Overflow device for wet lithium ion battery separator extraction equipment

A lithium-ion battery and extraction equipment technology, applied in the field of overflow devices, can solve problems such as restricting the speed-up and cost-reduction of wet-process diaphragm production lines, limiting the solubility of extractants, and hidden dangers of environmental safety and security, so as to reduce the risk of environmental pollution, Save material energy consumption and reduce the effect of back mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further elaborated below in conjunction with the embodiments and the accompanying drawings.

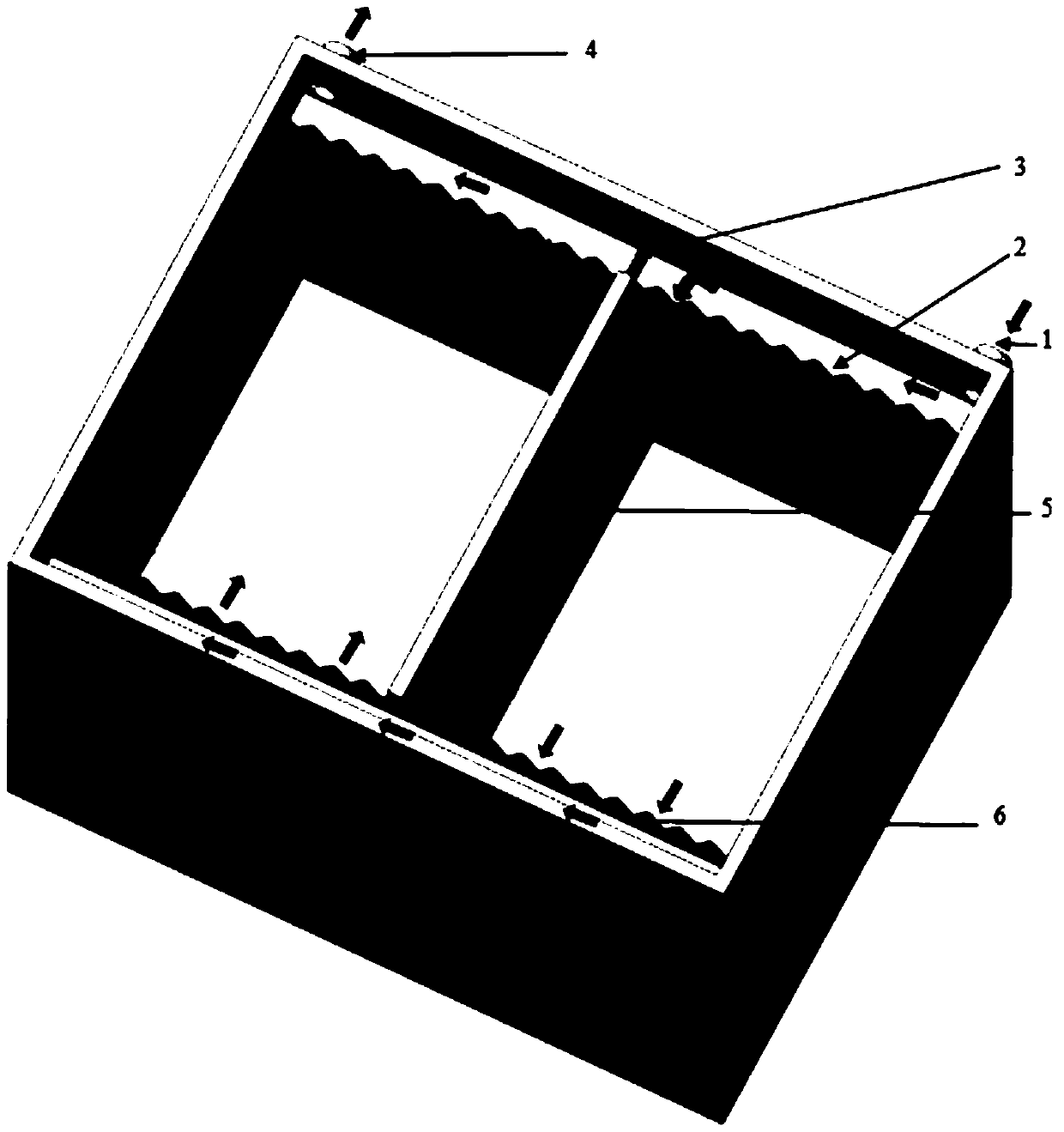

[0024] This embodiment provides an overflow device for wet lithium-ion battery diaphragm extraction equipment, such as figure 2 As shown, it includes two parts: a flow guiding device and a flow blocking device. The diversion device part includes the extraction agent overflow pipe (1 in the figure is the inlet, 4 is the outlet), an overflow tank (2 in the figure is the driving side, and 6 is the operation side), and the choke device part includes the overflow tank choke Plate 3, dividing baffle plate 5 in the extraction tank.

