Magnetic suspension bearing stator, magnetic suspension bearing, motor, compressor and air conditioner

A bearing stator and magnetic suspension technology, which is applied in the fields of magnetic suspension bearing stator, motor, magnetic suspension bearing, compressor and air conditioner, can solve the problems of shell deformation, low reliability and unsatisfactory coaxial accuracy, and achieves the reduction of The amplitude of small high-frequency vibration, improving the matching accuracy, and avoiding the effect of multiple disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

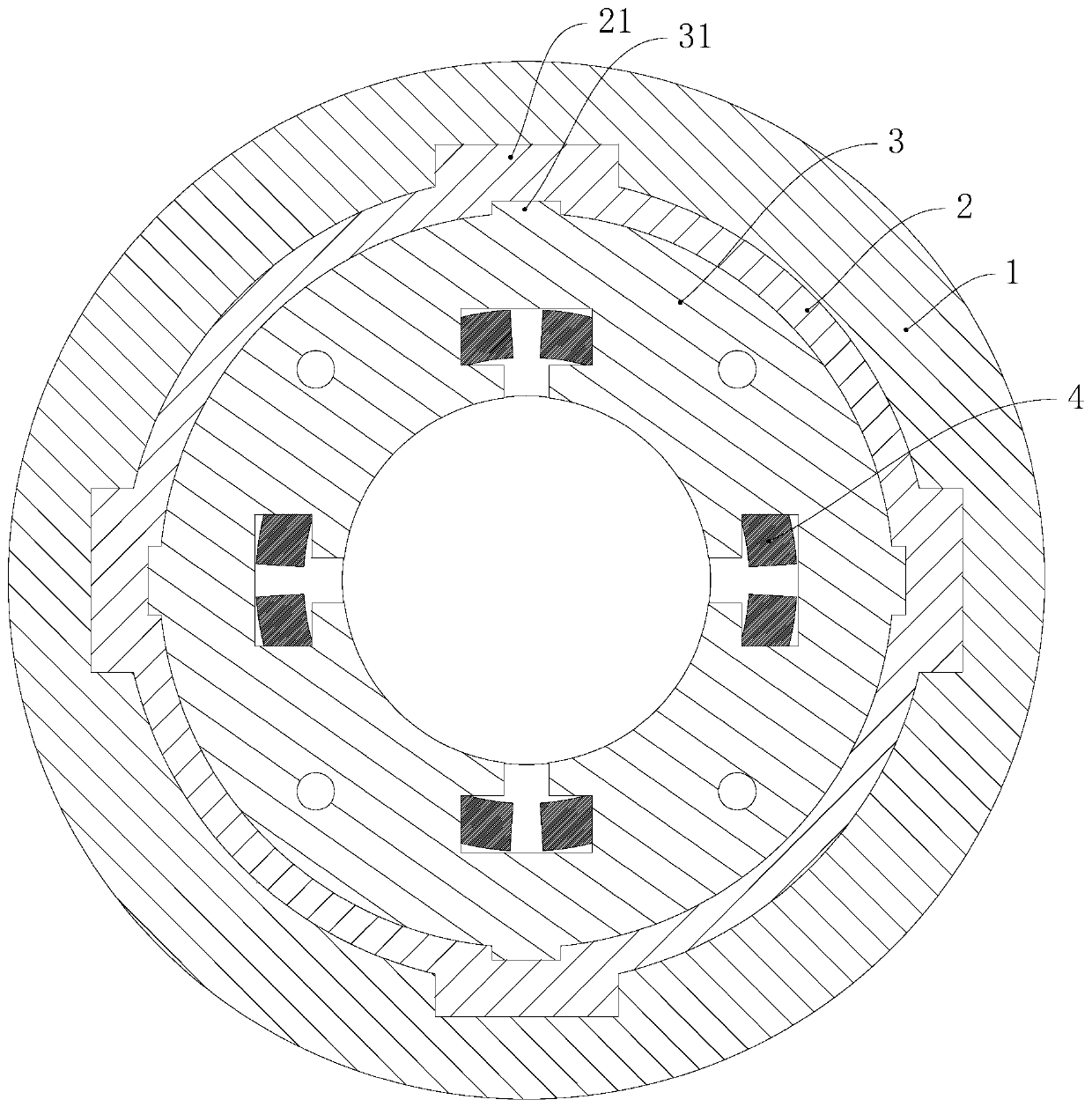

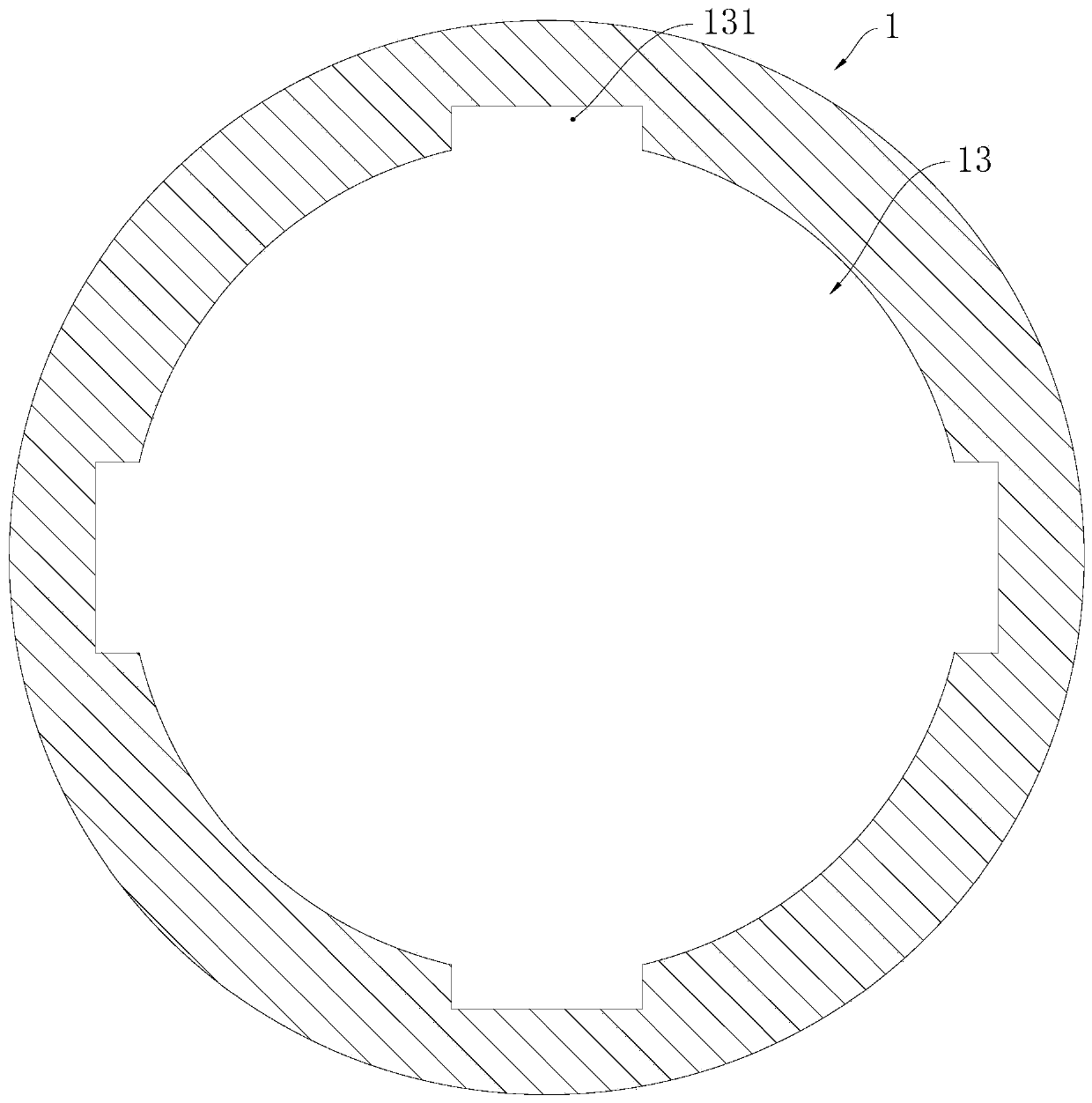

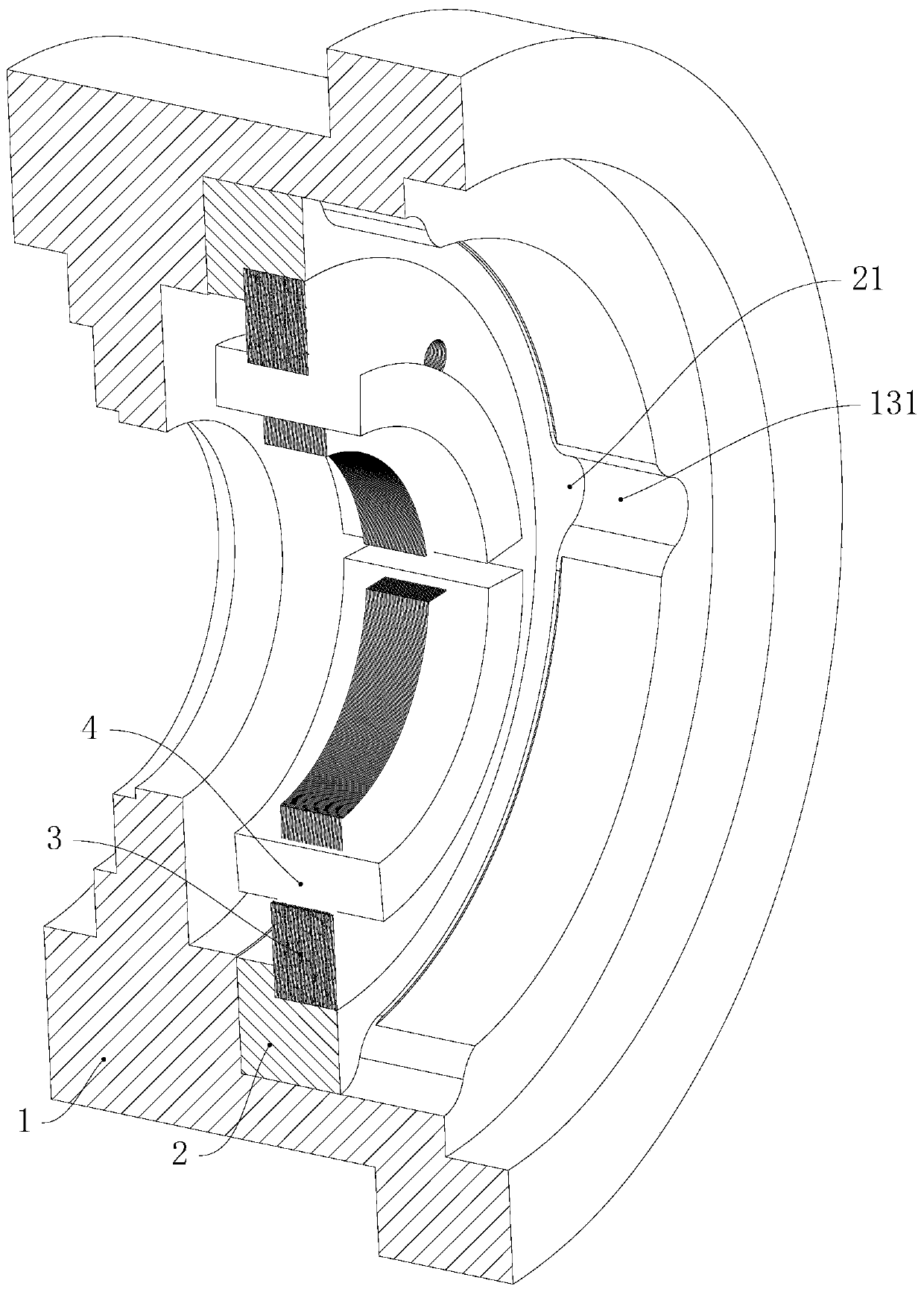

[0049] The air conditioner of this embodiment adopts the compressor of this embodiment, the compressor of this embodiment includes the magnetic suspension bearing of this embodiment, the motor of this