Sample manufacturing method for representing blade body performance of thin-walled blade casting

A manufacturing method and thin-walled technology, which are applied in the preparation of test samples, sampling devices, etc., can solve the problem of inability to accurately characterize the tissue characteristics of thin-walled leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

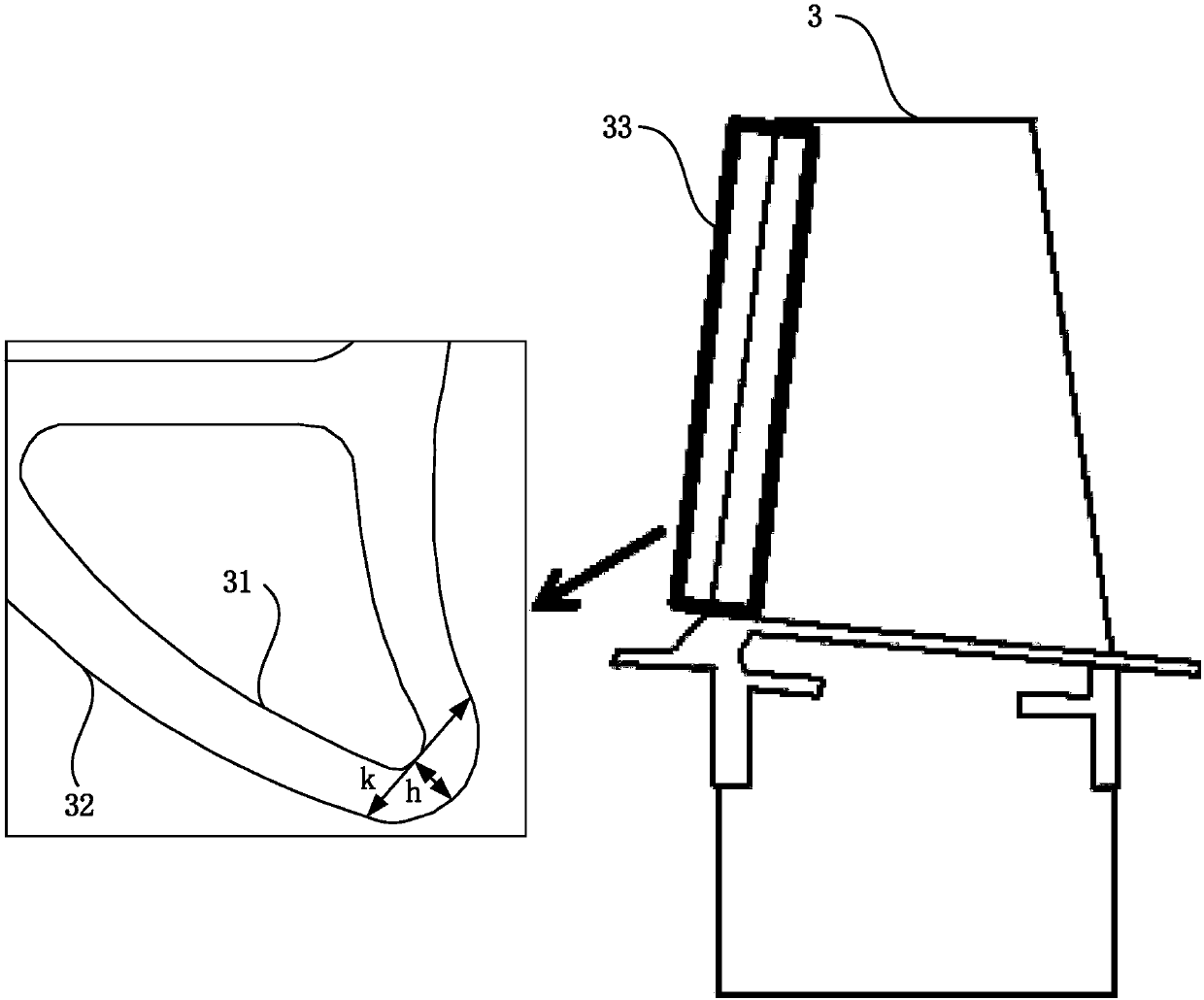

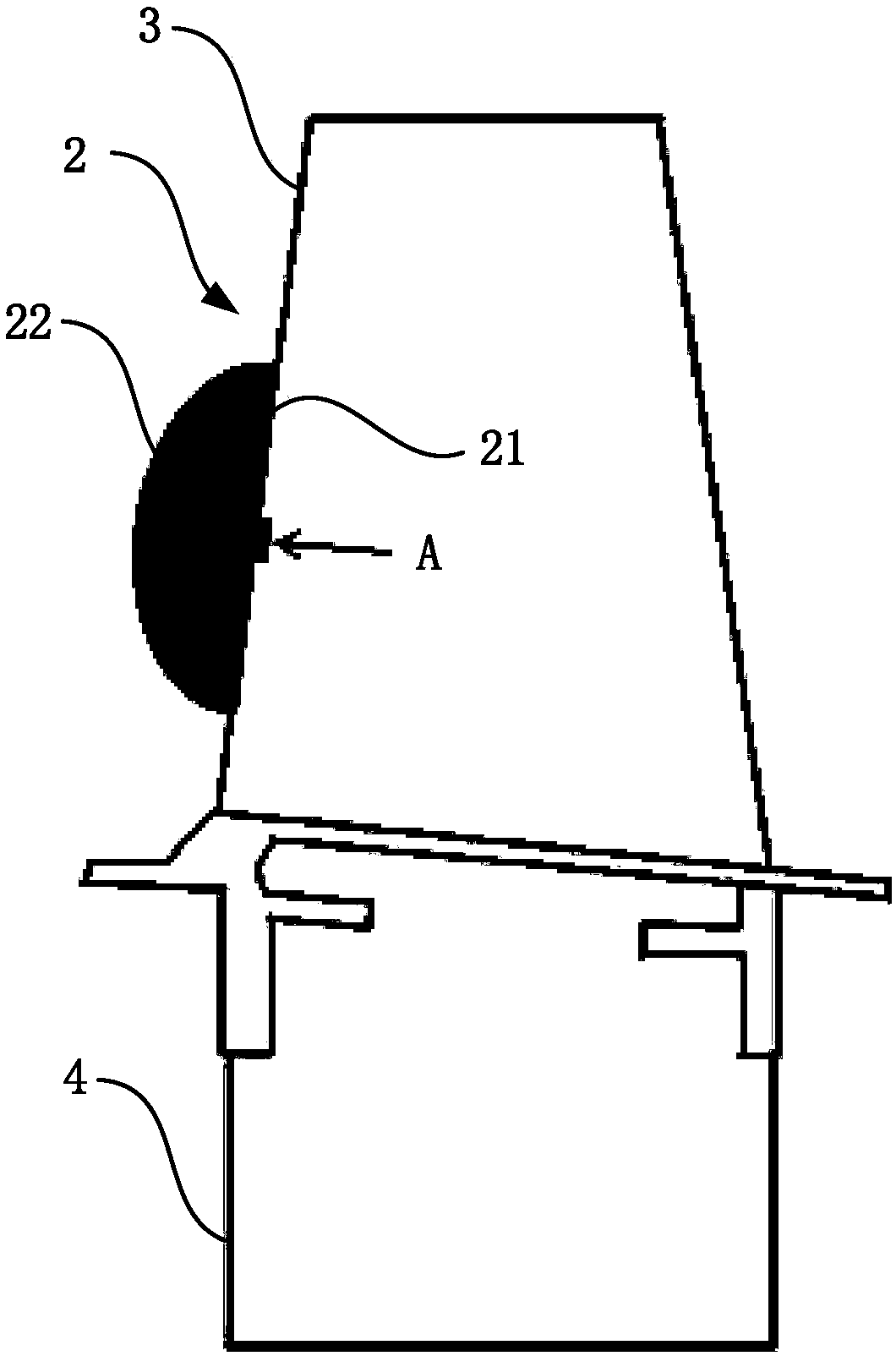

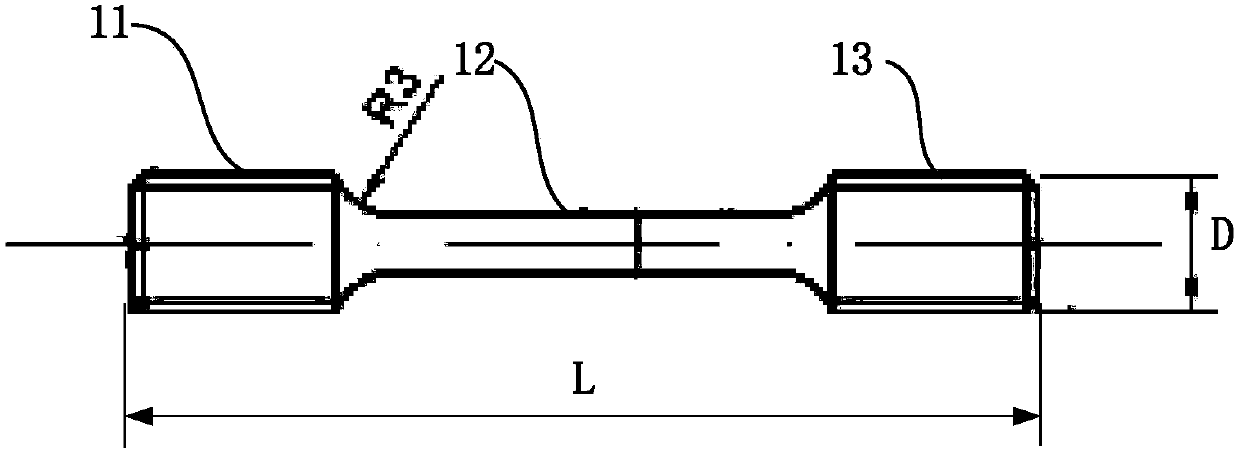

[0066] Embodiment 1: Take thin-walled blades as moving blades as an example. First, select the part that needs to be sampled from the airfoil (single crystal nickel-based superalloy turbine working blade), and then designate the position of the air inlet edge 80mm from the bottom of the tenon as the performance test point (such as