A method for manufacturing an ultra-low temperature high-strength non-magnetic stainless steel impeller shaft

A non-magnetic stainless steel and manufacturing method technology, applied in the field of impeller shaft manufacturing, can solve problems such as inability to meet multiple performance index requirements at the same time, achieve low magnetic permeability, scientific and reasonable design, and stable austenite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

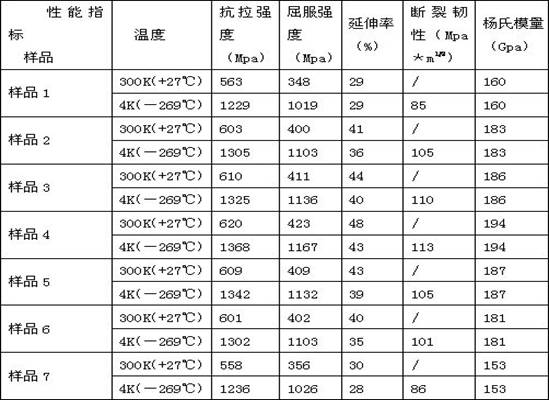

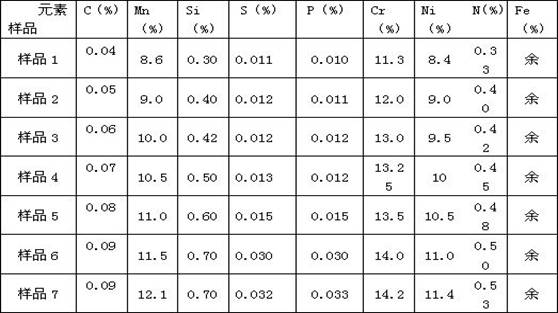

[0023] Embodiment: This embodiment specifically relates to a manufacturing method of an ultra-low temperature, high-strength, non-magnetic stainless steel impeller shaft. The manufacturing method rationally designs the content of each component of the steel type and strictly controls the content of harmful elements during smelting to increase the strength of molten steel. Purity, and the step heating method is used to heat the steel ingot, so that it has high strength, low magnetic permeability and stable austenite structure at ultra-low temperature.

[0024] A method for manufacturing an ultra-low temperature, high-strength, non-magnetic stainless steel impeller shaft provided in this embodiment includes the following steps:

[0025] (1) Select high-quality raw materials: micro-carbon ferrochrome, nickel plate and metal manganese, among which the nickel plate is 0# nickel plate; then use 5%-7% dilute sulfuric acid to clean the above raw materials to remove the rust that may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com