Single-side superhydrophobic and single-side hydrophilic Janus type micro-nano composite fiber film and preparation method thereof

A composite fiber membrane, micro-nano technology, applied in fiber treatment, chemical instruments and methods, filament/wire forming, etc., can solve the problems that hinder the practical application of materials, complex preparation methods, single function, etc., and achieve good separation effect, The effect of simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

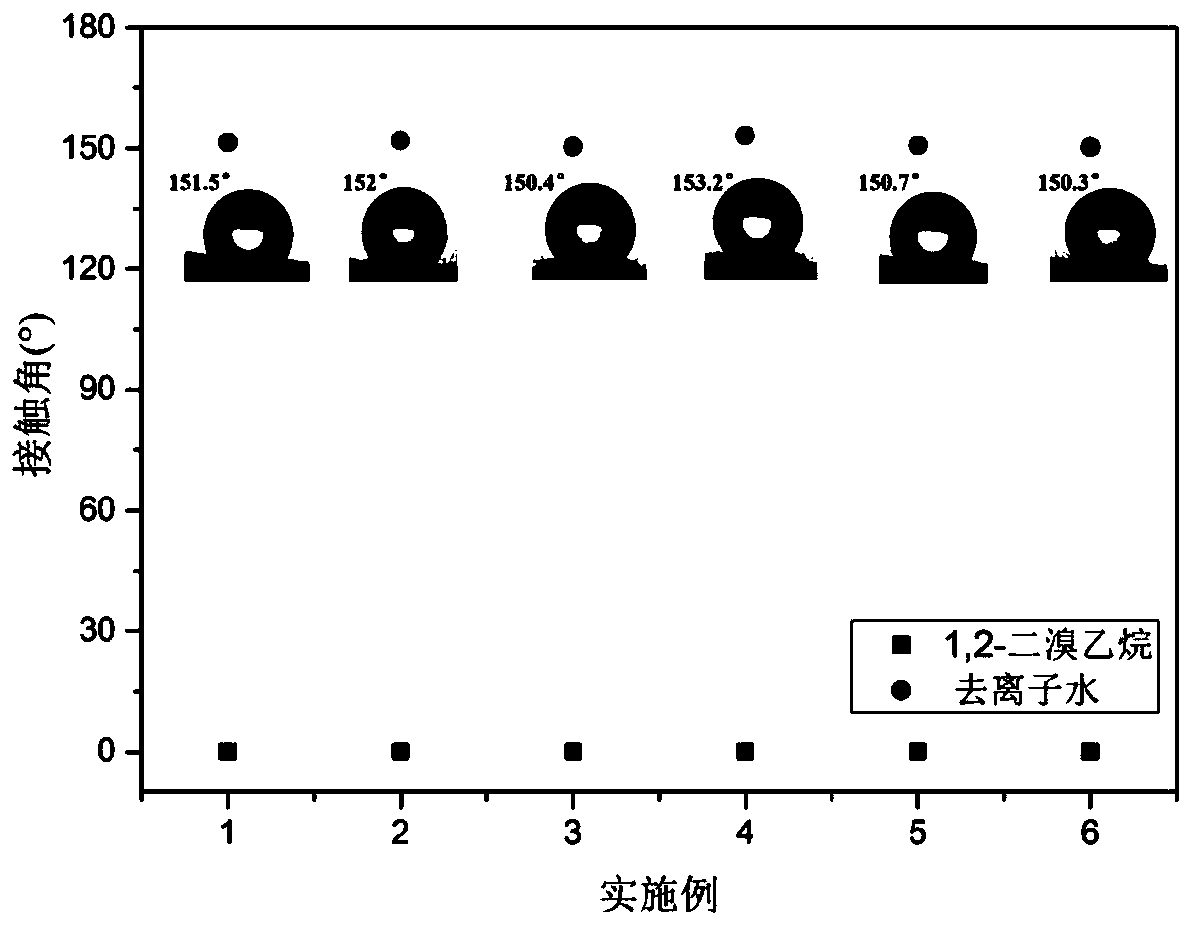

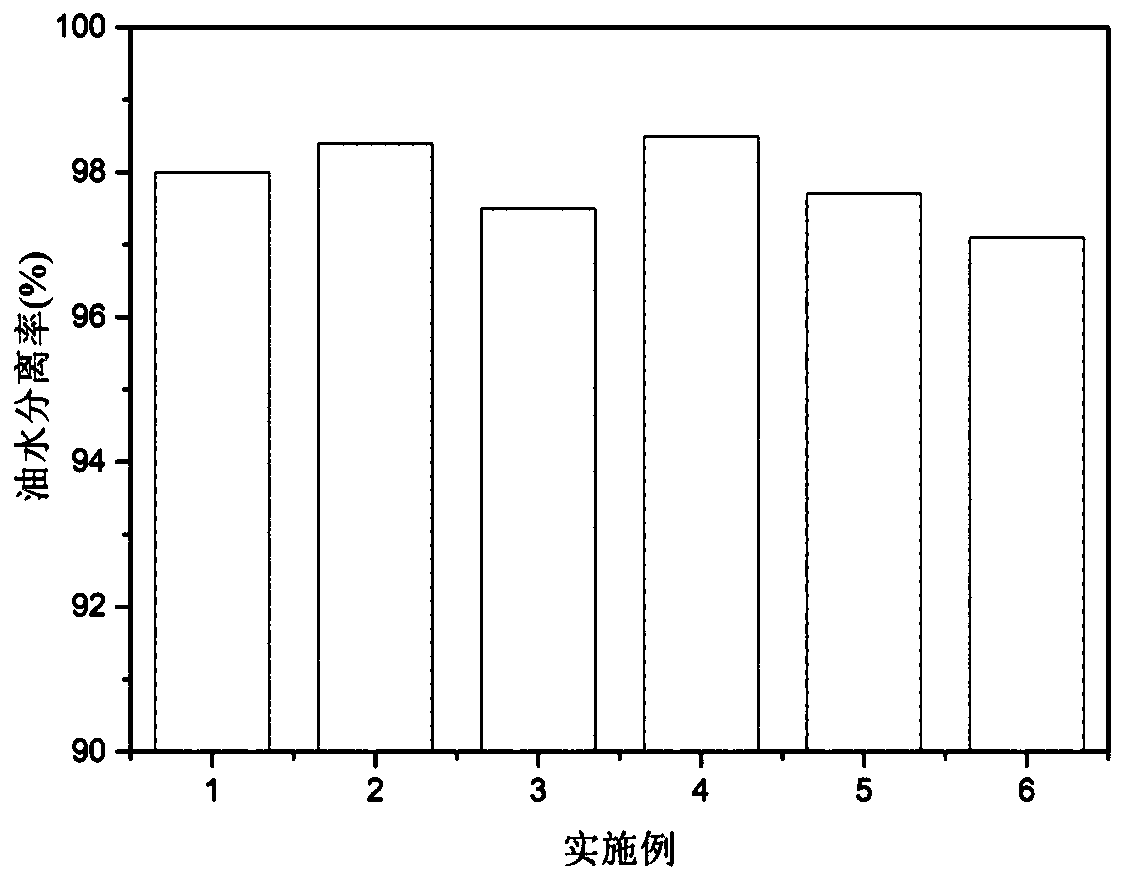

Examples

Embodiment 1

[0036] A method for preparing a Janus-type micro-nano composite fiber membrane with superhydrophobic and hydrophilic on one side, the specific steps are as follows:

[0037](1) Prepare a CA spinning solution with a mass fraction of 19%, the solvent and the ratio are acetone: DMAC = 7:3, place it on a heating magnetic stirrer at 55°C and stir for 12 hours, inject it into a syringe and spin it on an electrospinning machine , the spinning voltage is 13KV, the receiving distance is 20cm, and the injection speed is 0.05mm / min;

[0038] (2) Prepare a PVDF spinning solution with a mass fraction of 12%, the solvent and the ratio are acetone:DMF = 6:4, place it on a heating magnetic stirrer at 55°C and stir for 12 hours, then perform centrifugal spinning, and the diameter of the spinning head is 0.4 mm, the spinning speed is 10000rpm / min;

[0039] (3) Soak the spun PVDF fiber membrane in the MPS hydrophobically modified SiO 2 Put in the sol-gel solution for 20 minutes, let it dry at ...

Embodiment 2

[0042] A method for preparing a Janus-type micro-nano composite fiber membrane with superhydrophobic and hydrophilic on one side, the specific steps are as follows:

