An electrothermal micro-drive control optical circuit on-off device based on u+v structure

A technology of micro-drive and control of light, applied in optics, optical components, instruments, etc., to achieve the effect of good system compatibility, accurate positioning, and effective on-off control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

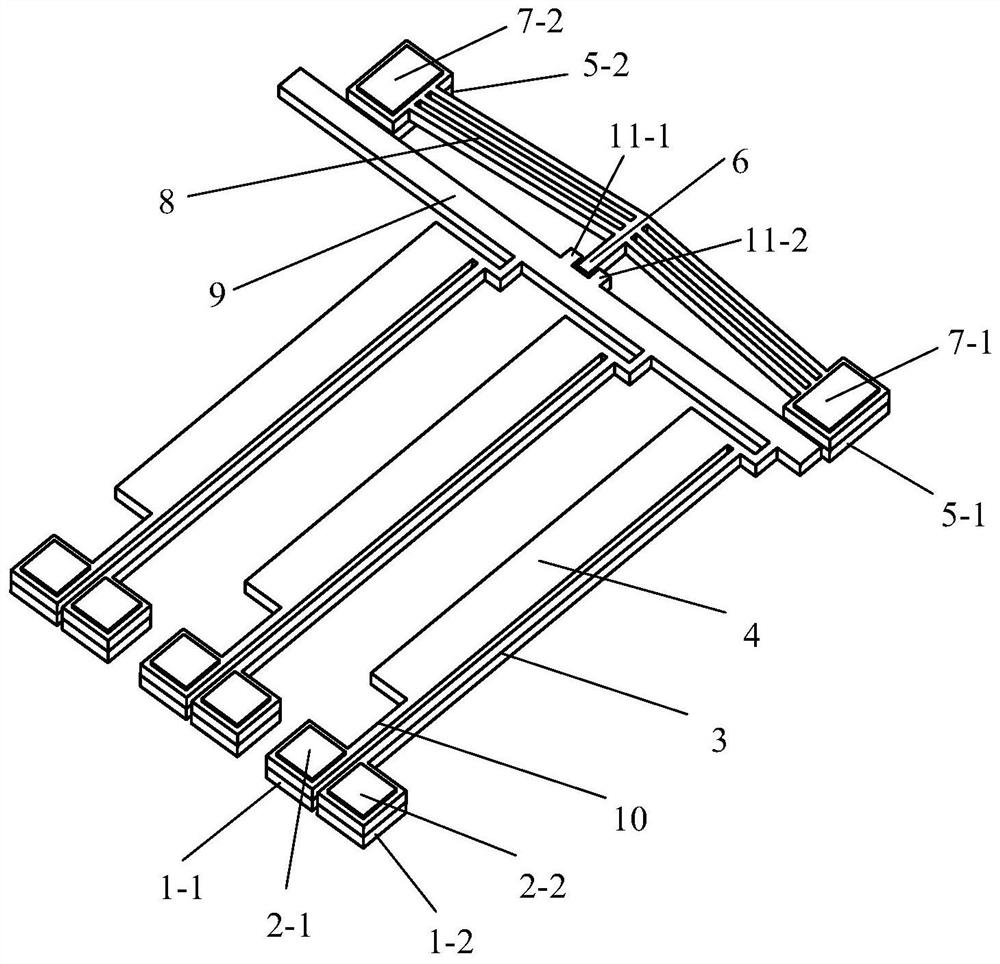

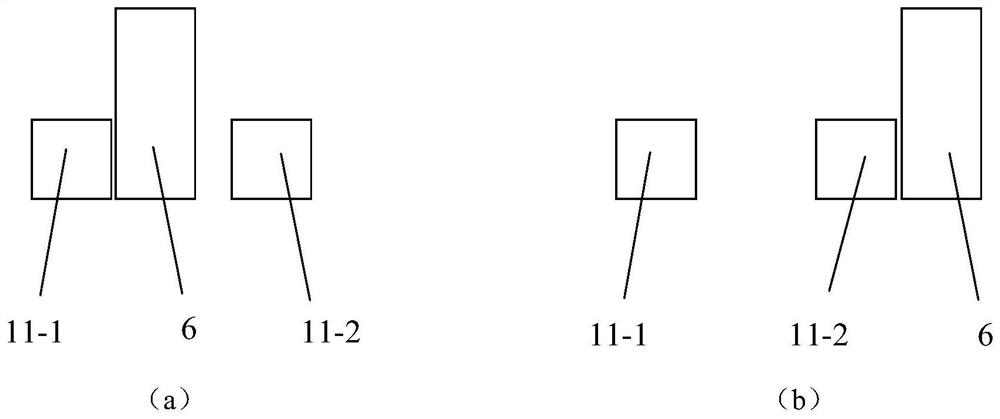

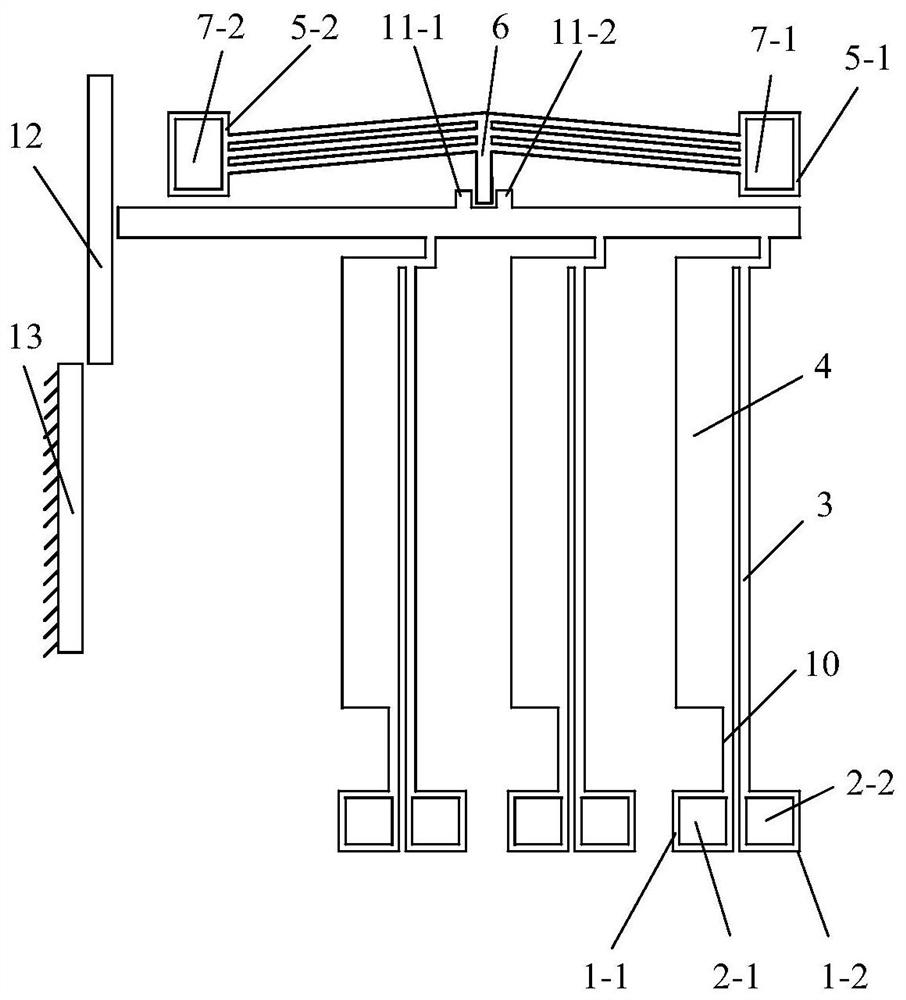

[0033] combine figure 1 , the present invention is based on the electrothermal micro-drive control optical path on-off device of U+V structure, including a driving mechanism and a locking mechanism;

[0034] The drive mechanism includes a driver composed of N U-shaped cantilever beams cascaded in phase, N pairs of U-shaped cantilever beam anchor points, and N pairs of U-shaped cantilever beam electrode patches; wherein, each U-shaped cantilever beam includes: located in the U-shaped structure The hot arm 3 on one side, the cold arm 4 and the flexible arm 10 on the other side of the U-shaped structure, wherein one end of the cold arm 4 is connected to one end of the hot arm 3, and the other end of the cold arm 4 is connected to one end of the flexible arm 10 ; Every pair of U-shaped cantilever beam anchor points includes a first anchor point 1-1 and a second anchor point 1-2, the other end of the flexible arm 10 is fixedly connected to the first anchor point 1-1, and the other ...

Embodiment 2

[0038] On the basis of Example 1, the thermal arm 3 located on one side of the U-shaped structure is a double thermal arm, including a first thermal arm 3-1 and a second thermal arm 3-2 in parallel, as Figure 6 As shown, one end of the first thermal arm 3-1 and one end of the second thermal arm 3-2 are connected to one end of the cold arm 4, and the other end of the first thermal arm 3-1 is fixedly connected to the second anchor point 1- 2. The other end of the second thermal arm 3-2 is fixed to the third anchor point 1-3, and the second anchor point 1-2 and the third anchor point 1-3 are respectively fixed to the second electrode patch 2-2 1. The first electrode patch 2-1.

[0039] The invention realizes the effective control of the optical path switch through the logical cooperation of the U-shaped cantilever beam electrothermal micro-drive mechanism and the V-shaped cantilever beam locking mechanism, and can further realize the effective on-off control of the high-energy o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com