Antifreeze ready mixed mortar and preparation method thereof

A technology for ready-mixed mortar and anti-freezing agent, which is applied in the field of anti-freezing ready-mixed mortar and its preparation, can solve the problems of long setting time and poor anti-freezing performance of ready-mixed mortar, and achieves improved waterproof and impermeability performance, low cost and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

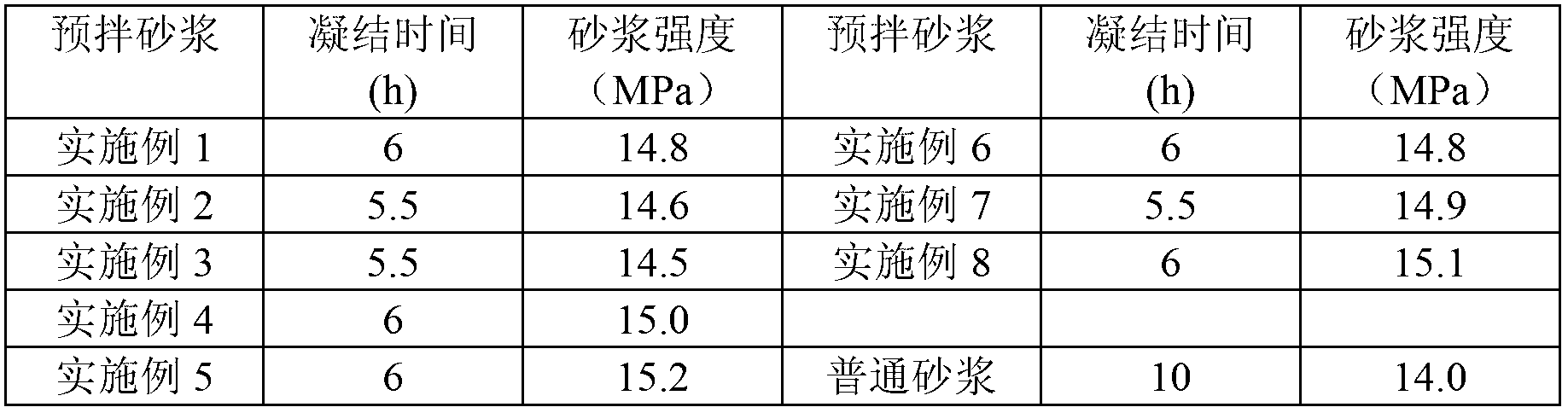

Examples

Embodiment 1

[0024] Ready-mixed mortar includes the following components by weight percentage: Portland cement 35%, medium-fine sand with a fineness modulus of 1.6-2.3 60%, cellulose ether polymer 0.3%, engineering fiber 2.0%, Expansion agent 1.2%, water reducing agent 1.0%, antifreeze 0.5%.

[0025] among them,

[0026] The cellulose ether polymer is methyl cellulose ether;

[0027] Engineering fiber is polypropylene fiber;

[0028] The expansion agent is UEA-IV expansion agent;

[0029] The water reducing agent is a naphthalene-based powder water reducing agent;

[0030] The antifreeze is sodium nitrite.

[0031] The preparation method is as follows:

[0032] 1) Dry the medium-fine sand to a moisture content below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0033] 2) Add cellulose ether polymer, engineering fiber, expansion agent, water reducing agent and antifreeze to cement, and stir it evenly to obtain additive cement mixture; ...

Embodiment 2

[0036] Ready-mixed mortar includes the following components by weight percentage: ordinary Portland cement 30%, medium-fine sand with a fineness modulus of 1.6-2.3 64.7%, cellulose ether polymer 0.1%, engineering fiber 0.1% , Expanding agent 4.0%, water reducing agent 0.1%, antifreeze 1.0%.

[0037] among them,

[0038] The cellulose ether polymer is hydroxypropyl methyl cellulose ether;

[0039] Engineering fiber is glass fiber;

[0040] The expansion agent is a mixture of UEA expansion agent, calcium oxide expansion agent, iron filings expansion agent and alum expansion agent;

[0041] The water reducing agent is a polycarboxylic acid powder water reducing agent;

[0042] The antifreeze is sodium chloride.

[0043] The preparation method is as follows:

[0044] 1) Dry the medium-fine sand to a moisture content below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0045] 2) Add cellulose ether polymer, engineering fiber, e...

Embodiment 3

[0048] Ready-mixed mortar, including the following components by weight percentage: 27.6% slag portland cement, 70% medium-fine sand with a fineness modulus of 1.6-2.3, 0.2% cellulose ether polymer, and 1.0% engineering fiber , Expanding agent 0.1%, water reducing agent 1.0%, antifreeze 0.1%.

[0049] among them,

[0050] The cellulose ether polymer is a mixture of methyl cellulose ether and hydroxypropyl methyl cellulose ether;

[0051] Engineering fiber is a mixture of polypropylene fiber and glass fiber;

[0052] The expansion agent is an iron filings expansion agent;

[0053] The water reducing agent is an aliphatic powder water reducing agent;

[0054] The antifreeze is calcium chloride.

[0055] The preparation method is as follows:

[0056] 1) Dry the medium-fine sand to a moisture content below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0057] 2) Add cellulose ether polymer, engineering fiber, expansion agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com