An experimental verification device for crack growth life of a wheel disc

A technology for crack extension life and verification device, which is applied in the field of wheel disk crack extension experiment verification, can solve the problem that the force of the two tie rods cannot be guaranteed to be the same, and achieve the effects of avoiding errors, compact device structure, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

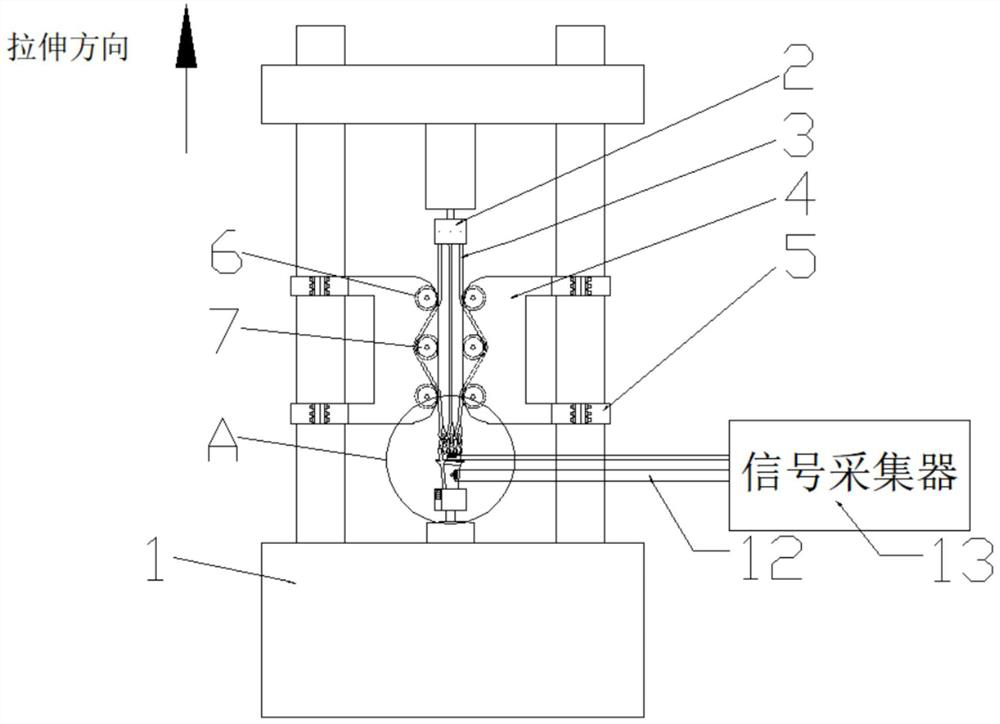

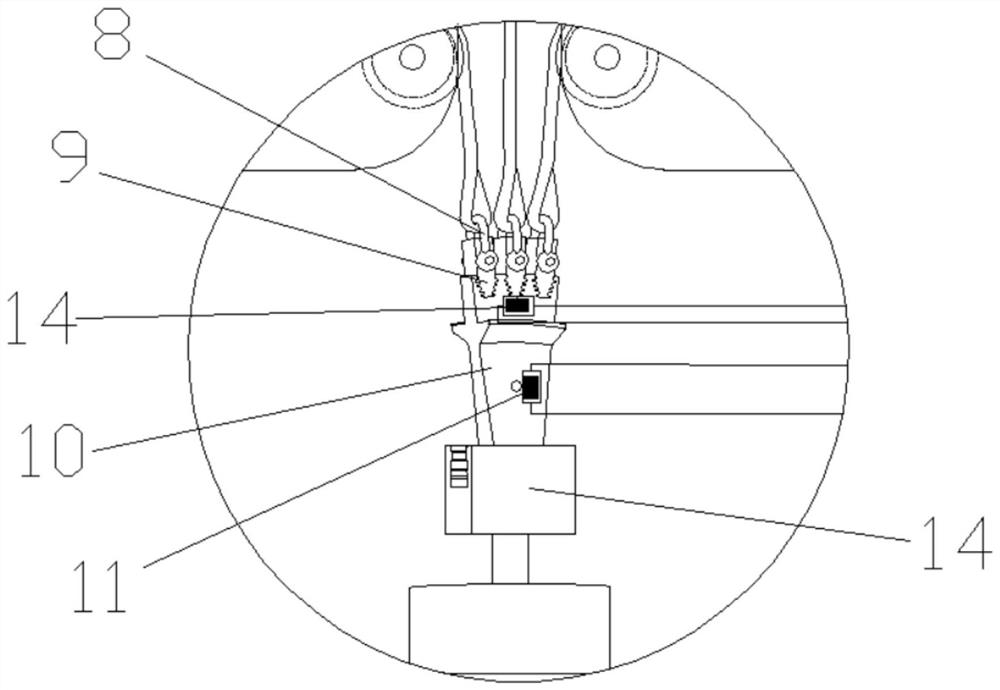

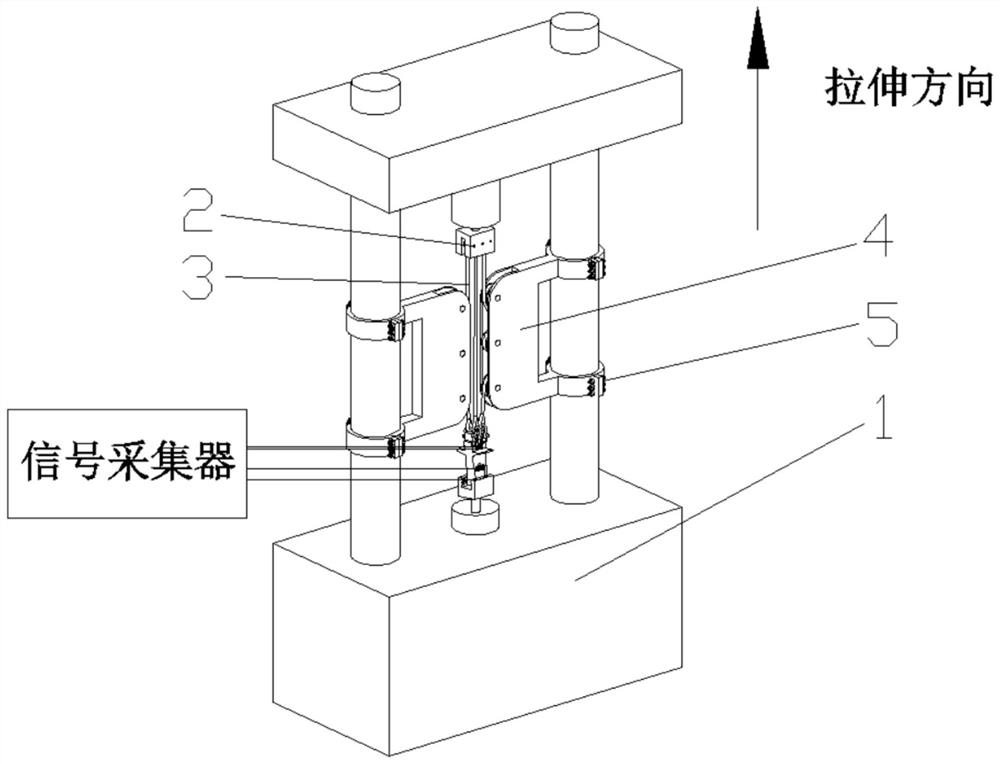

[0017] like Figure 1 to Figure 5 As shown, the experimental verification device for a crack extension life of a wheel disk according to the present invention includes an MTS testing machine 1, a steel wire rope fixing seat 2, a steel wire rope 3, a fixing frame 4, a flange 5, a first fixed pulley 6, a second Fixed pulley 7, U-shaped shackle 8, toothed loading block 9, wheel disc model 10, wheel disc fixture 14, wire 12, signal collector 13 and broken wire piece 11;

[0018] The wheel plate sub-model 10 is fixedly installed on the workbench of the MTS testing machine 1 through the wheel disc clamp 14, and the tooth-shaped loading blocks 9 are installed in the three tongues and grooves on the upper end of the wheel plate sub-model 10, and the upper ends of the tooth-shaped loading blocks 9 are hinged. There is a U-shaped shackle 8, and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com