Multi-view stereoscopic vision detection device and method for bridge base nut-screw looseness or fracture

A multi-eye stereo vision and detection method technology, applied in the detection field, can solve problems such as high labor costs, blurred images, unsafe heights, etc., and achieve the effect of compact shell structure, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

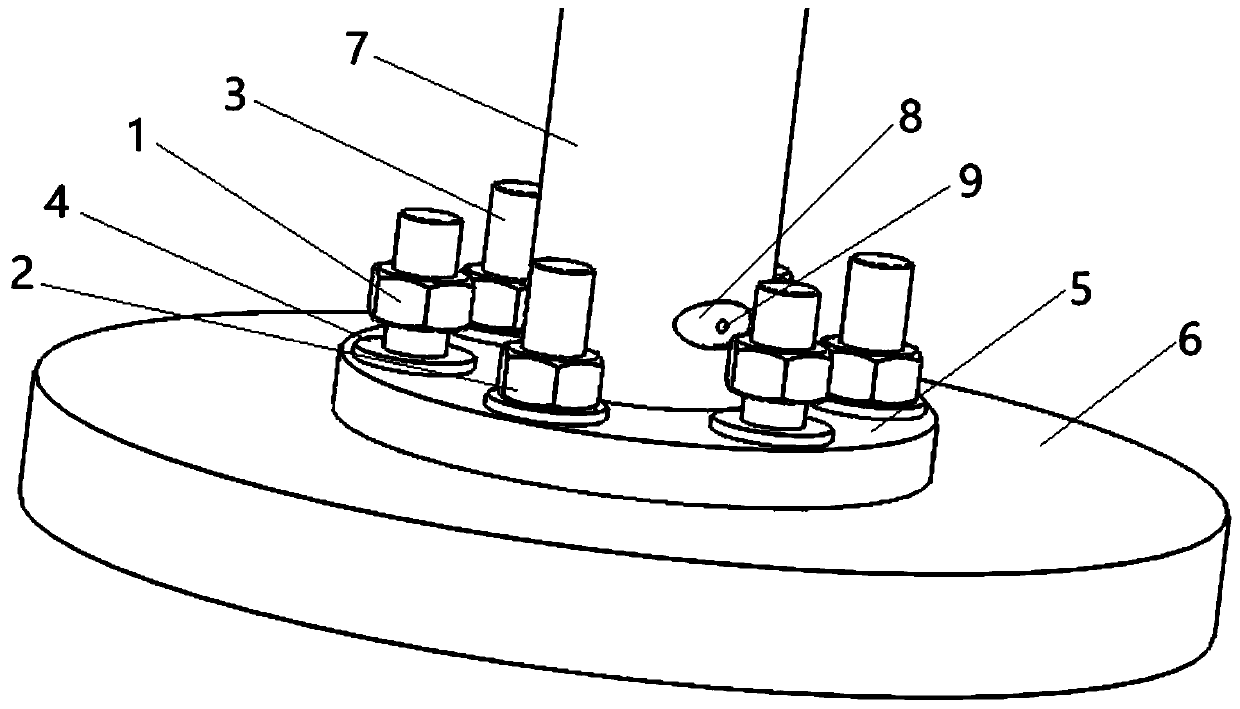

[0049] The installation form of the nuts and screws of the bridge base is generally as follows: Nut 1, nut 2 and other nuts are socketed and fixed on the ladder screw 3, the ladder screw 3 is installed on the screw mounting base 5, the ladder screw 3 and the screw mounting base There are gaskets 4 between the 5.

