Antifreeze ready mixed mortar and preparation method thereof

A technology of ready-mixed mortar and antifreeze, which is applied in the field of antifreeze ready-mixed mortar and its preparation, which can solve the problems of long setting time and poor antifreeze performance of ready-mixed mortar, achieve improved waterproof and impervious performance, low cost, and solve the problem of dryness shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

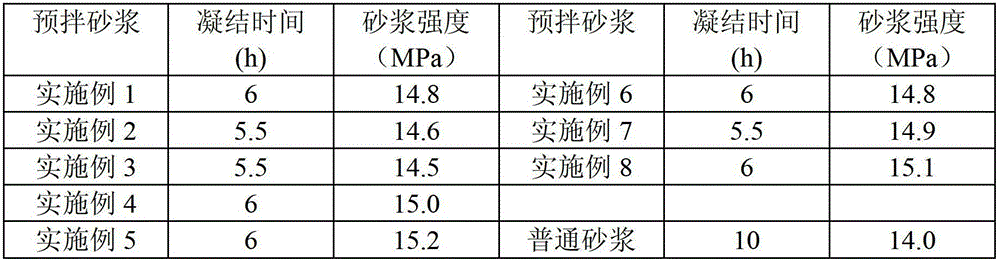

Examples

Embodiment 1

[0024] Ready-mixed mortar, including the following components in weight percentage: Portland cement 35%, medium-fine sand with a fineness modulus of 1.6-2.3 60%, cellulose ether polymer 0.3%, engineering fiber 2.0%, 1.2% expansion agent, 1.0% water reducer, 0.5% antifreeze.

[0025] in,

[0026] The cellulose ether polymer is methyl cellulose ether;

[0027] The engineering fiber is polypropylene fiber;

[0028] The expansion agent is UEA-IV expansion agent;

[0029] The water reducer is a naphthalene powder water reducer;

[0030] Antifreeze is sodium nitrite.

[0031] The preparation method is as follows:

[0032] 1) Dry the medium-fine sand until the moisture content is below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0033] 2) adding cellulose ether polymer, engineering fiber, expansion agent, water reducer and antifreeze to cement, and stirring evenly to obtain additive cement mixture;

[0034]...

Embodiment 2

[0036] Ready-mixed mortar, including the following components in weight percentage: 30% of ordinary Portland cement, 64.7% of medium-fine sand with a fineness modulus of 1.6-2.3, 0.1% of cellulose ether polymer, and 0.1% of engineering fiber , expansion agent 4.0%, water reducer 0.1%, antifreeze 1.0%.

[0037] in,

[0038] The cellulose ether polymer is hydroxypropyl methylcellulose ether;

[0039] The engineering fiber is glass fiber;

[0040] The expansion agent is a mixture of UEA expansion agent, calcium oxide expansion agent, iron filings expansion agent and alum expansion agent;

[0041] The water reducer is polycarboxylate powder water reducer;

[0042] Antifreeze is sodium chloride.

[0043] The preparation method is as follows:

[0044] 1) Dry the medium-fine sand until the moisture content is below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0045] 2) adding cellulose ether polymer, engineer...

Embodiment 3

[0048] Ready-mixed mortar, including the following components in weight percentage: 27.6% of slag Portland cement, 70% of medium-fine sand with a fineness modulus of 1.6-2.3, 0.2% of cellulose ether polymer, and 1.0% of engineering fiber , 0.1% expansion agent, 1.0% water reducer, 0.1% antifreeze.

[0049] in,

[0050] The cellulose ether polymer is a mixture of methyl cellulose ether and hydroxypropyl methyl cellulose ether;

[0051] Engineering fiber is a mixture of polypropylene fiber and glass fiber;

[0052] The expansion agent is an iron filings expansion agent;

[0053] The water reducer is an aliphatic powder water reducer;

[0054] Antifreeze is calcium chloride.

[0055] The preparation method is as follows:

[0056] 1) Dry the medium-fine sand until the moisture content is below 0.5%, and screen out particles larger than 4.75mm to obtain medium-fine sand with a fineness modulus of 1.6-2.3;

[0057] 2) adding cellulose ether polymer, engineering fiber, expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com