Automobile instrument automatic detection device and method based on machine vision

An automatic detection and automotive instrumentation technology, applied in the field of image processing, can solve the problems of rising labor costs, hidden dangers of manual operation, and low degree of automation, so as to improve the degree of automation and efficiency, reduce labor costs, and avoid safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

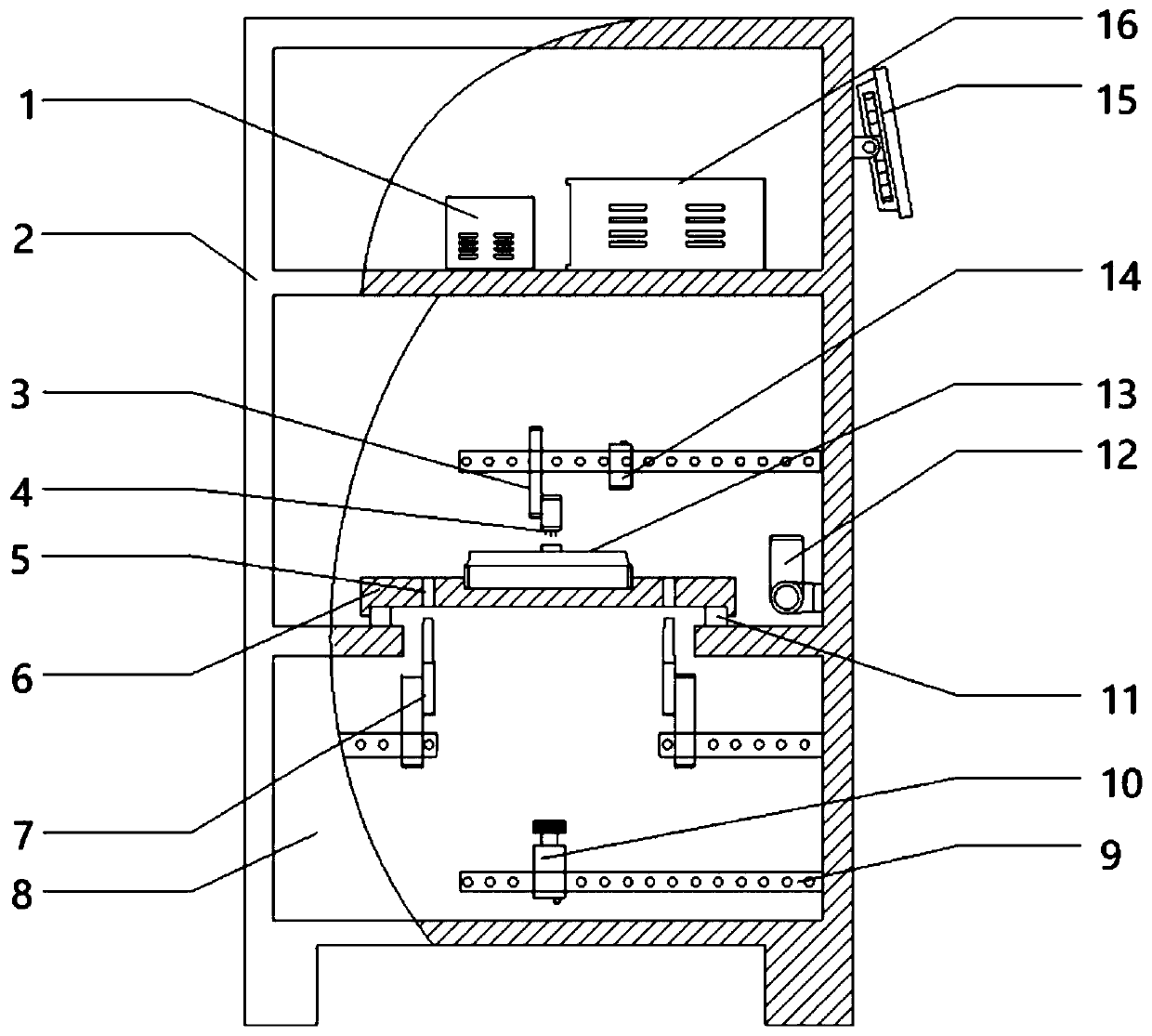

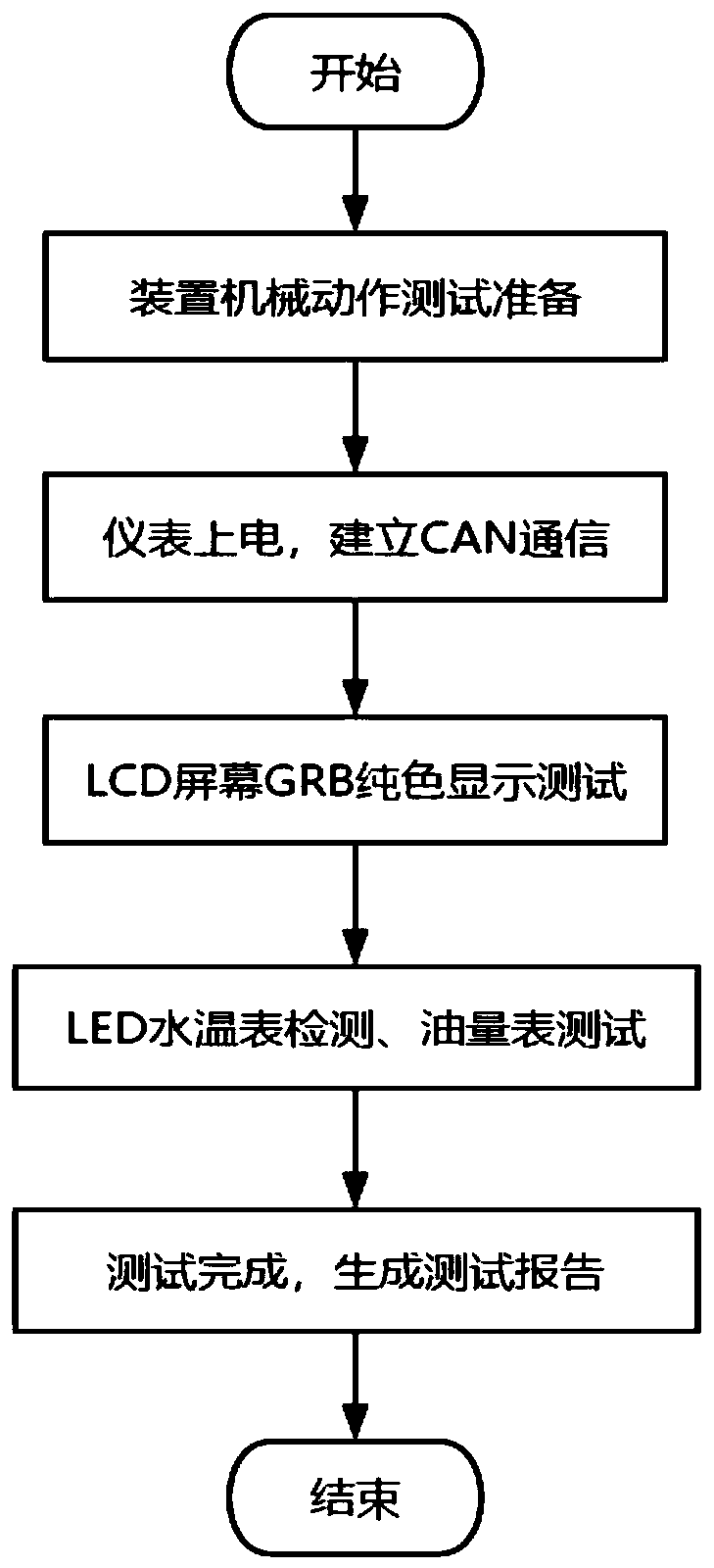

[0058] An automatic detection device for automobile instrument based on machine vision technology is attached figure 1 As shown, it includes industrial computer, test system cabinet, transmission positioning unit, and image acquisition visual components.

