Trench-fs type IEGT structure and manufacturing method thereof

A manufacturing method and junction depth technology, applied in the Trench-fs type IEGT structure and manufacturing field, can solve the problems of gate oscillation, gate peak value, small anode injection dose, etc., and achieve the effect of increasing loss and suppressing gate voltage peak value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

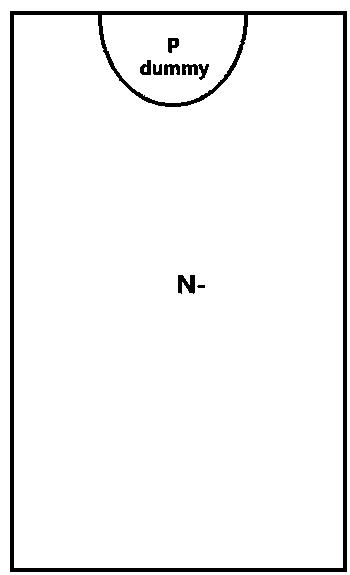

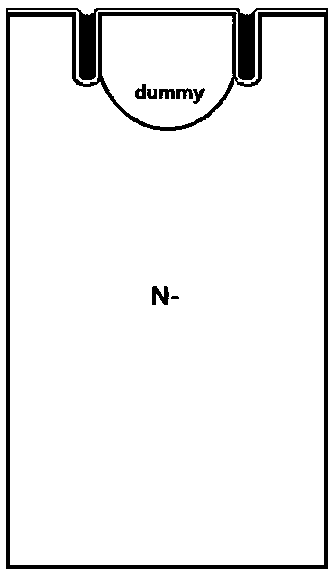

[0038] The invention relates to a method for manufacturing a Trench-fs type IEGT structure, mainly by changing the structure of the collector, without increasing the hole injection efficiency of the collector, and suppressing the peak value of the gate voltage during the short circuit, which is beneficial to Trench-fs The switching characteristics and short-circuit characteristics of the type IEGT are compromised. The manufacturing method of the Trench-fs type IEGT structure is to inject the collector twice to form segmented collectors with different junction depths, and the photoresist used to form the p++ region on the back is the same Zhang Ban obtained a Trench-fs type IEGT structure capable of compromising switching and short-circuiting.

[0039] Specifically manufactured by the following steps:

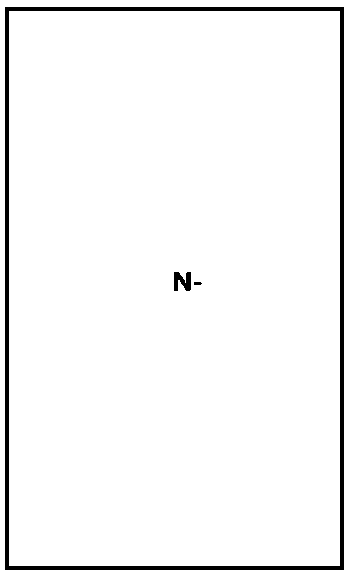

[0040] Step 1: First select a silicon wafer with a suitable N-type r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com