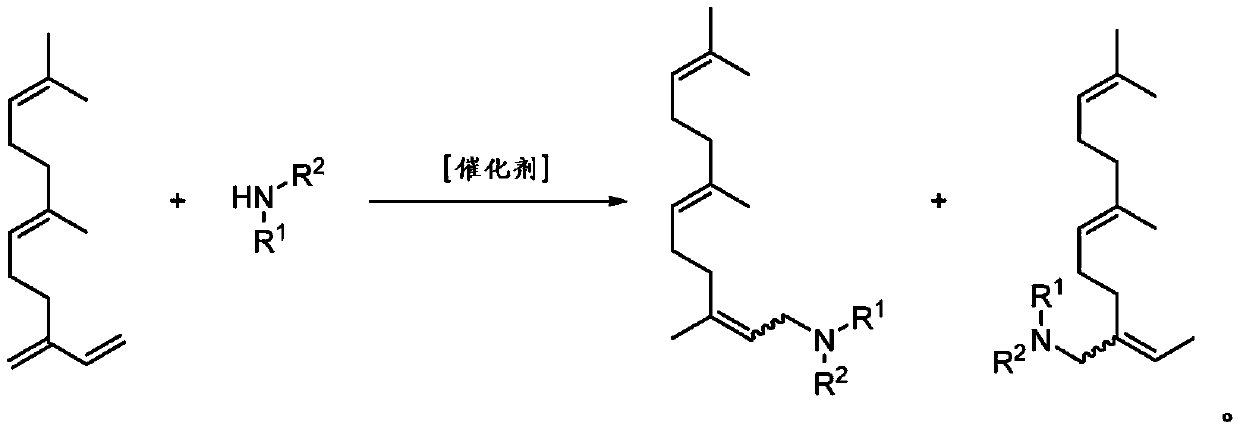

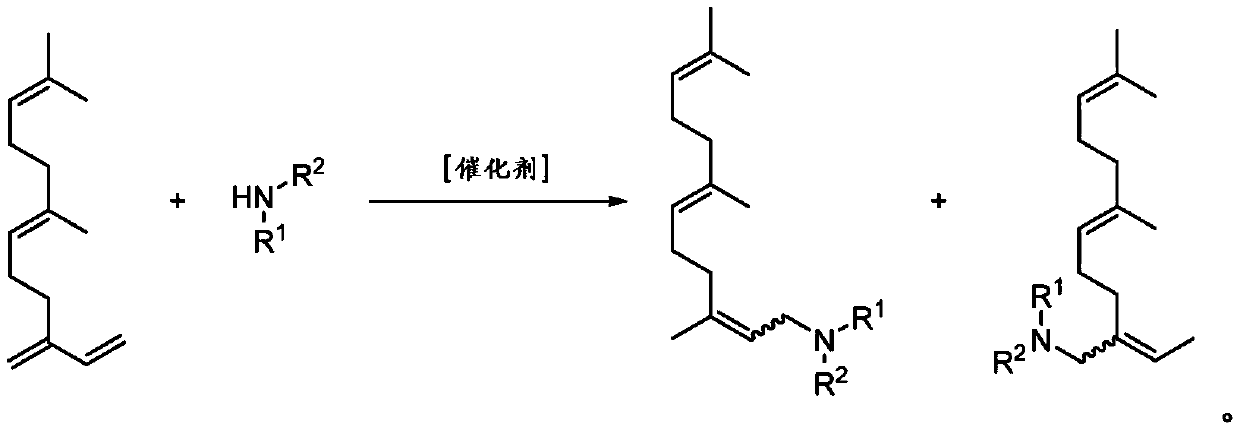

Amine derivatives of the beta-farnesene

A technology of farnesene and farnesamide, which is applied in the field of amine derivatives and can solve problems such as ineffective reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