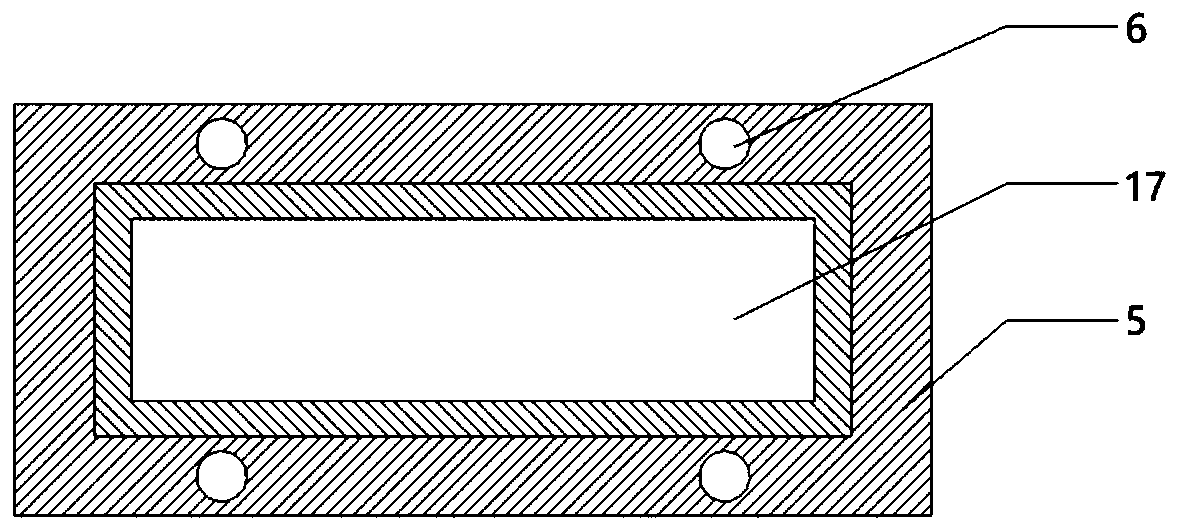

[0059] The cabinet 2 is used to place various test equipment and is divided into upper, middle and lower floors. The upper layer places the power supply 1, the industrial computer and its related accessories, and the industrial computer is connected to the display 15 for displaying the content of the detection; the middle layer places the mechanical movement mechanism, including the clamp, the blocking plate 12, the positioning pillar 7, the carrier plate 6, and the instrument panel 13; the lower layer Place the camera and its fixed stand 9.

[0060] The image capture visual components include:

[0061] The industrial camera 10 adopts a large horizontal image MER-G-P-500 ultra-small industrial digital camera with a resolut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap