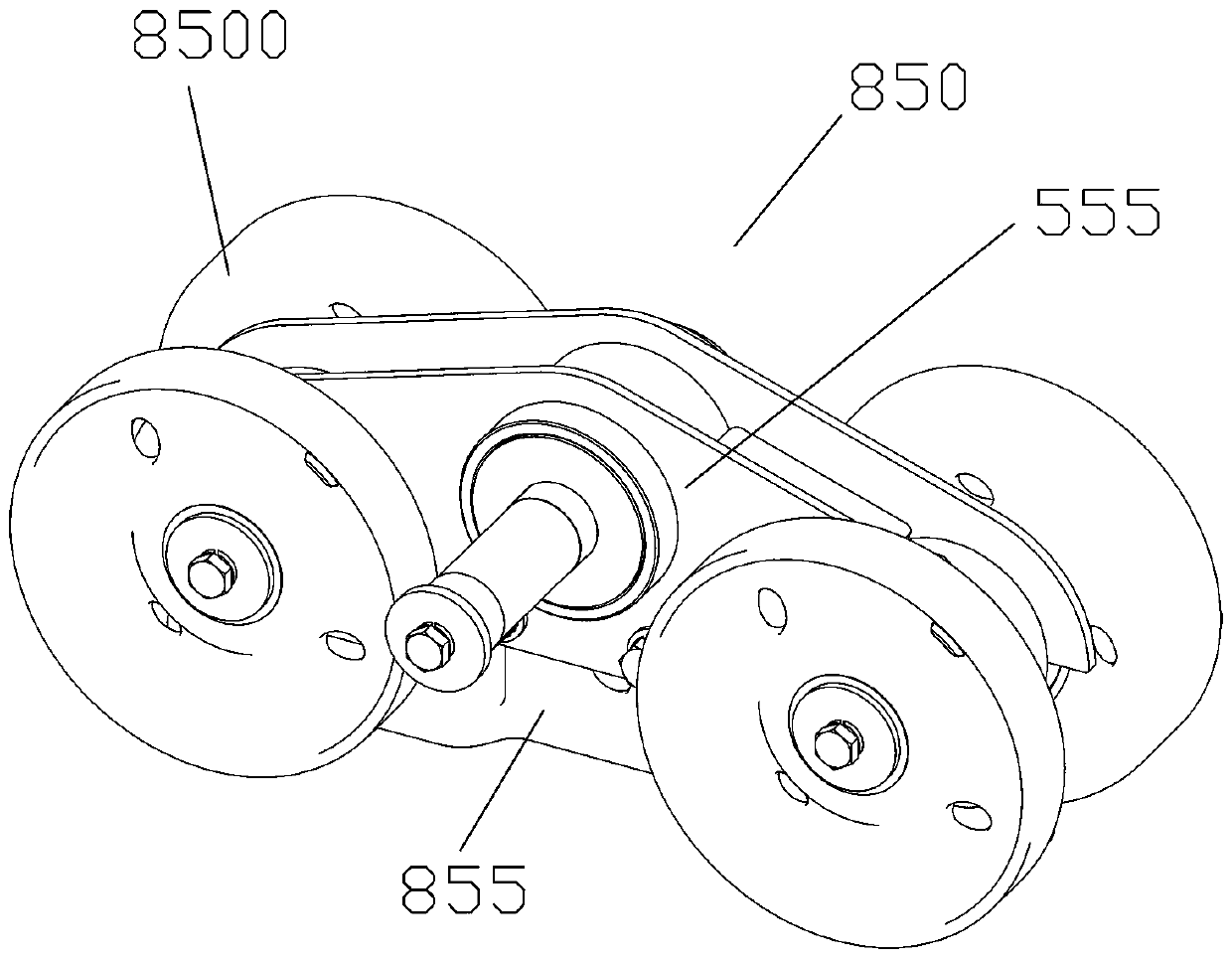

[0055] Example 1, such as figure 1 , 2 , 3, 4, and 5, a crawler wheel train of a tractor includes two wheel train units arranged opposite to each other, and each of the gear train units includes a tension wheel 81, a guide wheel 82, and a tension wheel 81 arranged front and rear. The driving wheel 83 above the guide wheel 82 and the crawler belt 84 wound on the tensioning wheel 81, the guide wheel 82 and the driving wheel 83, the tensioning wheel 81 and the guide wheel 82 are also arranged front and rear in sequence The first weight wheel 851, the balance wheel group 850 and the second support wheel 852, the track 84 is also wound around the first support wheel 851, the balance wheel group 850 and the second support wheel 852 On the lower side, the balance wheel set 850 has two pairs of front and rear balance wheels 8500 that can float up and down, and the height of the tension wheel 81 and the guide wheel 82 are higher than the height of the first support wheel 851 and Both ar...

Embodiment 2

[0065] Example 2, such as Image 6 As shown, a tractor chassis assembly, the chassis frame, the crawler train of the tractor described in embodiment 1 is installed on the chassis frame, and a gearbox is also installed on the chassis frame 400, engine 401, shock absorber 402, the shock absorber 402 has two and are respectively installed between the lower left side of the engine 401 and the upper left long beam 701 of the chassis frame and the lower left side of the engine 401 and the upper left side of the chassis frame Between the right long beam 702.

Embodiment 3

[0066] Example 3, such as Figure 7 , 8 9. As shown in 9, a crawler tractor chassis frame includes a lower frame 71 and an upper frame 72 fixed above the lower frame 71. The lower frame 71 is provided with two left and right sides above the rear side. There are two surrounding jackets 73 for the left and right side drive wheel shells of the gearbox to be sleeved respectively. The surrounding jacket 73 has a rotation space 730 for the drive wheel shells of the gearbox to rotate. The drive wheel housing is a circular protective housing outside the drive shaft of the gearbox for driving the tractor drive wheels. The sleeve connection between the surrounding jacket 73 and the drive wheel shells on the left and right sides of the gearbox should not be locked, and the drive wheel shells of the gearbox should be installed in the surrounding jacket 73 to rotate in the rotating space 730 In this way, when the tractor is vibrating, especially when the engine is vibrating, or when the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com