Coke oven basement automatic inspection device

An automatic inspection and basement technology, which is applied to measuring devices, televisions, instruments, etc., can solve problems such as long manual inspection cycle, large safety hazards in production, and difficulty in inspection in place, so as to facilitate big data analysis and improve inspection The effect of improving efficiency and shortening the inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0017] Wherein the MCU processor model that the present invention uses is: STM32F103C8T6.

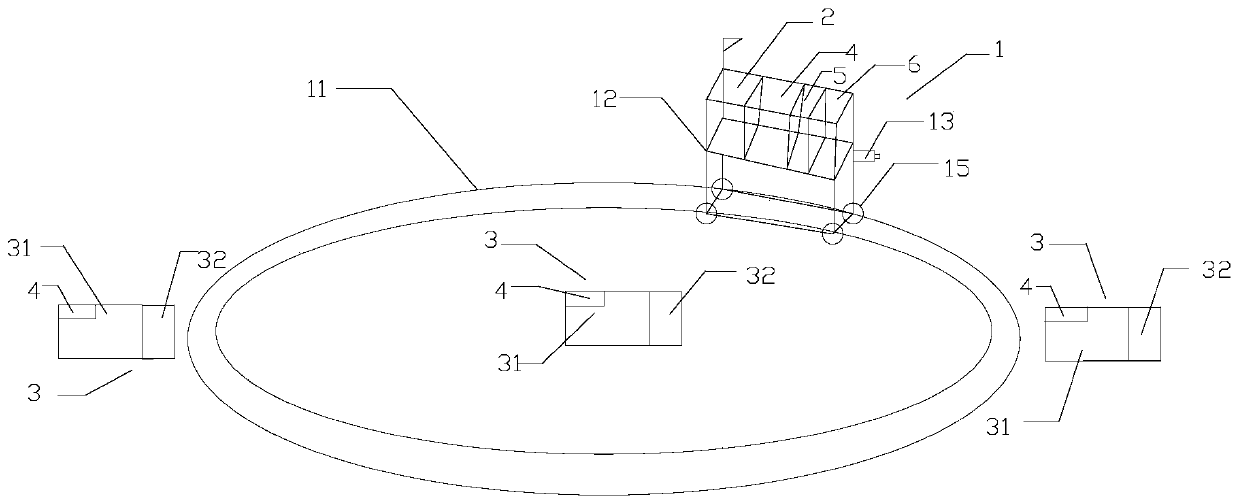

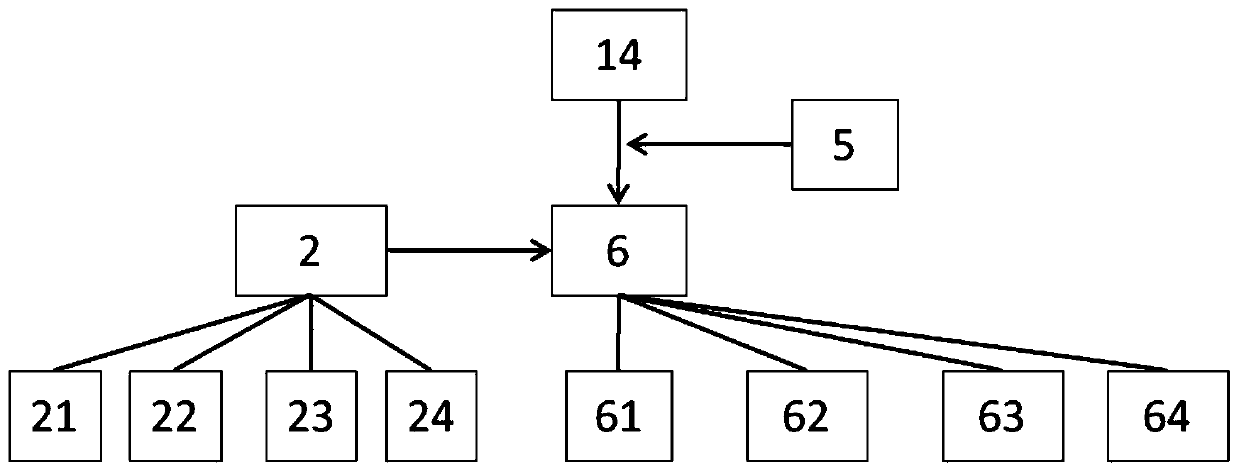

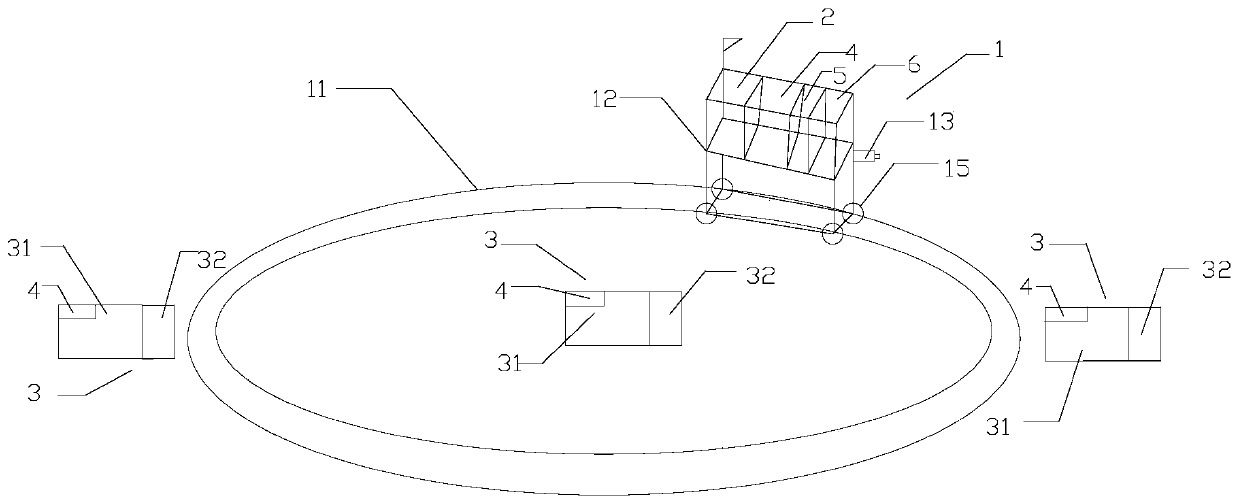

[0018] An automatic inspection device for a coke oven basement, including an inspection mobile unit 1, a detection unit 2, a charging station 3, a control unit 4, a wireless transceiver device 5, and a cloud server 6; the inspection mobile unit 1 includes a slide rail 11, Mobile trolley 12, driving device 13, position detection unit 14, the bottom front end surface of described mobile trolley 12, rear end surface all are provided with two groups of moving pulleys 15, and pulleys 15 are installed on the slide rail 11; Described slide rail 11 is wide 60-80cm zigzag closed path, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com