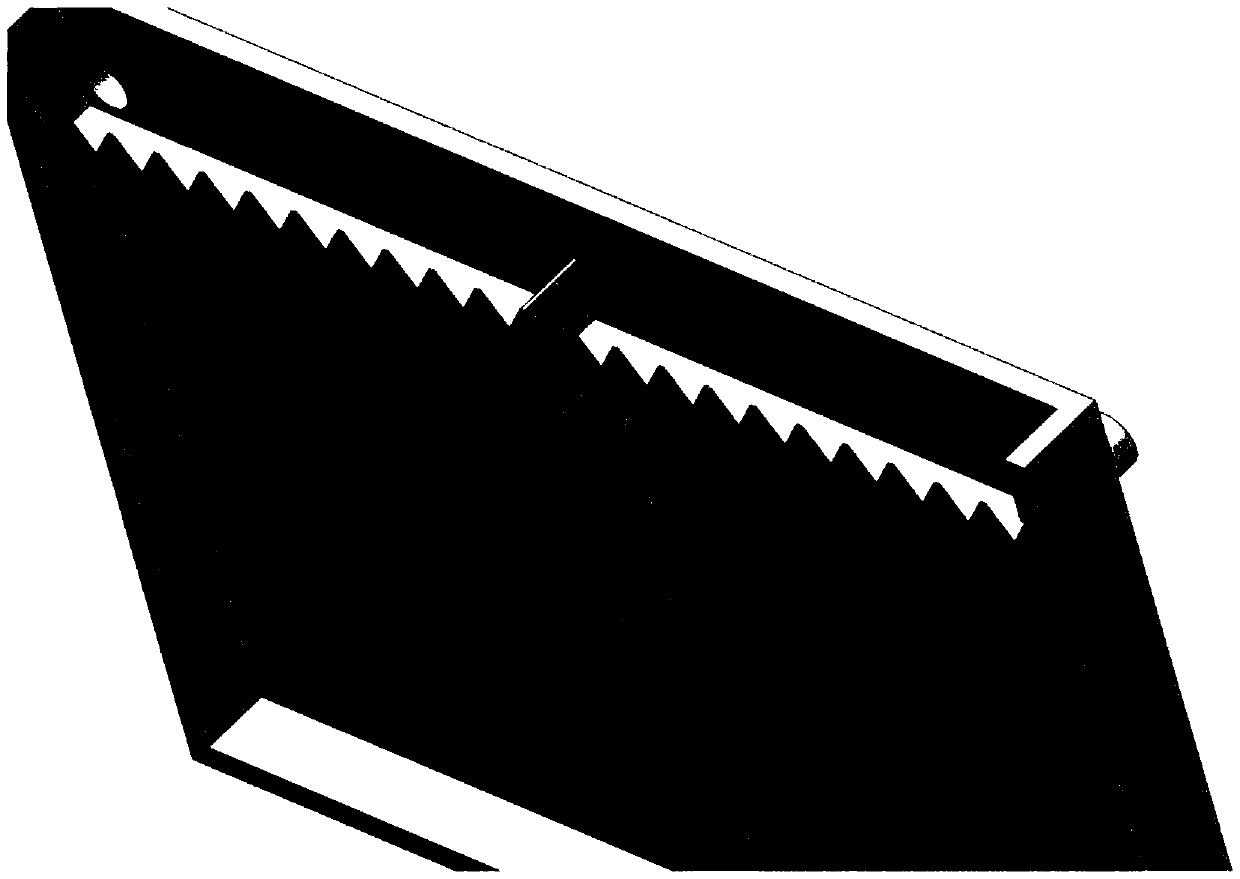

[0025] Wherein, the function of the extraction agent overflow pipe (1 and 4 in the figure) is to conduct the extraction agent between two adjacent extraction tanks in an overflow manner. In this embodiment, an overflow port is respectively cut at the inlet and outlet of the driving side of the extraction tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com