[0043] (1) Prepare a CA spinning solution with a mass fraction of 19%, the solvent and the ratio are acetone: DMAC = 7:3, place it on a heating magnetic stirrer at 55°C and stir for 12 hours, inject it into a syringe and spin it on an electrospinning machine , the spinning voltage is 13KV, the receiving distance is 20cm, and the injection speed is 0.05mm / min;

[0044] (2) Prepare a PVDF spinning solution with a mass fraction of 11%, the solvent and the ratio are acetone: DMF = 6:4, place it on a heating magnetic stirrer at 55°C for 12 hours and then perform centrifugal spinning. The diameter of the spinning head is 0.4 mm, the spinning speed is 8000rpm / min;

[0045] (3) Soak the spun PVDF fiber membrane in the MPS hydrophobically modified SiO 2 Put in the sol-gel solution for 20 minutes, let it dry at room temp...

Embodiment 3

[0048] A method for preparing a Janus-type micro-nano composite fiber membrane with superhydrophobic and hydrophilic on one side, the specific steps are as follows:

[0049] (1) Prepare a CA spinning solution with a mass fraction of 18%, the solvent and the ratio are acetone:DMSO = 7:3, place it on a heating magnetic stirrer at 55°C and stir for 12 hours, inject it into a syringe and spin it on a centrifugal spinning machine , the diameter of the spinning head is 0.4mm, and the spinning speed is 8000rpm / min;

[0050] (2) Prepare a PVDF spinning solution with a mass fraction of 11%, the solvent and the ratio are acetone: DMF = 6:4, place it on a heating magnetic stirrer at 55°C for 12 hours and then carry out electrospinning, the spinning voltage is 13KV, The receiving distance is 20cm, and the injection speed is 0.05mm / min;

[0051] (3) Soak the spun PVDF fiber membrane in the MPS hydrophobically modified SiO 2 Put in the sol-gel solution for 20 minutes, let it dry at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap