Longitudinal automobile power assembly adopting rear suspension

A technology of automotive powertrain and rear suspension, applied in the direction of power unit, control device, vehicle components, etc., can solve the problem of low stiffness, unfavorable powertrain roll and yaw limit, poor NVH performance, etc. problems, to achieve the effect of improving applicability, improving stiffness and multi-directional limit effect, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

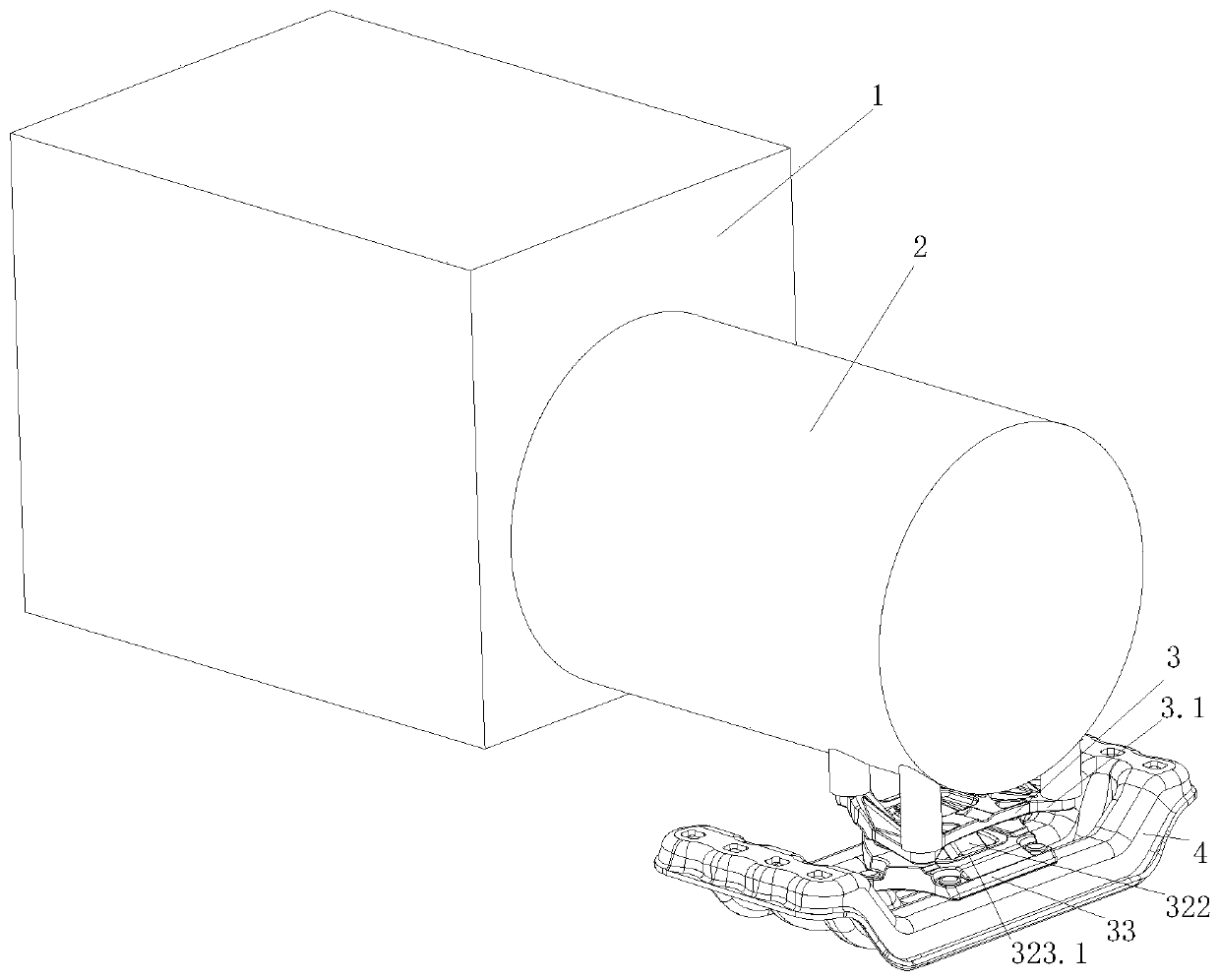

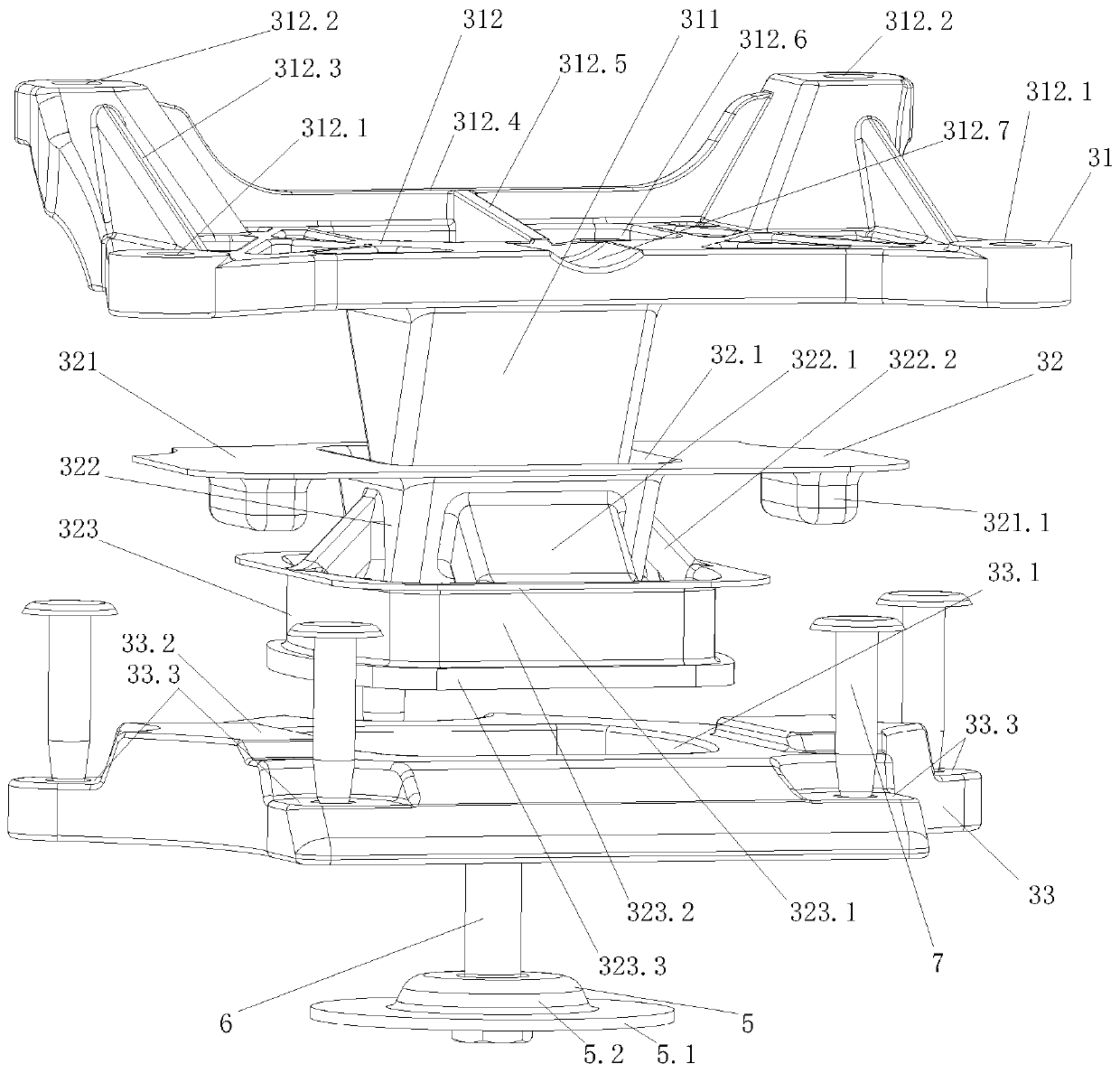

[0020] like figure 1 , figure 2 As shown, the present invention includes an engine 1 , a gearbox 2 , a rear suspension cushion 3 , a limit washer 5 , a washer bolt 6 , and a connecting bolt 7 that are integrally connected in an axial direction. Wherein the washer bolt 6 is preferably a knurled bolt. The front end of the engine is arranged in the front end of the nacelle, and the rear suspension mounting beam 4 is horizontally arranged in the rear end of the nacelle along the left and right directions, and the axis of the gearbox is perpendicular to the rear suspension mounting beam. The limit washer is provided with a through hole adapted to the washer bolt. The rear suspension cushion includes an upper bracket 31 , a main spring 32 and a lower bracket 33 .

[0021] The left and right ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com