ECP wallboard supporting grouting material and preparation method thereof

A technology of grouting material and wallboard, applied in the field of ECP wallboard matching grouting material and its preparation, to achieve low cost, solve drying shrinkage, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

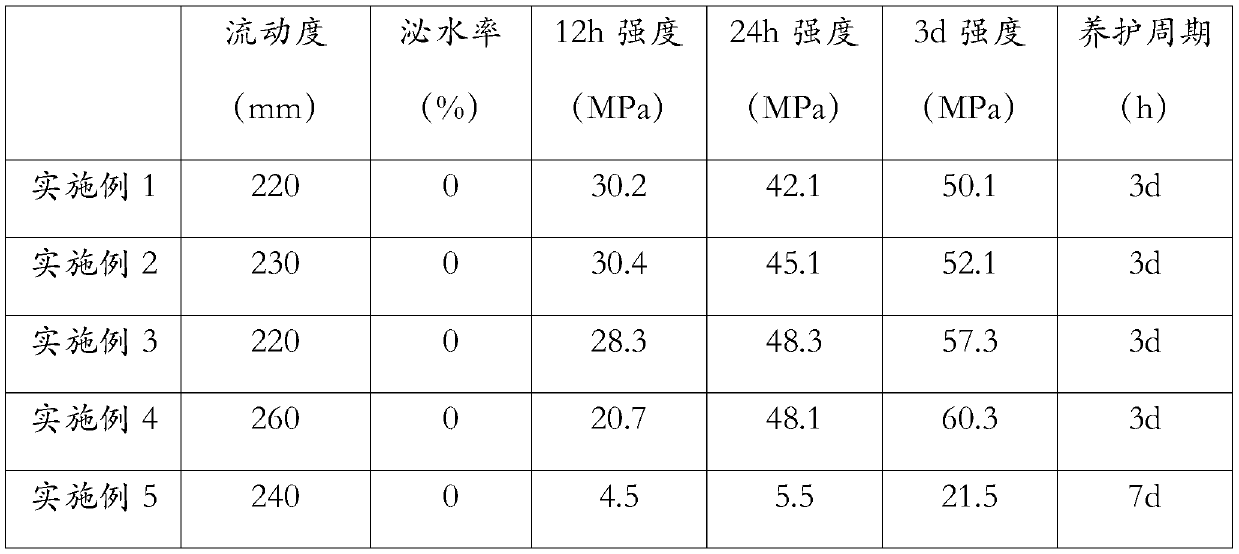

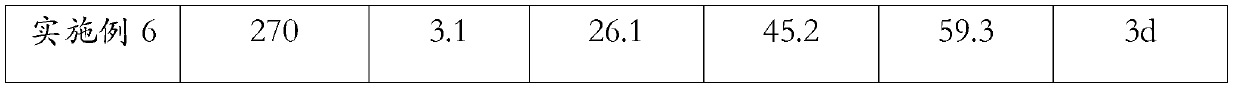

Examples

Embodiment 1

[0027] A grouting material for ECP wallboards, comprising the following components in weight percent: 35% of ordinary Portland cement with a strength label of 42.5R, 17.48% of sulphoaluminate cement, and 40% of medium-fine sand with a fineness modulus of 0.9 %, 1% of methyl cellulose ether, 0.02% of polypropylene fiber, 4.5% of calcium oxide expansion agent, 1% of early strength agent, 1% of naphthalene powder water reducer, and the sum of the total mass percentage is 100%.

[0028] The preparation method of the above-mentioned ECP wallboard matching grouting material is as follows:

[0029] 1) Weigh each raw material in proportion, then dry the medium-fine sand until the water content is below 0.5%, screen out particles larger than 4.75mm, and obtain medium-fine sand with a fineness modulus of 1.6-2.3 for use;

[0030] 2) Mix ordinary Portland cement with a strength label of 42.5R and sulphoaluminate cement to obtain a cement mixture; then add methyl cellulose ether, polyprop...

Embodiment 2

[0033] A grouting material for ECP wallboards, comprising the following components in weight percent: 18.58% of ordinary Portland cement with a strength label of 52.5, 20% of sulphoaluminate cement, and 55% of medium-fine sand with a fineness modulus of 1.8 , 0.02% of hydroxypropyl methylcellulose ether, 0.1% of polypropylene fiber, 4% of calcium sulfoaluminate expansion agent, 0.3% of early strength agent, and 2% of polycarboxylic acid powder superplasticizer.

[0034] The preparation method of the above-mentioned ECP wallboard matching grouting material is as follows:

[0035] 1) Weigh each raw material in proportion, dry the medium-fine sand until the moisture content is below 0.5%, screen out particles larger than 4.75mm, and obtain medium-fine sand with a fineness modulus of 1.8 for subsequent use;

[0036] 2) Mix ordinary Portland cement with a strength of 52.5 and sulphoaluminate cement to obtain a cement mixture; then mix hydroxypropyl methylcellulose ether, polypropyl...

Embodiment 3

[0039] A grouting material for ECP wallboards, comprising the following components in weight percent: 19.79% of slag Portland cement with a strength label of 52.5, 25% of sulphoaluminate cement, and medium-fine sand with a fineness modulus of 1.0-1.5 50%, methyl cellulose ether 0.01%, glass fiber 0.8%, iron filings expansion agent 3.1%, early strength agent 0.3%, naphthalene powder superplasticizer 1%, the sum of the total mass percentage is 100%.

[0040] The preparation method of the above-mentioned ECP wallboard matching grouting material is as follows:

[0041] 1) Weigh each raw material in proportion, dry the medium-fine sand until the moisture content is below 0.5%, screen out particles larger than 4.75mm, and obtain medium-fine sand with a fineness modulus of 1.6-2.3 for use;

[0042] 2) Mix slag Portland cement with a strength of 52.5 and sulphoaluminate cement to obtain a cement mixture, and then add methyl cellulose ether, glass fiber, iron filings expansion agent, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com