Thermoset polymer processing, healing and welding methods

A technology of polymer materials and processing methods, applied in the field of polymer materials, can solve problems such as high cost, limited application, and incompatibility of polymer systems, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

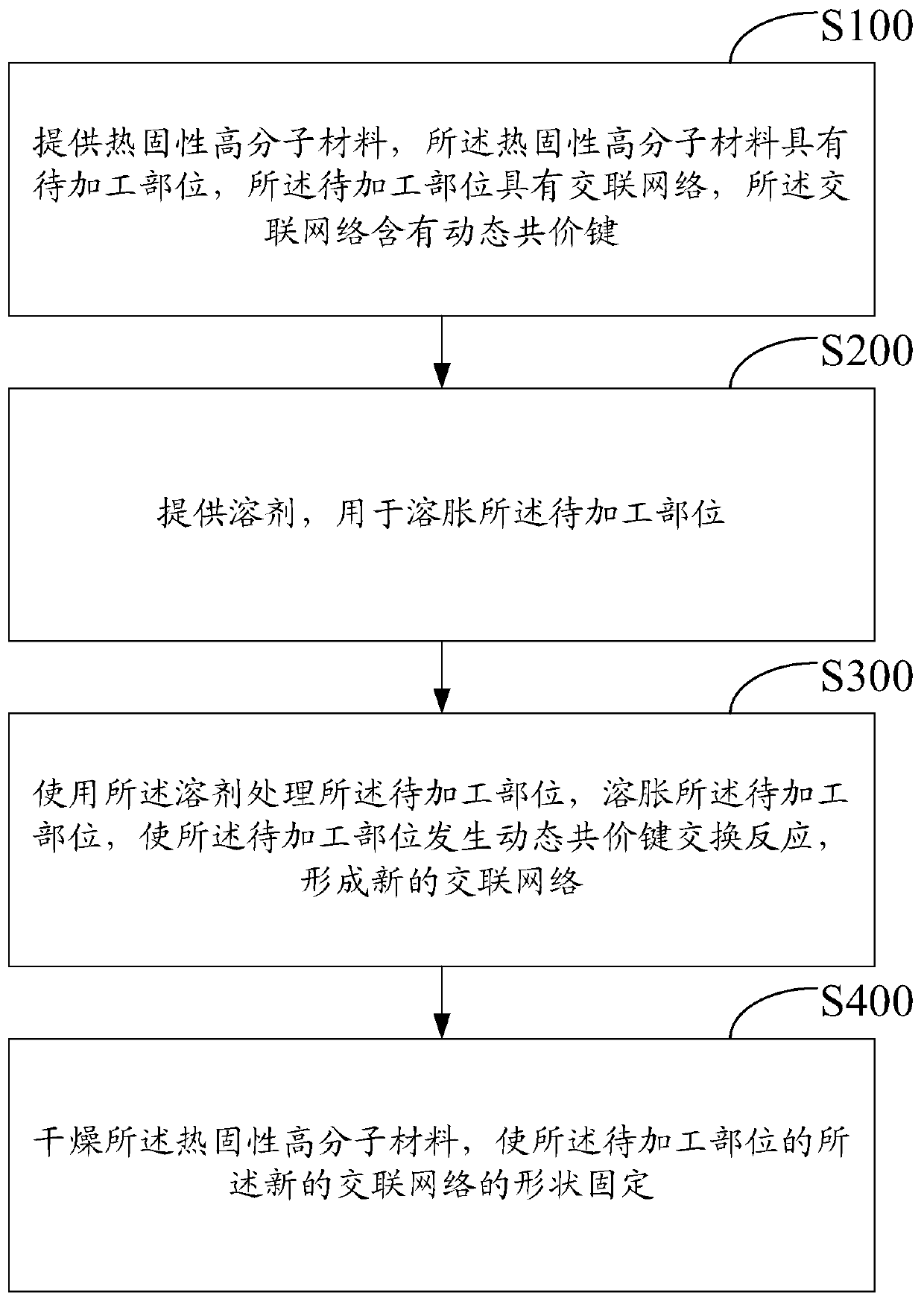

Method used

Image

Examples

Embodiment 1

[0076] The preparation of embodiment 1 thermosetting epoxy resin

[0077] Prepare a mixture of bisphenol A diglycidyl ether, adipic acid and transesterification catalyst 1,5,7-triazabicyclo[4.4.0]dec-5-ene (TBD) at a molar ratio of 1:1:0.1 ;

