A multipurpose chemical vapor deposition device

A chemical vapor deposition, multi-purpose technology, applied in the field of chemical vapor deposition equipment, can solve the problems of slow response speed, inconvenient adjustment and control, structural damage, etc., to achieve the effect of wide application, high thermal efficiency and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings.

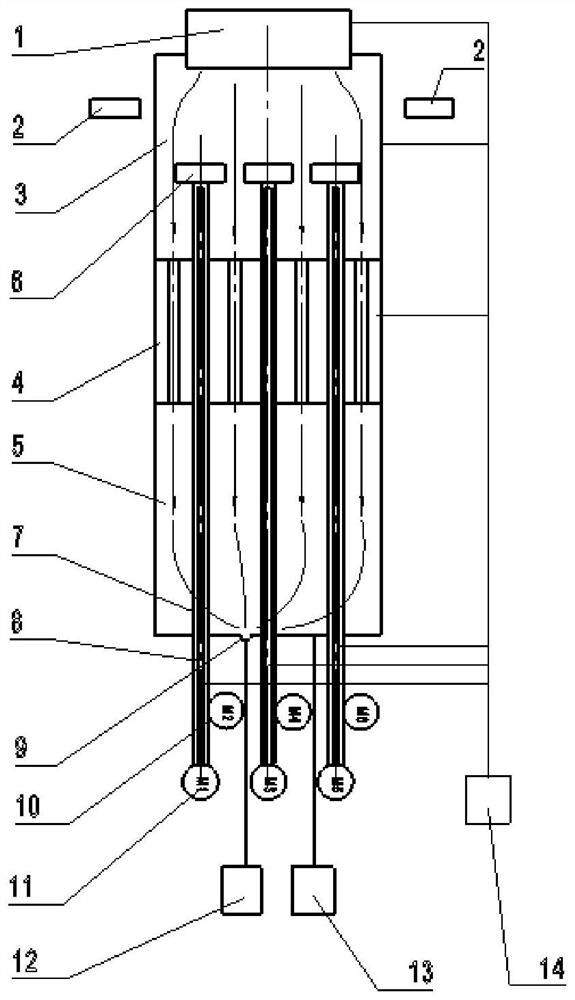

[0021] The multipurpose chemical vapor deposition device structure of the present invention is as figure 1 As shown, the top of the device is a plasma source 1, and a heat exchanger 4 is arranged in the middle of the inner cavity of the device, and the heat exchanger 4 divides the inner cavity of the device into two parts: an upper deposition reaction chamber 3 and a lower gas collection chamber 5 The middle part of the heat exchanger 4 is provided with a through hole that can communicate with the deposition reaction chamber 3 and the gas collection chamber 5; the deposition reaction chamber 3 is provided with a deposition platform 6, and the deposition platform 6 is connected below the deposition platform The drive shaft 7, the drive shaft 7 of the deposition table passes downwards through the two parts of the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com