A Design Method of Control Loop Based on Cutoff Frequency

A technology of cut-off frequency and design method, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as low efficiency, difficulty in obtaining theoretical support, and heavy control loop design workload, and achieve good results. The effect of controlling quality and robustness, improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a method for designing a control loop based on a cut-off frequency, which is applicable to the design of a single-loop or multi-loop control loop for forward series proportional control, integral control or proportional-integral control, comprising the following steps:

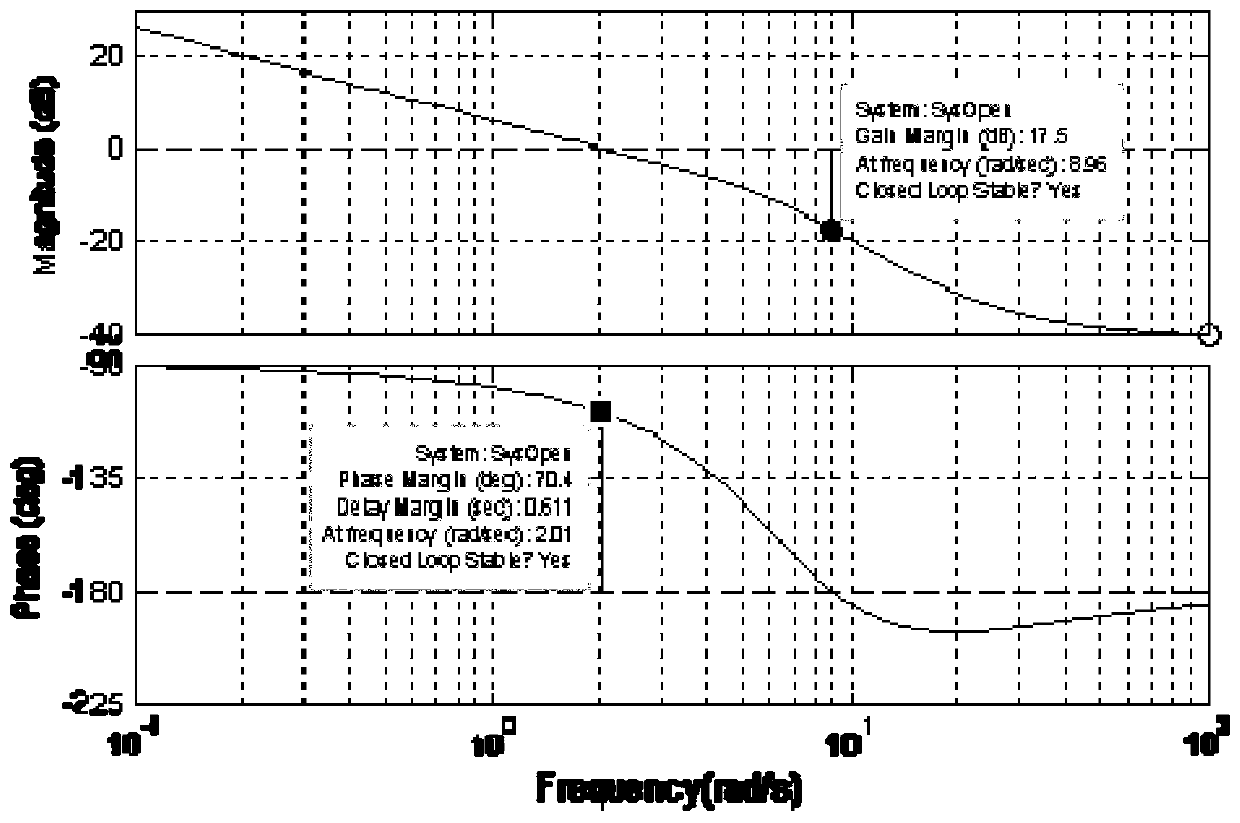

[0027] (1) Determine the cut-off frequency ω of the open-loop control loop according to the characteristics of the controlled object and the actuator and the rapidity requirements of the control system c , this ω c It is an important design index of the control loop, which can be regarded as the control loop bandwidth.

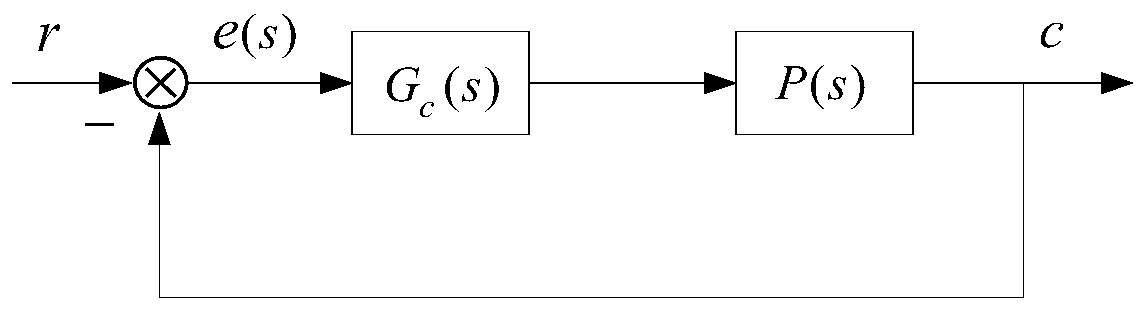

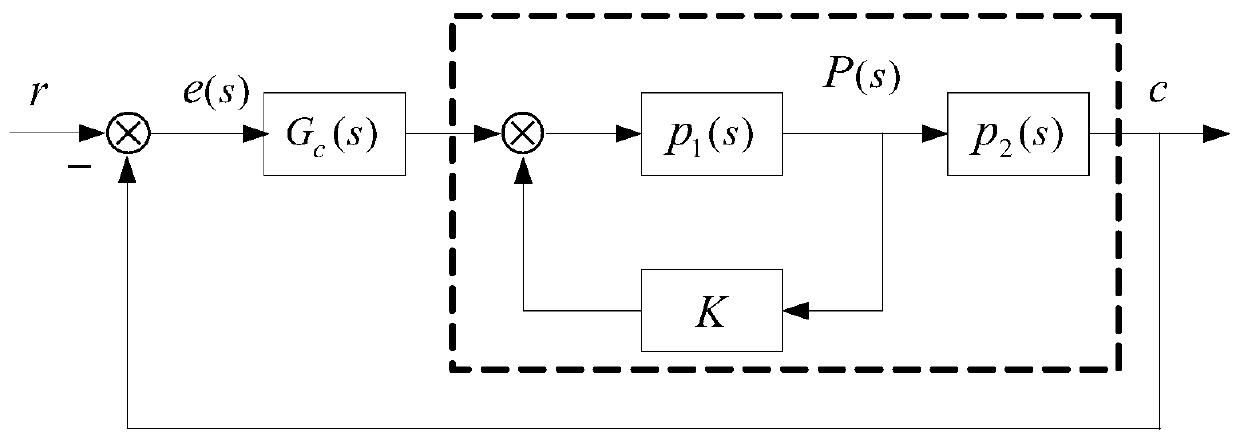

[0028] (2) if figure 1 As shown, the forward path controller G will be divided c Other control links other than (s) are equivalent to the generalized controlled object P(s), such as figure 2 As shown, if there are multiple control loops, it is necessary to equivalently transform the inner loop including the controlled object into a generalized controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com