A push-chain concrete sprayer

A concrete spraying machine and push-chain technology, applied in the field of concrete spraying equipment, can solve the problems of difficult moving process, time-consuming and labor-intensive, labor-intensive construction personnel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

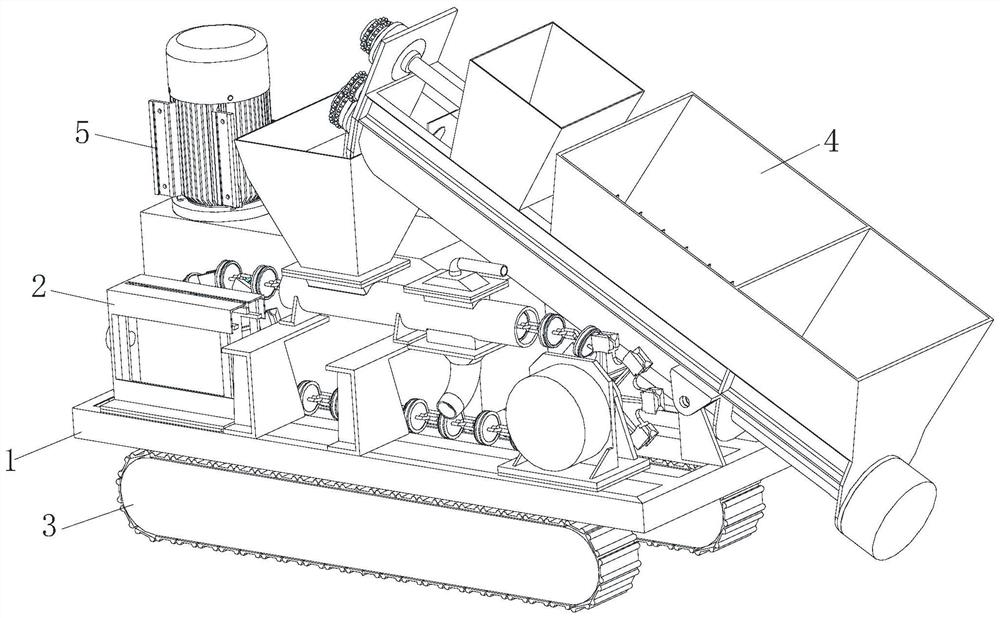

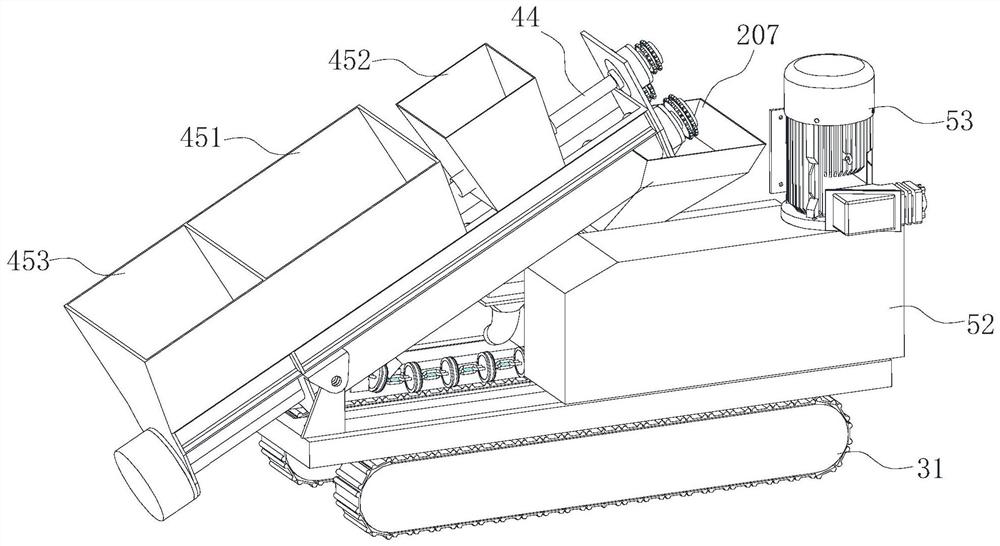

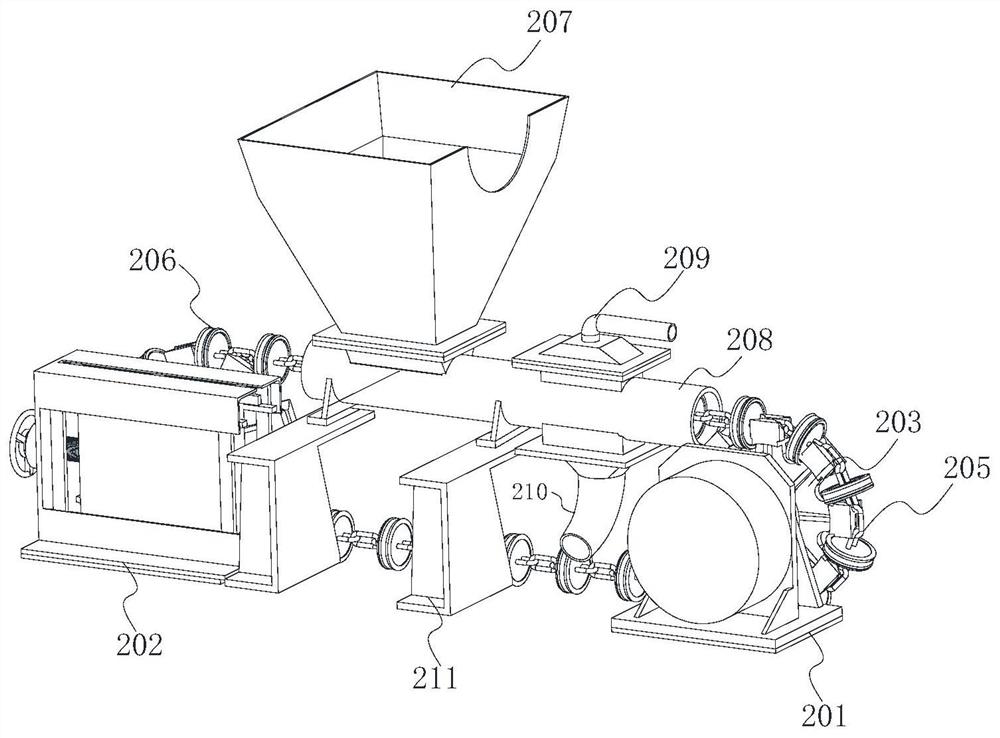

[0029] combine Figure 1 to Figure 10 As shown, the specific implementation of a kind of push chain type concrete sprayer provided by the present invention is as follows.

[0030] A kind of push chain type concrete spraying machine is specifically as follows figure 1 As shown, it specifically includes a frame 1, a traveling mechanism 3, a spraying mechanism 2, a screw feeding mechanism 4 and a hydraulic mechanism 5. The traveling mechanism 3 is fixedly connected with the frame 1, the spraying mechanism 2 is arranged on the frame 1, the screw feeding mechanism 4 is connected with the hopper of the spraying mechanism 2, and the hydraulic mechanism 5 provides power for each mechanism. The concrete sprayer realizes the proportioning of materials through the screw feeding mechanism 4, and at the same time, the materials are directly stirred through the main screw shaft during the proportioning process, and after the mixing is even, the materials are directly sent to the hopper of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com