A high-temperature steel slag modifier and modification pretreatment process

A technology of pretreatment and modifier, applied in the direction of manufacturing converters, etc., can solve the problems of poor pretreatment effect of steel slag modification, reduce the basicity and free CaO content of steel slag, improve gelling activity, and reduce silicate content. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The high-temperature steel slag modifier in this embodiment is composed of coal powder with an elemental carbon content of 83% and silicon powder with an elemental silicon content of 72%. The particle size of the coal powder is 0.5-1.5 mm, and the particle size of the silicon powder is 1-2 mm.

[0049] The amount of coal powder added is 0.2% of the weight of steel slag, the total amount of silicon powder added is 5% of the weight of steel slag, that is, the actual amount of elemental C added is 0.166% of the weight of slag, and the actual amount of elemental silicon added is 3.6% of the weight of slag.

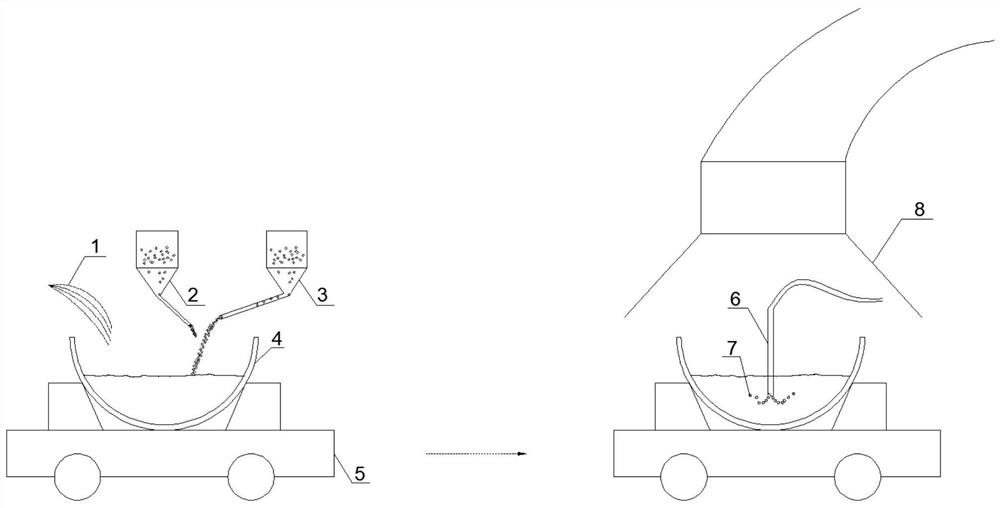

[0050] Such as figure 1 As shown, the flatbed truck carrying the slag tank goes under the furnace mouth of the converter, and the converter 1 starts to discharge slag. At the same time, a hopper equipped with a modifier is installed next to the slag tank. The silicon-containing substance A and the elemental carbon-containing substance in the modifier B is stored in Modi...

Embodiment 2

[0072] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that:

[0073] In this embodiment, the modifying agent is composed of activated carbon with 91% elemental carbon content and industrial silicon with 93% elemental silicon content. The particle size of activated carbon is 1-2 mm, and the particle size of industrial silicon is 1-2 mm;

[0074] The amount of activated carbon added is 0.27% of the weight of steel slag, the total amount of industrial silicon added is 5.4% of the weight of steel slag, that is, the actual amount of elemental C added is 0.25% of the weight of slag, and the actual amount of elemental silicon added is 5% of the weight of slag;

[0075] Step 3) The pressure of nitrogen blowing is 0.7MPa.

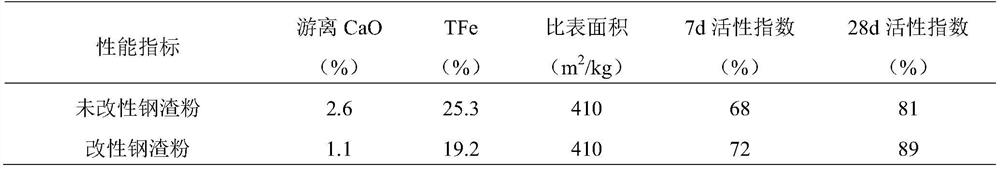

[0076] The pretreated steel slag is then magnetically recovered for elemental iron. After the steel slag is finely powdered, the test results according to the standard GB / T20491-2006 "Steel slag powder used in cement ...

Embodiment 3

[0081] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that:

[0082] In this embodiment, the modifying agent is composed of bituminous coal with an elemental carbon content of 85% and ferrosilicon with an elemental silicon content of 75%. The particle size of bituminous coal is 0.5-2.0 mm, and the particle size of ferrosilicon is 1-2 mm;

[0083] The amount of bituminous coal added is 0.35% of the weight of steel slag, the total amount of ferrosilicon added is 4% of the weight of steel slag, that is, the actual amount of elemental C added is 0.3% of the weight of slag, and the actual amount of elemental silicon added is 3% of the weight of slag;

[0084] Step 3) The pressure of nitrogen blowing is 0.5MPa.

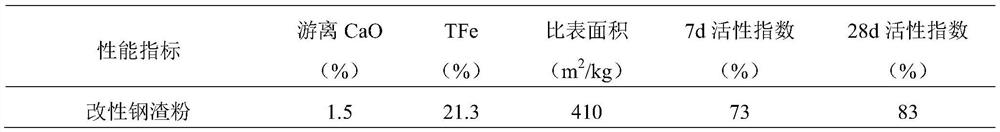

[0085] The pretreated steel slag is then magnetically recovered for elemental iron. After the steel slag is finely powdered, the test results according to the standard GB / T20491-2006 "Steel slag powder used in cement and conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com