Phased array microwave imaging non-destructive detecting device and method

A technology of non-destructive testing and microwave imaging, which is applied in the direction of using microwave flaw detection, can solve the problems of lack of non-destructive testing equipment and methods, high-energy ray non-destructive testing, etc., and achieve the effect of high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

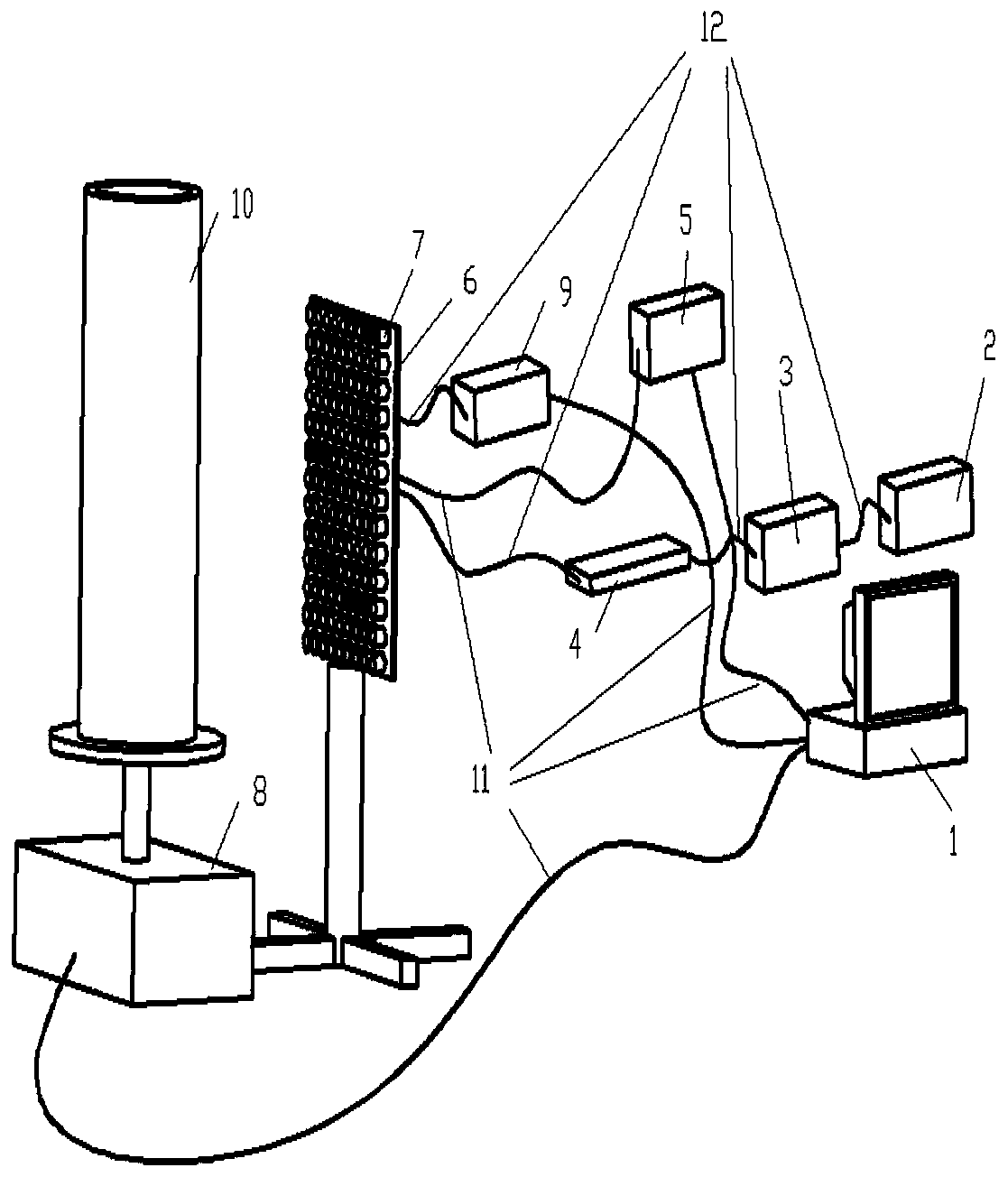

[0069] as attached figure 1 As shown, a microwave phased array nondestructive testing device is mainly composed of a computer (1), testing software, microwave source (2), power amplifier (3), power divider (4), controller (5), array antenna (6), feeder (12), signal acquisition and processor (9), positioner (8), etc., is characterized in that: the detection software is installed in a computer, and the size range of the workpiece to be measured can be set in the detection software Or three-dimensional shape model, the distance and orientation between the array antenna reference and the workpiece reference, microwave frequency and power, scanning frame rate and other parameters are used to control the scanning of the workpiece; the detection software is read from the computer board by the The collected signal can display the scanning image during the non-destructive testing process;