[0078] Melt the mixture at 180°C and stir to mix evenly;

[0079] Put the melted mixture in a mold, keep the temperature constant until the system begins to gel, then place the system under 5 MPa and heat press, and continue to solidify for 4 hours to completely react bisphenol A diglycidyl ether with adipic acid to obtain Thermosetting epoxy resin containing ester linkages. Wherein, the mold is a self-made mold with a square hole in the middle, which is used to prepare the thermosetting epoxy resin system into a square film. The mold can be an aluminum sheet with a thickness of 0.2mm. The prepared square film structure is used as the initial thermosetting epoxy resin material 10 .

Embodiment 2

[0080] Example 2 Healing of thermosetting epoxy resins

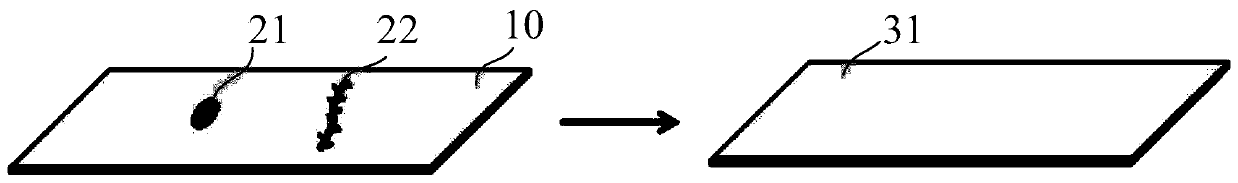

[0081] see figure 2 , prick the needle hole 21 or scratch on the surface of the initial thermosetting epoxy resin material prepared in Example 1 with a sharp instrument to produce a scratch 22;

[0082] Apply THF solvent on the corners to make the pinholes 21 and scratches 22 swell;

[0083] The THF solvent is volatilized, and the pinholes 21 and the scratches 22 are healed after the THF solvent is fully utilized, and a cured thermosetting epoxy resin material 31 is obtained.

[0084] After the above-mentioned healing, the thermosetting epoxy resin material 31 is warmed up to the glass transition temperature (T g ), such as above 80 ℃, the healing form remains unchanged.

Embodiment 3

[0085] The welding of embodiment 3 thermosetting epoxy resin

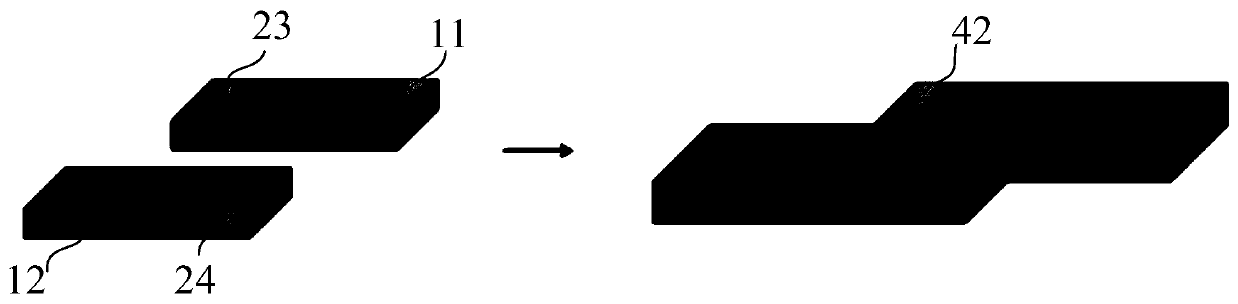

[0086] see image 3 , providing two initial thermosetting epoxy resin materials prepared in Example 1, i.e. the first initial thermosetting epoxy resin material 11 and the second initial thermosetting epoxy resin material 12;

[0087] Make the first welding part 23 and the second welding part 24 overlap and contact, and apply pressure to compress each other;

[0088] Apply THF solvent on the contact part to make the contact part swell;

[0089] The THF solvent is volatilized, and after the THF solvent is fully utilized, the first initial thermosetting epoxy resin material 11 and the second initial thermosetting epoxy resin material 12 are welded together to form an integrated welded thermosetting epoxy resin material 42 .

[0090] After the above-mentioned welding, the thermosetting epoxy resin material 42 is heated to the glass transition temperature (T g ), such as above 80 ℃, the welding part will not loosen....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com