High-precision multi-cone deep hole detection device and detection method

A detection device, high-precision technology, applied in the direction of measuring device, mechanical measuring device, mechanical device, etc., to achieve the effect of easy processing, low manufacturing cost and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

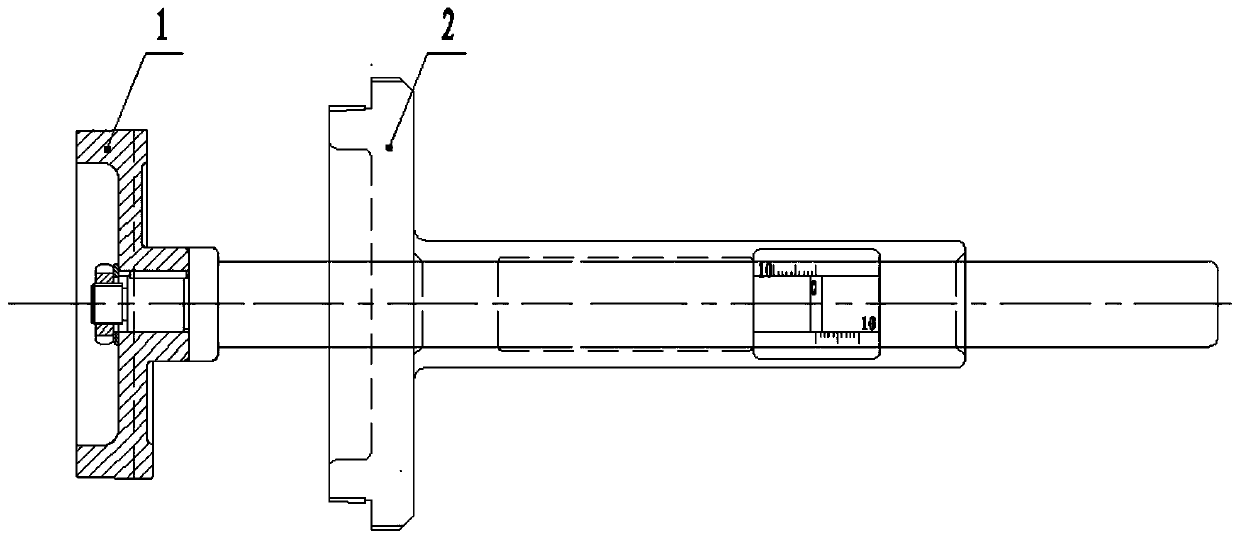

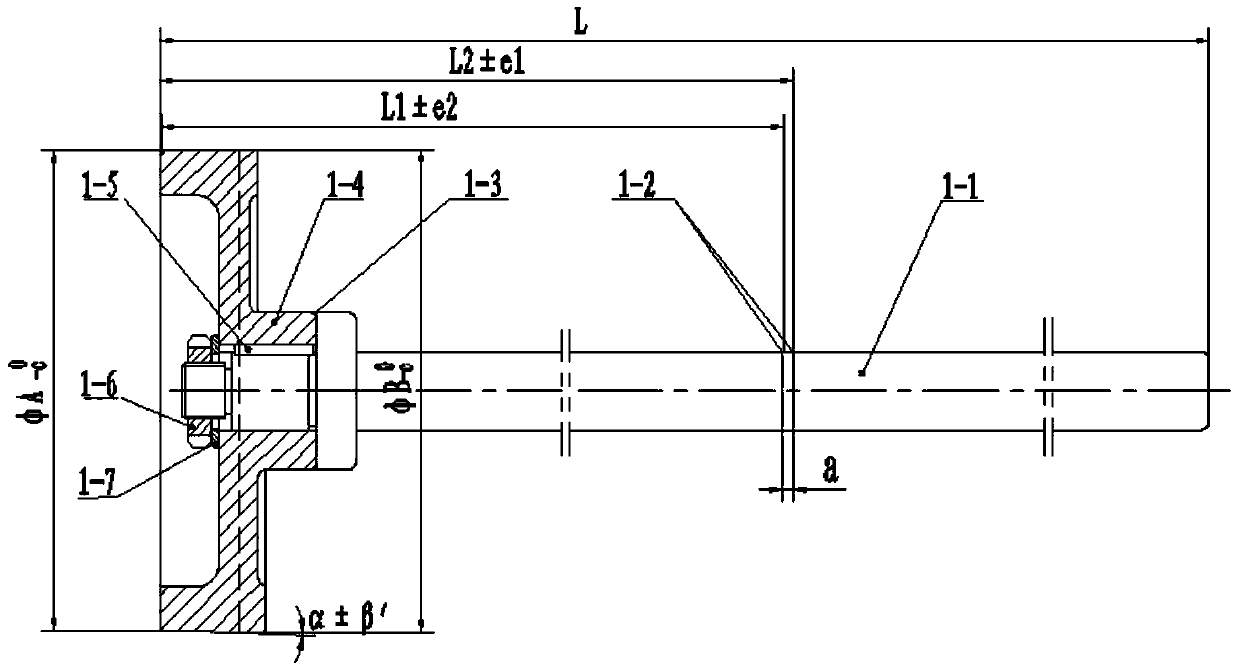

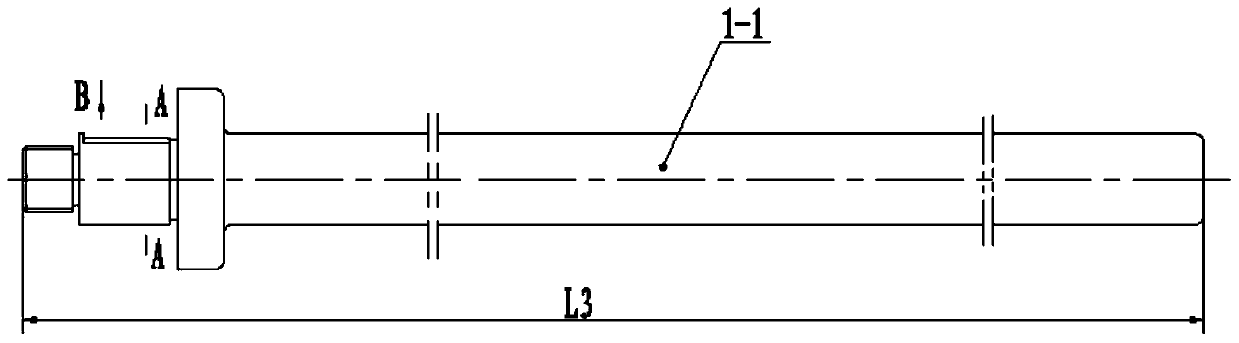

[0055] Such as figure 1 As shown, the detection device of the present invention includes two major components: an indicator 2 and a complete set of gauges 1 . In actual use, the complete set of gauges 1 is in contact with the inner taper hole of the tested part 3 (see Figure 9 ) and the axial displacement is accurately reflected on the indicator 2 in a ratio of 1:1 to realize the acquisition of detection data.

[0056] The indicator 2 is matched with the complete set of gauge 1 through the gap between the hole and the shaft, and it is ensured that the indicator 2 can move smoothly on the handle shaft 1-1 of the complete set of gauge 1 .

[0057] When in use, when the "0" position of the coordinate engraved line on the indicator 2 falls between the two engraved lines on the complete set of gauge 1, it can be judged that the taper size accuracy, shape accuracy, and position accuracy are qualified; the "0" position of the coordinate engraved line on the indicator 2 When it fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com