Multi-signal synchronous feedback device for oil detection

A technology of feedback device and detection device, which is applied in the direction of measuring device, suspension and porous material analysis, instrument, etc., can solve the problems of limited detection ability and single measurement parameter, and achieve the effect of synchronous detection of multiple signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

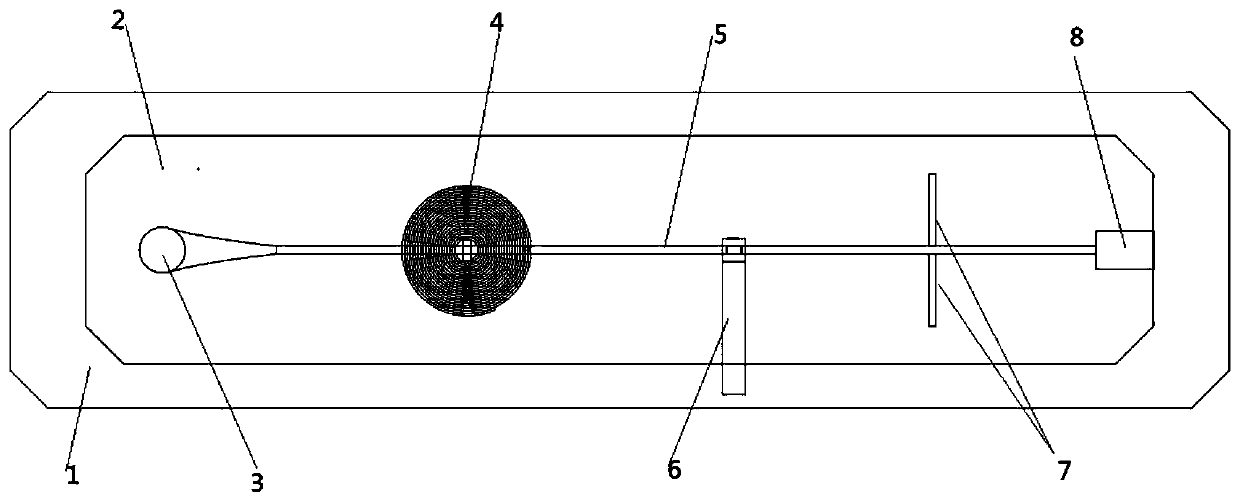

[0041] like figure 1 As shown, the present invention provides a multi-signal synchronous feedback device for oil detection, including a detection device and an excitation-detection unit.

[0042]The detection device includes a microfluidic chip. The microfluidic chip includes a substrate 1 and a chip body arranged on the substrate 1. One end of the chip body is provided with a microchannel inlet 3, and the other end is provided with a microchannel 5 with a microchannel outlet 8. The microchannel 5 is also provided with a sensing unit I4, a deposition tank 6, and a sensing unit II7 in sequence; the microfluidic chip also includes a model material 2, and the substrate 1 is placed at the bottom of the microchannel 5 for fixing the microfluidic chip, the sensor unit The sensing unit I4 and the sensing unit II7, the model material 2 is poured on the outside of the microfluidic chip, the sensing unit I4 and the sensing unit II7.

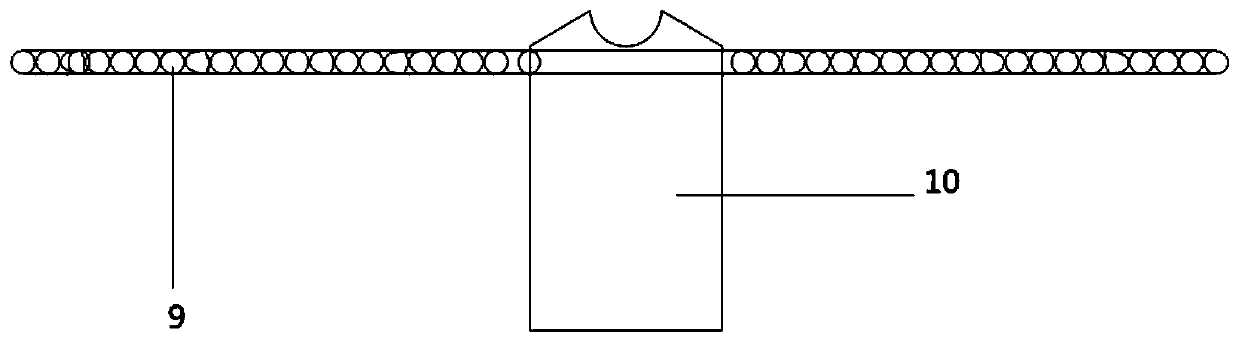

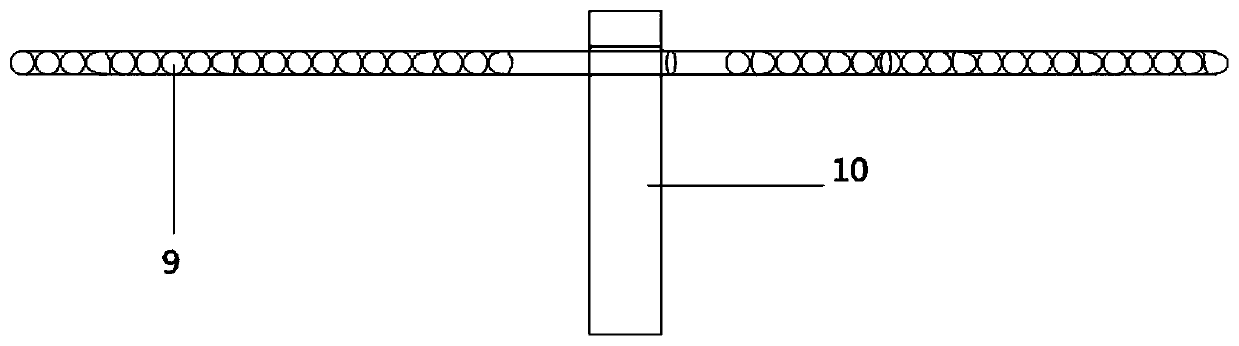

[0043] like figure 2 , 3 As shown, the sensing u...

Embodiment 2

[0049] like figure 1 As shown, (on the basis of Embodiment 1), the present invention also provides a method for making a multi-signal synchronous feedback device for oil detection, comprising the following steps:

[0050] S1: Fix the microchannel inlet mold, the microchannel mold, the silicon steel sheet 10 wound with the single-layer coil 9, and two copper rods on the substrate 1 according to a predetermined position;

[0051] S2: pouring the molding material 2 into the substrate 1, wherein the two lead wires connecting the single-layer coil 9 and the two lead wires connecting the copper rods are arranged outside the modeling material 2 so that they are not poured by the modeling material;

[0052] S3: Place the chip poured with the model material 2 in an oven and bake at a temperature of 80° C. for 1 hour, so that the model material 2 is cured;

[0053] S4: Extract the micro-channel mold from the heated and cured model material 2, extract the micro-channel inlet mold to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com