Punching abrasion testing device based on control energy

A wear test and energy technology, which is used in measuring devices, testing wear resistance, and testing material strength by applying repetitive force/pulse force. , to achieve the effect of enhancing practicability and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

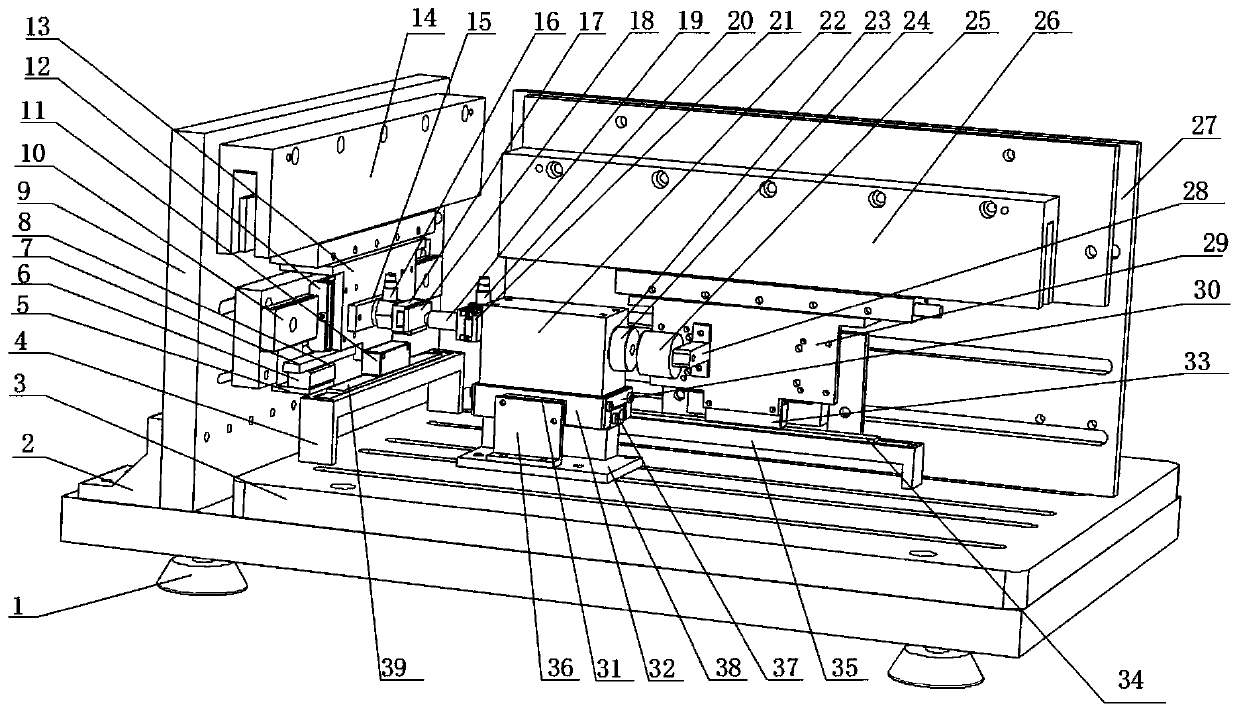

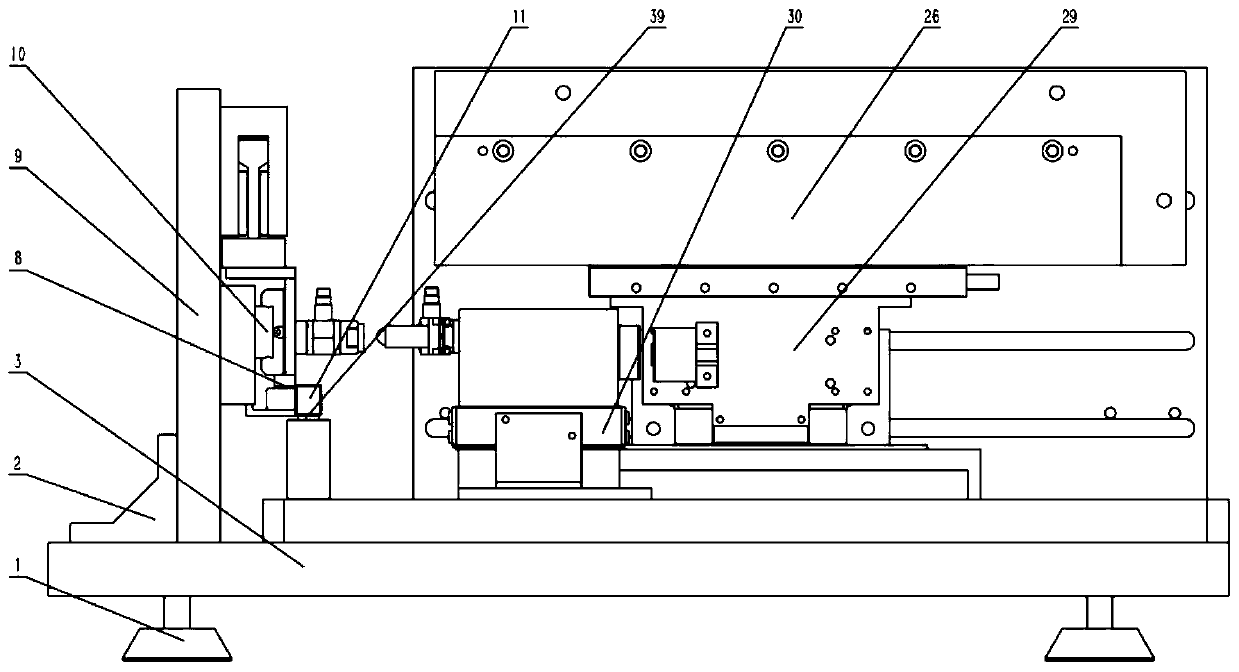

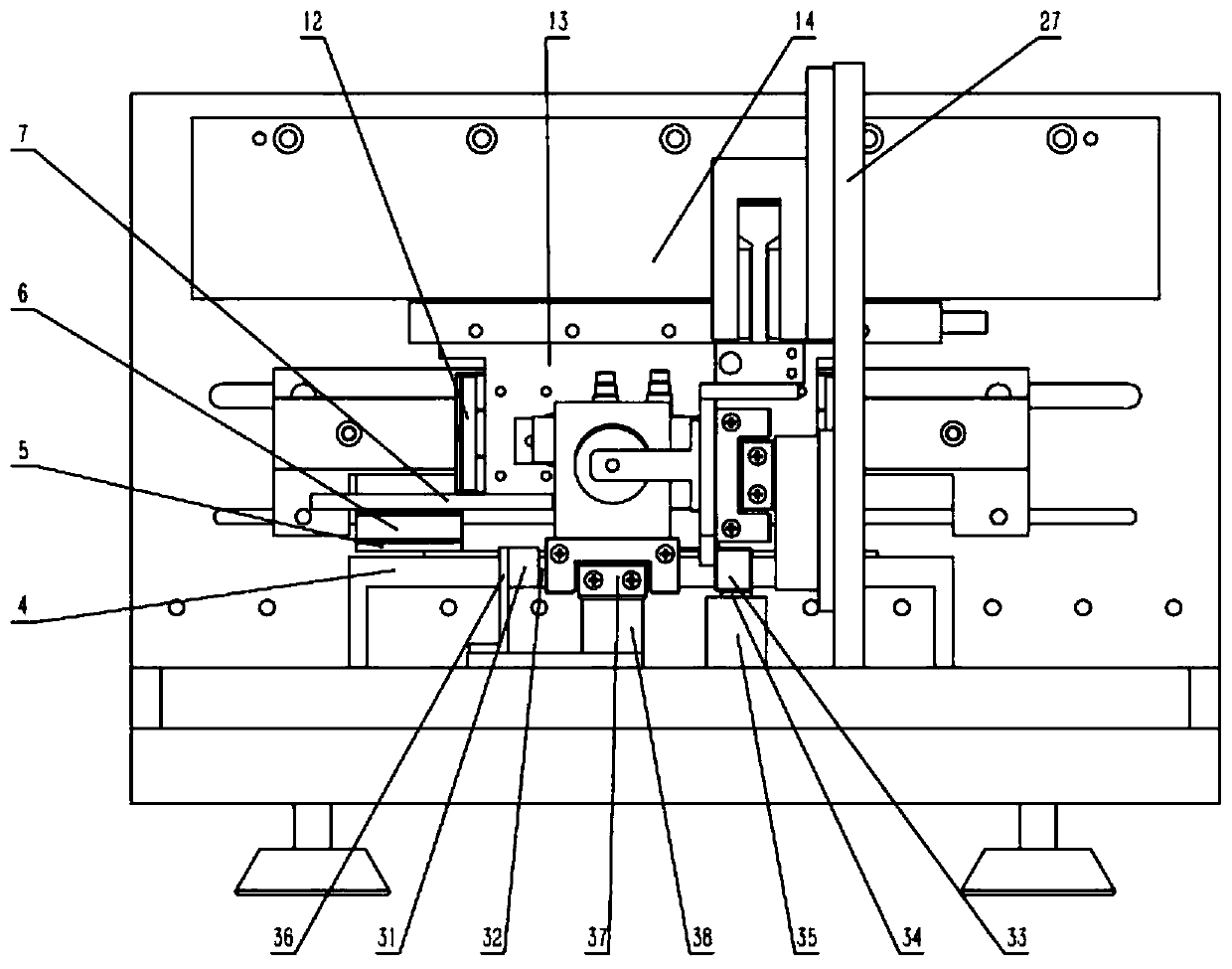

[0035] Such as Figure 1-5 As shown, this embodiment provides a punching wear test device based on control energy, which is divided into mechanical components, control system and data acquisition system, mainly including tangential drive unit, impact unit, and impact drive unit. The tangential drive unit, the impact unit, and the impact drive unit are all provided with a position detection mechanism; the tangential drive unit is used to drive the sample 18 to perform tangential movement; the impact unit is driven by the impact drive unit to perform reciprocating motion, The moving direction of the sample 18 is perpendicular to the moving direction of the impact unit, and the farthest end of the impact head 19 of the impact unit collides with the sample 18 to wear.

[0036] During implementation, also comprise frame, frame comprises base 1, base plate 3, side plate 9 and front plate 27; Described base plate 3 is positioned at base 1 top, and mutually perpendicular between descr...

Embodiment 2

[0050]The difference between this embodiment and Embodiment 1 is that the sample 18 is a tubular sample, and the tubular sample is installed on the pipe clamp 1708 through a splint 1710 and two symmetrical hexagonal bolts 1709; 1708 is fixed on the single-head heating tube fixing plate 1702 by bolts; the single-head heating tube fixing plate 1702 is installed on the impact force sensor through the heat-insulating ceramic plate 1703; the single-head heating tube fixing plate 1702 is installed through clearance fit There are two single-head heating tubes 1704 , and a thermocouple thermometer 1705 is set in the middle of the single-head heating tube fixing plate 1702 ; a heat-insulating ceramic column 1712 is set between the impact unit and the impact head 19 . During implementation, the heat insulating ceramic column 1712 is located between the impact head 19 and the tangential force sensor mounting frame 21; the heat insulating ceramic column / plate is used for heat insulation fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com