embodiment includes the magnetic suspension bearing of this embodiment, and the magnetic suspension bearing of this embodiment includes a rotor and The magnetic suspension bearing stator of this embodiment. Please refer to Figures 1 to 4 , The magnetic suspension bearing stator in this embodiment includes a housing 1 and a stator assembly, the housing 1 has an installation cavity 13 , and the stator assembly is installed in the installation cavity 13 .

[0050] Please refer to figure 1 and Figure 4 , the stator assembly includes a connecting ring 2, a stator core 3 and a stator winding 4, the stator winding 4 is wound on the stator core 3, the outer peripheral wall of the stator core 3 is in interference fit with the inner peripheral wall of the connecting ring 2, and the con...

Embodiment 2

[0060] Please refer to Figure 5 and Figure 6 , in the magnetic suspension bearing stator of this embodiment, along the axial direction of the magnetic suspension bearing stator, the installation cavity 13 is formed between the first side wall 11 and the second side wall 12, and the stator assembly is installed in the installation cavity 13, along the stator assembly One end in the axial direction is in contact with the first side wall 11 , and the other end of the stator assembly in the axial direction is in contact with the second side wall 12 , the first side wall 11 and the second side wall 12 limit the movement of the stator assembly in the axial direction. Specifically, after the stator assembly is assembled, the casing 1 is formed on the stator assembly by die-casting, and the casing 1 is cooled and shrunk to achieve the purpose of interference fit between the casing 1 and the connecting ring 2 .

[0061] In this way, the stator assembly is restricted by the first sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com