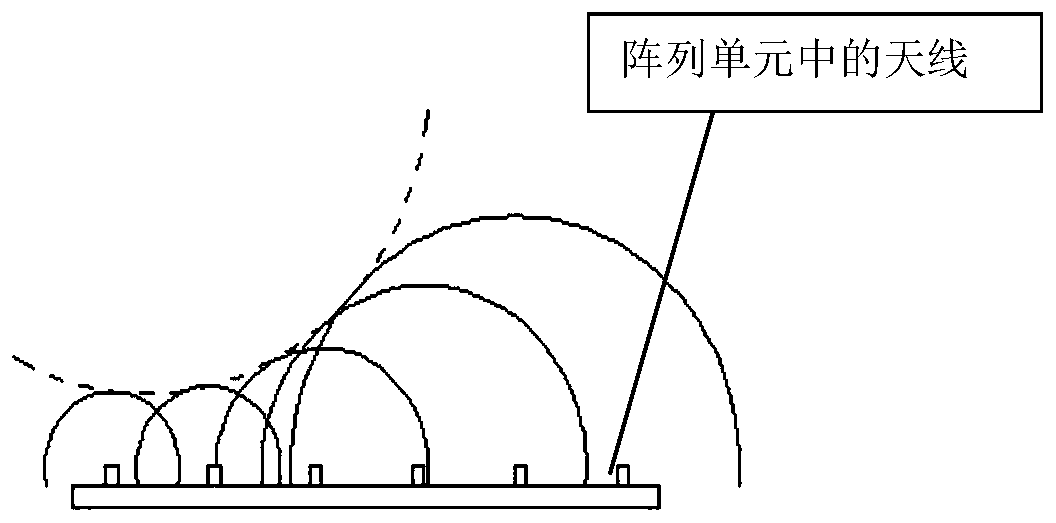

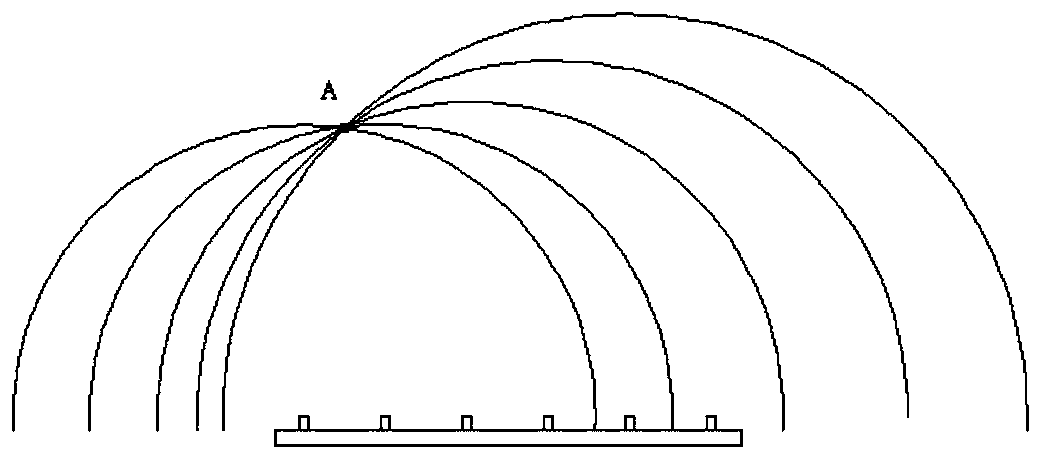

[0070] The microwave phased array non-destructive testing device controls the phase of the micr...

Embodiment 2

[0082] A phased array microwave imaging nondestructive testing device, mainly composed of computer, testing software, microwave source, power amplifier, power divider, controller, array antenna, feeder, signal acquisition and processor, positioner, etc., its features in:

[0083] The detection software is installed in a computer, and parameters such as the size of the measured workpiece, the microwave frequency, and the scanning frame rate are stored in the detection software to control the scanning of the workpiece by the software;

[0084] The computer is connected with the controller and used to send control parameters to the controller;

[0085] The computer is also connected with the signal acquisition and processor for receiving the echo signal;

[0086] The computer is also connected with the positioner for controlling the position and angle of the workpiece;

[0087] Described microwave source refers to all kinds of microwave generators that can generate microwave si...

Embodiment 3

[0108] refer to figure 1 , the inspector installs the workpiece to be detected on the positioner, and turns on the computer, microwave source, signal acquisition and processor, positioner, power divider, and microwave power amplifier power supply. At this time, the controller-T / R component The initial state is the receiving state.

[0109] Further, inspectors open the inspection software and input corresponding microwave frequency, frame rate, scanning angle range, microwave power and other parameters according to the inspection process and workpiece conditions.

[0110] Further, the inspector sets the corresponding frequency on the microwave source and turns on the microwave output switch according to the above microwave frequency value;

[0111] Further, the inspector sets corresponding parameters on the microwave power amplifier according to the microwave power value set on the inspection software, and opens the output channel of the amplifier;

[0112] Further, the inspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com