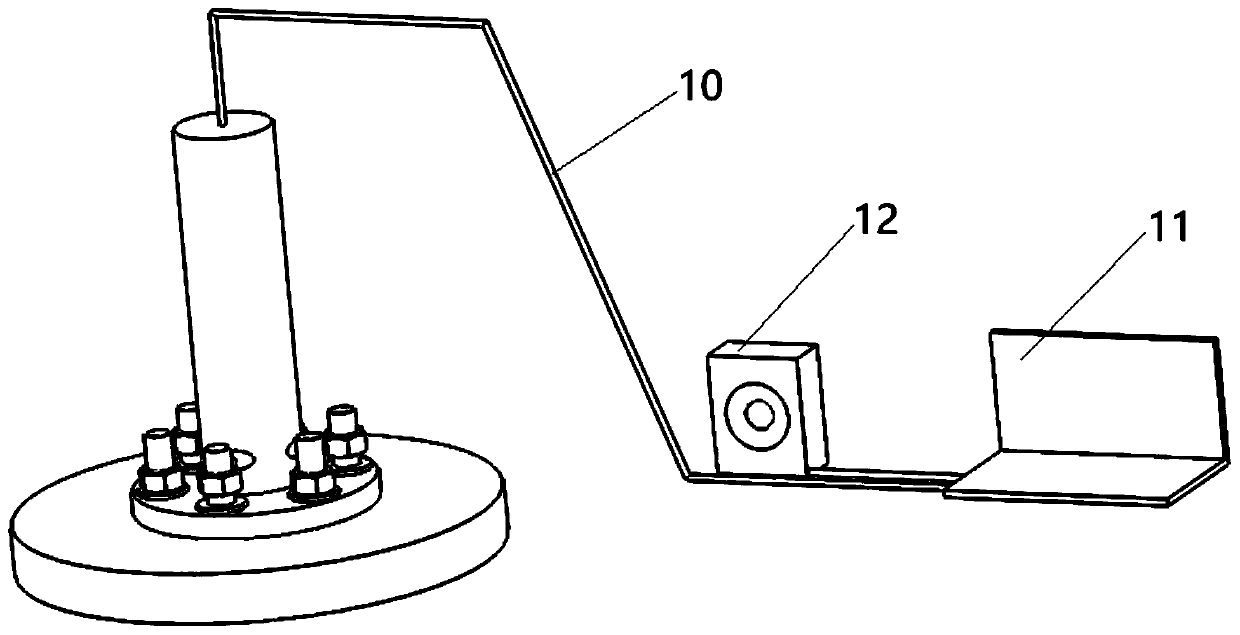

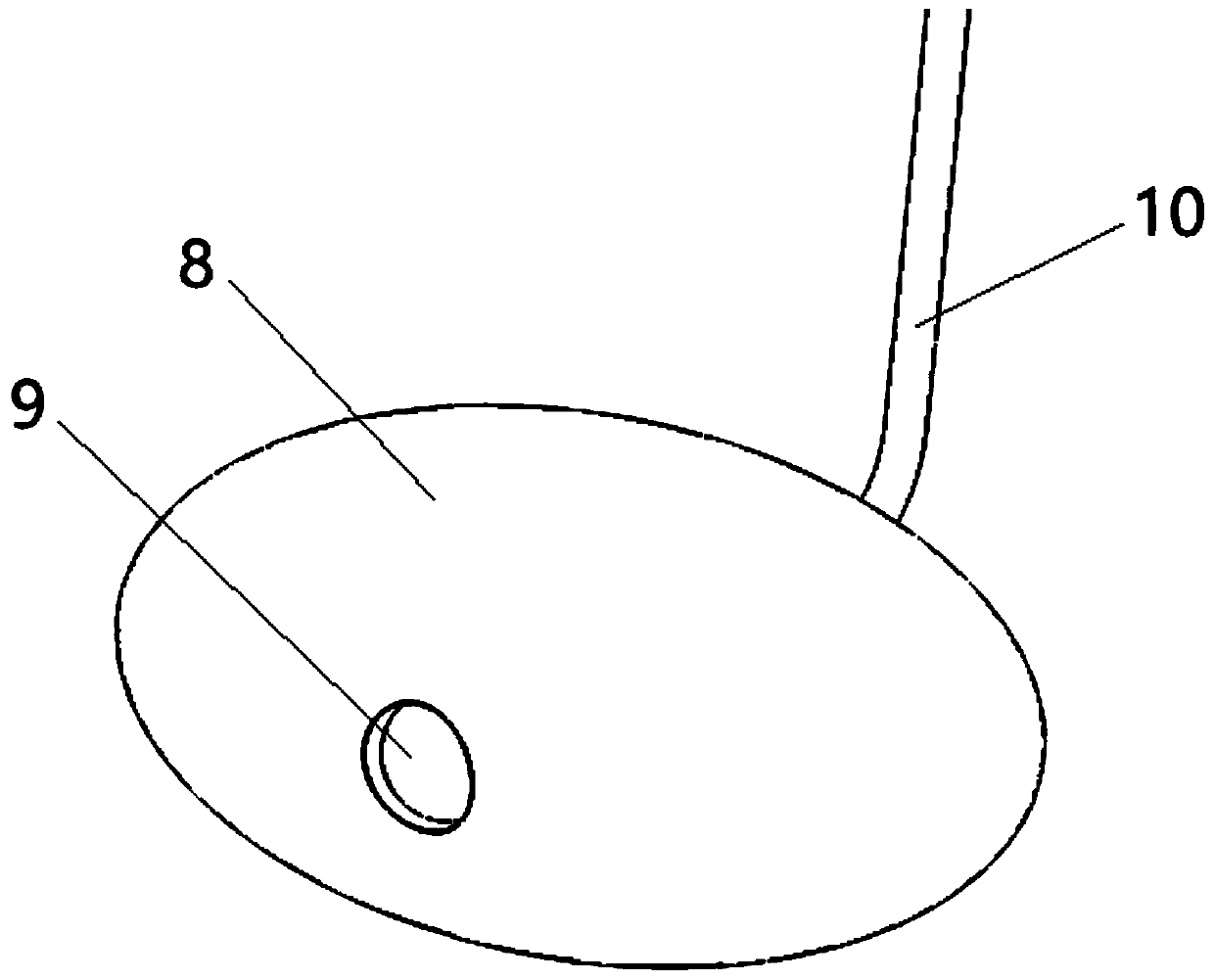

[0050] A multi-eye stereo vision detection device for loosening or cracking of nuts and screws at the base of a bridge, comprising a bionic clamshell frame 8 and a miniature camera 9; four bionic clamshells are evenly arranged and installed in the circumference of the lower part of the middle column 7 of the bridge base 6 Type frame 8, a miniature camera 9 is installed in each clam shell, the bionic clam shell is closed basically, and the structure of bionic clam shell can prevent wind, rainwater, and network cable and electric wire pass through from clam shell tail. Two adjacent miniature cameras form a pair of stereoscopic vision, and a small hole is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com