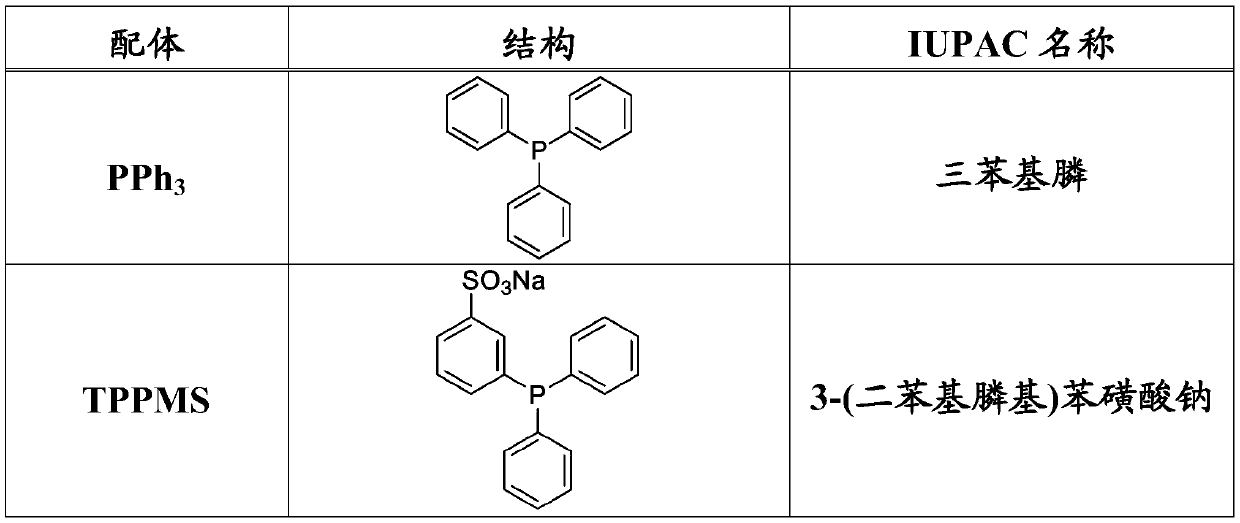

Method used

Image

Examples

Embodiment 1

[0069] Weigh 16.6 mg of Pd(hfacac) in a 25 mL steel autoclave 2 and 109.3 mg of DPPB and dissolved in 5 mL of DMF. Then 817.4 mg of β-farnesene and 296.9 mg of diethylamine were added. The reactor was closed and loaded with argon pressure of 5 bar.

[0070] The reactor was heated at 100 °C for 5 h and stirred at 500 rpm by means of a magnetic stirrer. To terminate the reaction, the reactor was cooled to room temperature and then argon was carefully vented.

[0071] The obtained reaction solution was freed of solvent under vacuum and the product was purified by column chromatography. 863.2 mg (78%) of the hydroaminated product were obtained.

Embodiment 2

[0073] Weigh 10.6 mg of Pd(tfa) in a 25 mL steel autoclave 2 and 137.8 mg of DPEPhos and dissolved in 5 mL of methanol. Then 817.7 mg of β-farnesene and 297.1 mg of diethylamine were added. The reactor was closed and loaded with argon pressure of 5 bar.

[0074] The reactor was heated at 100 °C for 5 h and stirred at 500 rpm by means of a magnetic stirrer. To terminate the reaction, the reactor was cooled to room temperature and then argon was carefully vented.

[0075] The obtained reaction solution was freed of solvent under vacuum and the product was purified by column chromatography. 960.4 mg (89%) of the hydroaminated product were obtained.

Embodiment 3

[0077] Weigh 10.5 mg of Pd(tfa) in a 25 mL steel autoclave 2 and 137.7 mg of DPEPhos and dissolved in 5 mL of anisole. Then 816.8 mg of β-farnesene and 516.6 mg of dibutylamine were added. The reactor was closed and loaded with argon pressure of 5 bar.

[0078] The reactor was heated at 100 °C for 5 h and stirred at 500 rpm by means of a magnetic stirrer. To terminate the reaction, the reactor was cooled to room temperature and then argon was carefully vented.

[0079] The obtained reaction solution was freed of solvent under vacuum and the product was purified by column chromatography. 960.8 mg (72%) of the hydroaminated product were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com