Figure 4 ), the test location is usually selected comprehensively considering the temperature and stress of the working condition. According to the largest diameter of test specimen 1 (eg image 3 diameter of 6mm), length (such as image 3 40mm), and the wall thickness h of the intake side (such as figure 1 1mm), thicken the inlet edge of the thin-walled blade with the selected test point A as the center. The principles of thickening are as follows:

[0067] 1. The outer surface 32 is thickened, and the inner surface 31 remains unchanged;

[0068] 2. The position of the thickened edge should be smoothly transitioned, Figure 4 R1 and R2 should...

Embodiment 2

[0072] Embodiment 2: firstly select the part (equiaxed nickel-based superalloy turbine working blade) that needs to be sampled from the airfoil, and then designate the position of the inlet edge at the 80mm distance from the tenon bottom as the performance test point (such as Figure 4 ), the test location is usually selected comprehensively considering the temperature and stress of the working condition. According to the maximum diameter of the test specimen (1) (eg image 3 The diameter of 6mm), length (such as image 3 40mm), and the wall thickness h of the intake side (such as figure 1 1mm), and the position of the inlet edge of the blade is thickened with the selected test point as the center. The principles of thickening are as follows:

[0073] 1. The outer surface 32 is thickened, and the inner surface 31 remains unchanged;

[0074] 2. The position of the thickened edge should be smoothly transitioned, Figure 4 R1 and R2 should be controlled within R0.5-R3.0.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com